Equipment Details

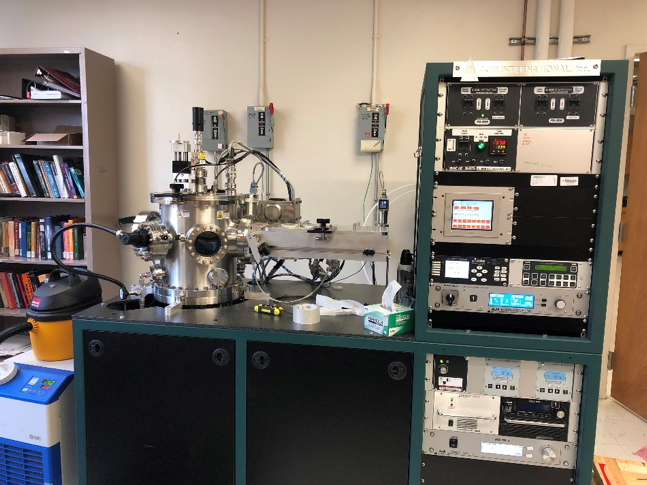

Sputtering System (AJA Orion 5)(DRTY 108)

AJA International ATC Orion Series Sputtering Systems are compact versions of the popular ATC Flagship Series physical vapor deposition tools designed to deliver maximum performance for limited budgets. These HV and UHV systems inherit many design features and common parts from the highly evolved ATC sputtering tools. The standard ATC Orion modules (chambers, frames, cluster flanges, etc.) are generally in stock at AJA thereby reducing delivery times.

A special version of the Orion 8 is also available that features (4) 2" magnetron sputtering sources with in-situ tilt capability. ATC Orion Systems can also be easily connected to each other or to other ATC Systems for multi-chamber (e.g. metal/oxide) or multi-technique (e.g. sputter/evaporation/PLD/ion milling) configurations.

Specifications:

- Five 2” sputter guns

- Quartz crystal thickness monitor

- Substrate holder:

- Substrates up to 4” diameter

- Continuous motorized rotation (0-20 RPM) with controller

- Radiant heating to 850 ℃ with quartz halogen lamps

- Substrate RF bias during Sputter Deposition

- Computer control

- Deposition Uniformity: Better than +/- 2.5% over a 4” diameter wafer

- Base Vacuum: Better than or equal to 5.0x10^-8 Torr

- Pumpdown to 5x10^-7 Torr in 30 minutes or less from clean, dry, and empty after N2 vent

- Maximum deposition rates for Ti (2 Å/sec) and SiO2 (0.5 Å/sec)

Atomic Layer Deposition (ALD) System (JCAIN 321)

The Ultratech / Cambridge NanoTech Savannah S200 ALD System delivers outstanding deposition results and provides maximum experimental flexibility for ALD research, development and production applications. It allows atomic-level control over the thickness (sub nanometer to tens of nanometer) and composition of the deposit on material surface. It is capable of thin-film deposition or coating on particles or porous materials. Three precursors are currently available enabling the deposition of TiO2, MgO, and Al2O3. Other precursors are available upon request. It is location at JCAIN 321.

Specifications:

- Deposit on flat substrates up to 200mm in diameter

- Maximum substrate temp - 350 C

- Deposition uniformity < 1% (Al2O3)

- UP to 6 lines available for precursors

- Particle coating attachment

- Ozone generator

Cress Double Furnace (JCAIN 320)

The Cress Double Furnace (Dual Chamber Furnace, C2121) provides two separately controlled heating chambers within a minimum floor space. The furnace is designed for hardening the surface. The two chambers allow immediate tempering or drawing after quench without waiting for the hardening furnace to cool to the lower temperature required.

Specifications:

Upper Chamber- Maximum intermittent temperature: 2250 °F

- Maximum continuous temperature: 2100 °F

- Maximum intermittent temperature: 1250 °F

- Maximum continuous temperature: 1100 °F

- Controls: Autotuning microprocessor-based controls with ¼ of 1% accuracy.

- Heating element: Alloy wire elements coiled and mounted on the side walls.