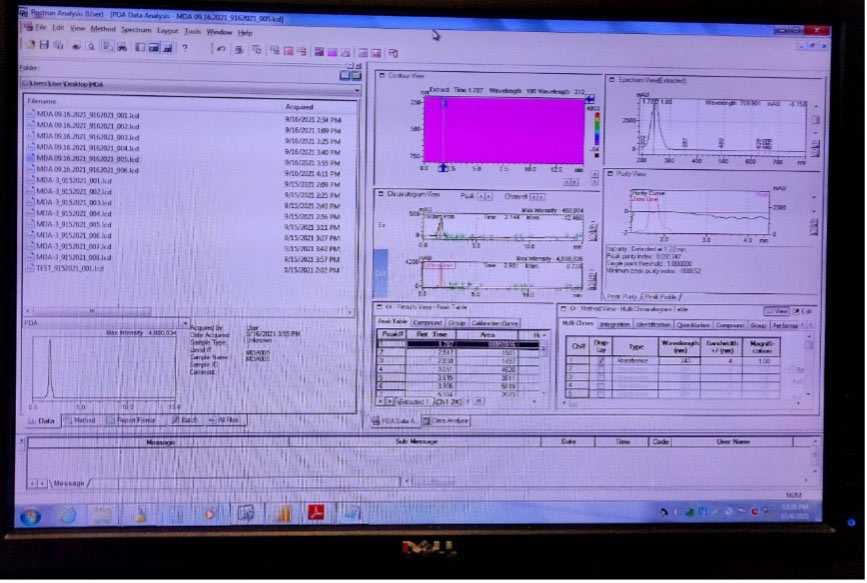

High-Performance Liquid Chromatography (HPLC) (JCAIN 321)

The Shimadzu LC-2030C system equipped with a UV/Vis detector is highly reliable for separation and quantification of organic chemicals in water. The employment of an autosampler makes it easy to be operated. Purification columns currently available include TSKgel ODS-80Ts (2x250 mm, 5 µm), Restek 558389 (4.6x50 mm, 3 µm), and Kinetex Core-shell C18 (3x50 mm, 2.6 µm). It is located at JCAIN 321.

Specifications:

MicroClimate Environment Chamber (JCAIN 308)

MicroClimate chambers operate at a wide range of temperature and/or humidity conditions. You may program for temperature cycling tests or maintain steady-state temperature environments.

Specifications:

- Temperature Range: -73 °C (-100 °F) to +190 °C (+375 °F)

- Humidity Range: 10 % to 95 % RH

- Control Stability: ±0.5 °C from -50 °C to +190 °C, ±1 °C below -50 °C, at steady-state conditions after stabilization.

- Temperature performance: Temperature pulldown from +24 °C (+75 °F) to:-40 °C(-40 °F) in 22 minutes-54 °C(-65 ° F) in 32 minutes-68 °C(-90 ° F) in 48 minutes

- Temperature heat-up from:+24 °C (+75 °F) to +94 °C (+200 °F) in 6 minutes+24 °C (+75 °F) to +190 °C (+375 °F) in 18 minutes-34 °C (-30 °F) to +24 °C (+75 °F) in 7 minutes-65 °C (-90 °F) to +24 °C (+75 °F) in 8 minutes

- Live load capacity: 350 watts at -40 °C (-40 °F)250 watts at -54 °C (-65 °F)

- Interior dimensions: 17" wide × 17" deep × 18" high(43.2 cm wide × 43.2 cm deep × 45.7 cm high)

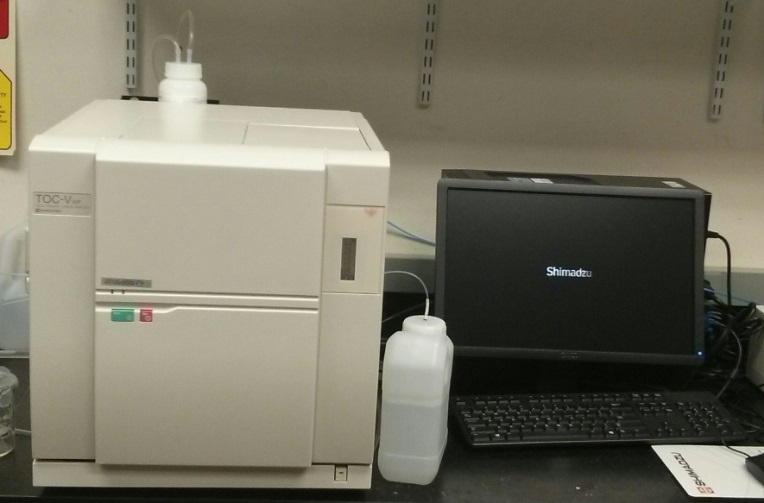

Total Organic Carbon (TOC) Analyzer (JCAIN 321)

The Shimadzu TOC-VWP analyzer is a newly designed wet oxidation instrument with enhanced sensitivity and accuracy. Powerful oxidation of water samples is achieved through a combination of peroxosulfuric acid, UV illumination, and heating. Total carbon (TC), Inorganic carbon (IC), Total organic carbon (TOC), and Non-purgeable organic carbon (NPOC) in water can be measured. It is located at JCAIN 321.

Specifications:

Learn more about the specifications for the Shimadzu TOC-VWP analyzer.

Wilson Rockwell 2000 Harness Testing Machine (JCAIN 308)

The Wilson Rockwell 2000 Hardness Testing Machine is a tester that measures hardness values with different hardness scales.

Specifications:

- Pre-load: 10kgf

- Main-load: 60, 100, 150kgf

- Hardness scales: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV, 15Y

- Test load type: Electronic closed-loop loadcell

- Test cycle type: Automatic, one-button start

- Vertical test capacity: 2002 models 10in [254mm] and 2003 models 14in [356mm]

- Horizontal test capacity: 8.5in [216mm]

- Indenters (optional): 120° Diamond cone, 1/16in, 1/8in, 1/4in, 1/2in

- Resolution: 0.1 or 0.01 HR (adjustable)

- Data-out: RS232

- Standard Compliant: ASTM E18, B254, ISO 6508, JIS Z2245

- Power: 100, 120, 220, or 240V AC +/- 10%, 47-63Hz

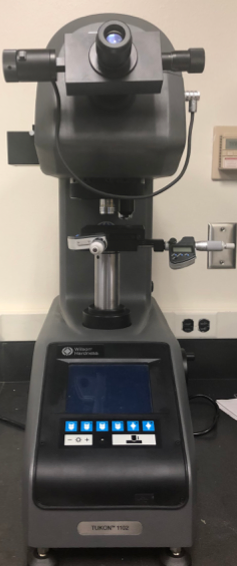

Wilson TUKON 1102 Micro-Hardness Tester (JCAIN 308)

The Wilson TUKON 1102 Micro-hardness Tester is used for Vickers or Knoop hardness testing by calculating hardness values from measurements of the diagonal lengths of indentations.

Specifications:

- Hardness scales: HV, HK

- Main-load: 10gf-1kgf (2kgf optional)

- Test cycle type: Motorized dead weight

- Vertical test capacity: 4.1in [130mm]/with XY-stage 3.7in [95mm]

- Horizontal test capacity: 5.1in [130mm]

- Objectives: 10x and 50x Regular

- Total magnification: 100x, 500x

- Indenters: 1 indenter position, select vickers or knoop

- Data-out: USB and RS232

- User interface: Multilanguage 4.7in LCD touchscreen

- XY-stage options: Manual 100x 100mm stage, 25x25mm travel motorized stage 100x 100mm travel (with PC software only)

- Camera software: Options available from basic camera kit to full automatic system. Contact your local Buehler representative for more information

- Standards compliant: ISO 6507, ASTM E384

- Power: 100-240V AC, 60/50Hz