Throughout the spring semester, 39 student teams in the Wm Michael Barnes ’64 Department of Industrial and Systems Engineering worked with government, industry and individual sponsors to address their project needs. The teams recently presented their work at the Engineering Project Showcase at Texas A&M University where several teams were recognized.

Dr. Michael Do, professor of practice and director of the capstone program, said the program enables students to apply everything they've learned from their undergraduate academic program to projects.

"I strongly believe our capstone course gives students a true understanding and appreciation for what it takes to engineer a system from a design process perspective, which will be important as they graduate and begin their professional careers,” Do said.

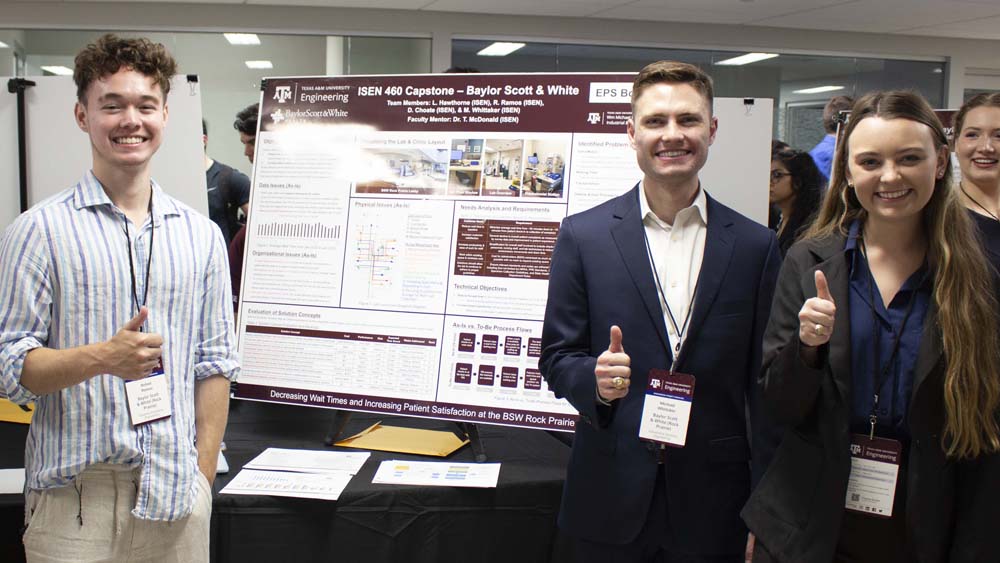

First place in the department was awarded to Dylan Choate, Lacey Hawthorne, Michael Whittaker and Rafael Ramos, who worked with sponsor Baylor Scott and White Health to address lab wait times at the Rock Prairie clinic location.

The team developed several diagrams and designed solutions to make the lab services more efficient and reduce wait times.

“They’re seeing an average wait time of up to about 30 minutes,” Whittaker said. “With the pandemic, it's just an increase in sick patients, a large increase of people coming in with or without COVID. They want to reduce that down to about 10 to 15 minutes based on what it used to be prior to COVID-19 and also increase patient satisfaction ratings.”

The team was able to make many trips to the clinic location to observe firsthand and traced paths that nurses must make for each patient, which can include unnecessary trips to the front window of the labs to explain to lost patients that they have to check in at a different desk.

Choate said the team calculated that there was approximately six minutes of non-value-added time for each patient. After reviewing historical data provided by the clinic, the team found that Mondays were the busiest days at the lab, and the longest wait times occurred between 10 a.m. and noon.

Hawthorne said another technique students used was a lean audit, which is used in industry to identify different problem areas within a current system and translate those audits back to identifying waste areas, including excess motion, over processing and transport.

The team presented 10 solution options to Baylor Scott and White. The primary concept involved hiring a patient service specialist at the lab to reduce the amount of time nurses get redirected from their main duties. Another proposed option was to add a TV and text alert system that would allow patients to see their expected wait time and be notified when they can enter the lab.

“Our solutions reduce the average wait time to about 11 minutes for each patient,” Ramos said. “Overall, the top five solutions we presented would help decrease the waiting time and increase patient satisfaction.”

Second place was awarded to Morgan Roberts, Bryana Moya, Joaquin Cieri and Lukas Featherstone, who worked with sponsor Rochester Gauges. Third place was awarded to James Chung, Melanie Beattie, Dhakshin Subbaiah and Lissete Sillas, who worked with sponsor Aggieland Coffee.

Dr. Mike Graul, associate professor of practice, said the students aren’t just given a problem and then left to figure things out on their own. Engineering design is performed systematically, and emphasis is placed on the definition of the requirements and viable solutions driven by those requirements.

“The teams are responsible for a formal, technical argument that spans the entire design process, covering: problem definition, needs analysis, requirements definition, development of alternative solution concepts, analysis of these alternatives, selection and the final design itself,” said Graul, who also served as associate department head for undergraduate affairs in industrial and systems engineering until summer 2022. “The final designs are analyzed with respect to the risk, performance and cost.”

For more information on the department’s capstone program, visit the design website.