Texas A&M University is joining a new National Science Foundation (NSF) Engineering Research Center (ERC), led by Northwestern University, seeking to develop robots capable of enhancing human labor.

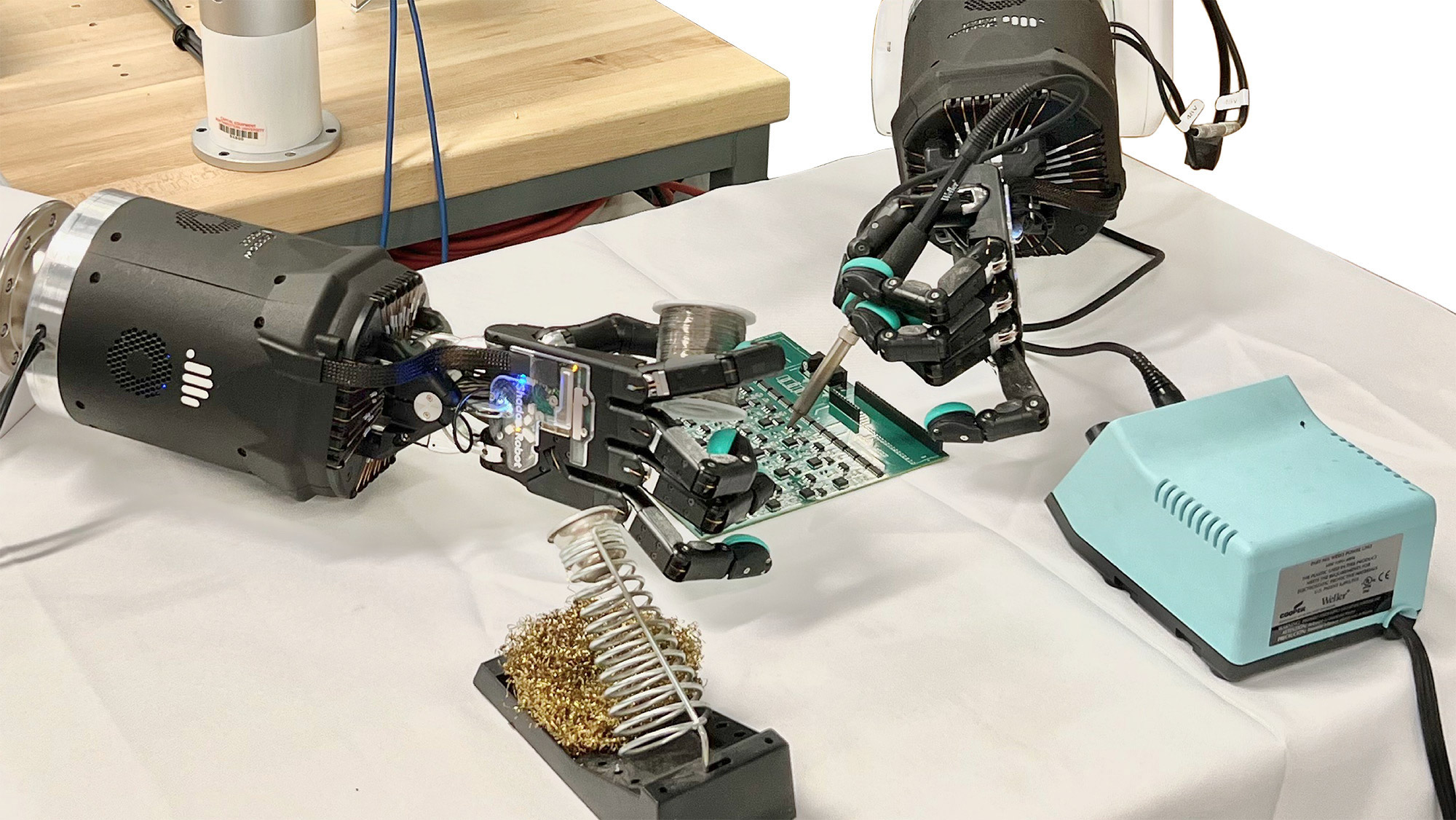

A central goal of the Human AugmentatioN via Dexterity (HAND) center is to make robotic assistance accessible and applicable to a wide range of physical actions through an engineered system of dexterous robotic hands, AI-powered fine motor skills, human interface, as well as developing the workforce and training for the future.

The five-year, $26 million grant also includes Carnegie-Mellon University and Florida A&M University, with faculty support from Syracuse University, the University of Wisconsin-Madison and the Massachusetts Institute of Technology. The center’s NSF grant has the potential to be renewed for another $26 million for an additional five years. Founded in 1985, the NSF ERC program supports U.S. universities conducting convergent research, education and technology translation aimed at creating substantial societal impacts.

“We are excited to be a part of this groundbreaking initiative that will redefine the future of work and push the boundaries of technology to make a tangible impact,” said Dr. Robert H. Bishop, vice chancellor and dean for Texas A&M Engineering. “At Texas A&M, we believe in harnessing innovation to solve pressing problems and improve lives.”

We are excited to be a part of this groundbreaking initiative that will redefine the future of work and push the boundaries of technology to make a tangible impact. At Texas A&M, we believe in harnessing innovation to solve pressing problems and improve lives.

Dr. Cynthia Hipwell, Oscar S. Wyatt, Jr. ’45 Chair II Professor in the J. Mike Walker ’66 Department of Mechanical Engineering, will serve as a deputy director for the HAND center.

Hipwell said that current robotic tools typically require specialized expertise and an expensive integration process and thus are limited to high-volume, highly repeatable operations. The center’s approach in creating robotics that adaptably perform many different tasks and are easy for workers to use could provide affordable support to address labor shortages in manufacturing and caregiving, as well as food processing, handling precious or dangerous materials and more.

“Our vision is that it will be like the transition from mainframe computers used by specialized programmers to the arrival of the Apple Macintosh or PC [personal computer] as a tool that everybody could use,” said Hipwell. “We have many small and medium enterprises around our country that haven't been able to benefit from automation technology. We want to create something that workers can use as a tool to complete their work. That's really our vision — democratizing access to robotics.”

To achieve the goal of providing a practical and easily accessible tool, researchers have divided their work into three main areas:

- Hands: sensing, actuation, and design

- Intelligent dexterity: simulation, representation, and control

- Human interface: multimodal interface, no-code programming, and social/legal/industrial studies

The center will also develop workforce training materials and an intuitive training interface enabling human operators of all education levels to teach the robots how to perform their necessary tasks.

“The idea is that these tools could be something that any of us could use,” said Hipwell. “This could be something that could help a worker with physical work, or it could help someone stay in their home longer because they have physical assistance with some of their tasks. It could even be brought into areas where the work is dangerous and offer a way to help someone do physical work less dangerously.”

The HAND center brings together experts in various fields, including materials, manufacturing, manipulation, soft robotics, artificial intelligence, machine perception, modeling, haptics, human-robot interaction, participatory design and research, team science, education, law and the social sciences.

“To make a breakthrough in this area, you can't just move one aspect of it forward — just actuators or just control algorithms or just interface mechanisms. I think making a breakthrough requires this coordinated system approach,” said Hipwell. “We have the opportunity with this system-focused effort to make a much larger impact than we would as individual researchers working alone.”

In addition to Hipwell, several Texas A&M researchers will contribute to the center’s focus areas. Dr. Debra Fowler, executive director of the Center for Teaching Excellence, will lead overall workforce development programs for the center, leading the creation of programs of study for future leaders in the field and programs for technicians, workers, and K-12 and community college outreach. Dr. Robert Ambrose will lead the High Consequence Materials Handling Testbed, which will help the center partner with collaborators such as NASA and Los Alamos National Laboratory on specific applications of HAND technology. Drs. Rebecca Friesen and Taylor Ware will contribute to the human interface and hands research areas, and Dr. Mohamed Gharib will lead unique K-12 and community college outreach programs.