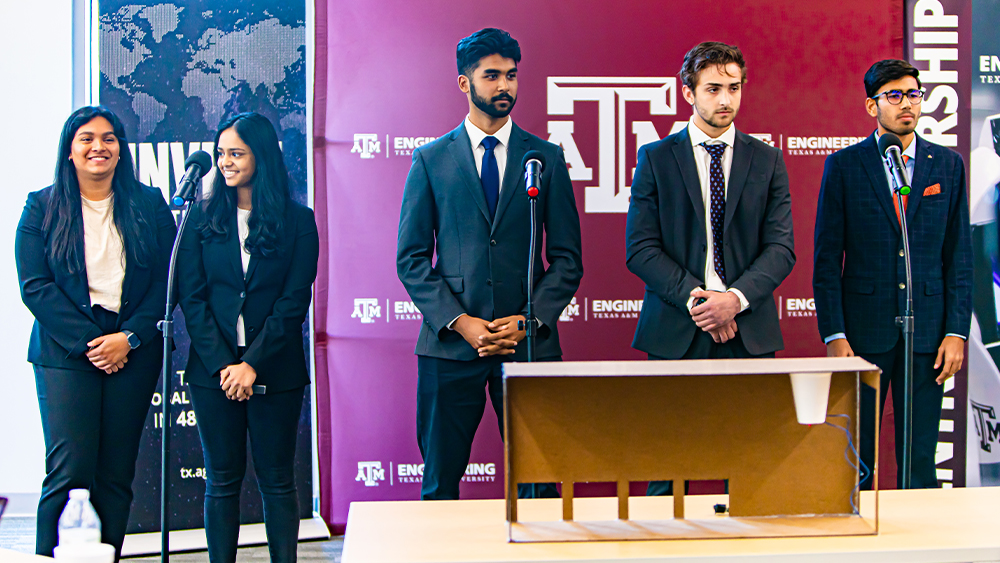

Innovation Nation team members included, from left, Mohammed Afif Kibbi, Chahatkumar Chaudhari, Ryan Sanchez, Ankit Shah, Likitha Joneboina and Shweta Kumaran. |

Image: Texas A&M Engineering/Jesus A. Reina

Texas A&M University recently hosted its fifth annual Invent for the Planet (IFTP) competition. This weekend-long event united students from over 20 universities worldwide to address some of the globe's most critical challenges.

Ankit Shah, a multidisciplinary engineering technology junior in the Department of Engineering Technology and Industrial Distribution, competed in the IFTP competition with their team, Innovation Nation. Team members included Likitha Joneboina and Shweta Kumaran from the Department of Computer Science and Engineering, Ryan Sanchez from the J. Mike Walker ’66 Department of Mechanical Engineering, Mohammed Afif Kibbi from the mechanical engineering program at Texas A&M University at Qatar, and Chahatkumar Chaudhari, a graduate student in the Department of Aerospace Engineering.

Each participating university simultaneously hosted a local, first-phase IFTP round where teams — formed based on similar interests in a need statement — could collaborate virtually through Microsoft Teams with their multinational peers.

Ankit Shah, a multidisciplinary engineering technology junior in the Department of Engineering Technology and Industrial Distribution, competed in the IFTP competition with their team, Innovation Nation. Team members included Likitha Joneboina and Shweta Kumaran from the Department of Computer Science and Engineering, Ryan Sanchez from the J. Mike Walker ’66 Department of Mechanical Engineering, Mohammed Afif Kibbi from the mechanical engineering program at Texas A&M University at Qatar, and Chahatkumar Chaudhari, a graduate student in the Department of Aerospace Engineering.

Each participating university simultaneously hosted a local, first-phase IFTP round where teams — formed based on similar interests in a need statement — could collaborate virtually through Microsoft Teams with their multinational peers.

From left: Shweta Kumaran, Likitha Joneboina, Ankit Shah, Ryan Sanchez and Chahatkumar Chaudhari stand behind their prototype of TexSort as they present their innovative solution to a panel of judges. |

Image: Texas A&M Engineering/Jesus A. Reina

During the first phase of the IFTP competition, students addressed challenges that cover various topics, including environmental sustainability, energy innovation, social justice, economic development in developing countries, and equitable access to resources.

"We were tasked with finding a way to reduce textile waste," Shah said. "We quickly realized that a lot of the waste happens in textile salvage facilities."

At the textile salvage facilities, unsold clothes are recycled, discarded or donated to other countries. The process is entirely manual, meaning workers may accidentally toss recyclable clothes or make other errors while sorting the vast quantities of garments.

Innovation Nation proposed TexSort, a machine that could be mounted onto the conveyor belts in textile salvage facilities to sort clothes into different bins based on their recyclability.

Shah shared how they applied what they learned from a class they took as an undergraduate in the engineering technology and industrial distribution department that helped them with the design and business aspects of TexSort.

"We were tasked with finding a way to reduce textile waste," Shah said. "We quickly realized that a lot of the waste happens in textile salvage facilities."

At the textile salvage facilities, unsold clothes are recycled, discarded or donated to other countries. The process is entirely manual, meaning workers may accidentally toss recyclable clothes or make other errors while sorting the vast quantities of garments.

Innovation Nation proposed TexSort, a machine that could be mounted onto the conveyor belts in textile salvage facilities to sort clothes into different bins based on their recyclability.

Shah shared how they applied what they learned from a class they took as an undergraduate in the engineering technology and industrial distribution department that helped them with the design and business aspects of TexSort.

Ankit Shah presents the advantages of their team’s innovation, TexSort, and how it would benefit society by reducing textile waste. |

Image: Texas A&M Engineering/Jesus A. Reina

TexSort would utilize spectrometry or an artificial intelligence camera to identify the quality and type of material, such as denim or cotton, and use that information to decide whether the item can be recycled. Any clothes that cannot be recycled would merely pass through the machine for an employee to determine whether to donate or discard, which is much more manageable than deciding on an article's recyclability.

Although Innovation Nation did not get selected to move to the next round, Shah shared that the experience the team gained was immensely valuable.

"This competition taught me that finding a solution to engineering challenges is not a simple process," Shah stated. "Many people need to be interviewed to find the root of a problem. From there, solutions need to be brainstormed, and many possible solutions could be scrapped. I'm glad I had this opportunity as an undergrad because most people are first exposed to problems like these after graduation."

Shah and their team were grateful for the opportunity to network and for the collaborative environment presented by the competition. They are enthusiastic about competing again next year to continue developing innovative solutions that could positively impact people from around the globe.

Although Innovation Nation did not get selected to move to the next round, Shah shared that the experience the team gained was immensely valuable.

"This competition taught me that finding a solution to engineering challenges is not a simple process," Shah stated. "Many people need to be interviewed to find the root of a problem. From there, solutions need to be brainstormed, and many possible solutions could be scrapped. I'm glad I had this opportunity as an undergrad because most people are first exposed to problems like these after graduation."

Shah and their team were grateful for the opportunity to network and for the collaborative environment presented by the competition. They are enthusiastic about competing again next year to continue developing innovative solutions that could positively impact people from around the globe.