Nature’s blueprint for the human limb is a carefully layered structure with stiff bone wrapped in layers of different soft tissue, like muscle and skin, all bound to each other perfectly. Achieving this kind of sophistication using synthetic materials to build biologically inspired robotic parts or multicomponent, complex machines has been an engineering challenge.

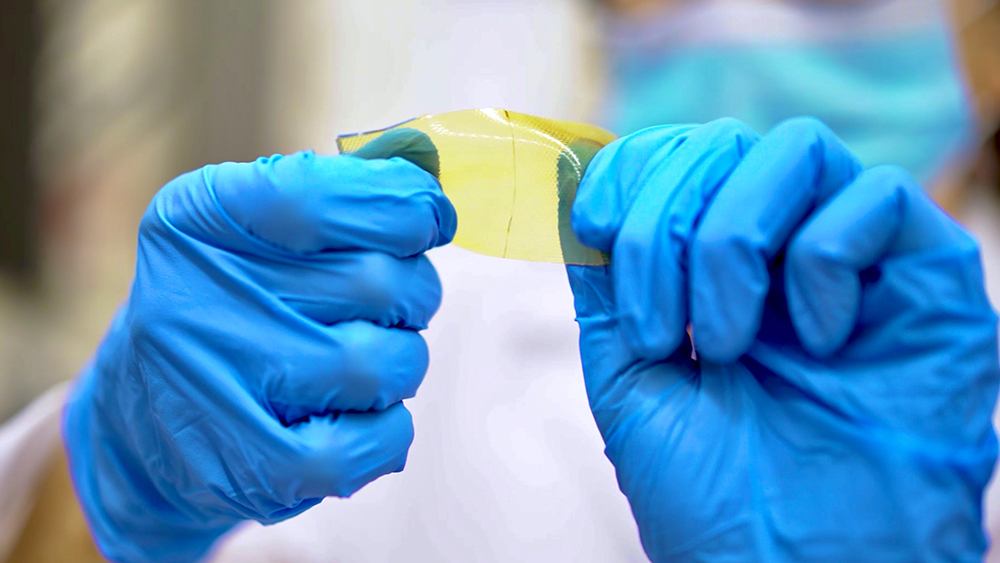

By tweaking the chemistry of a single polymer, researchers at Texas A&M University and the U.S. Army Combat Capabilities Development Command Army Research Laboratory have created a whole family of synthetic materials that range in texture from ultra-soft to extremely rigid. The researchers said their materials are 3D printable, self-healing, recyclable and they naturally adhere to each other in air or underwater.

Their findings are detailed in the May issue of the journal Advanced Functional Materials.

“We have made an exciting group of materials whose properties can be fine-tuned to get either the softness of rubber or the strength of load-bearing plastics,” said Dr. Svetlana Sukhishvili, professor in the Department of Materials Science and Engineering and a corresponding author on the study. “Their other desirable characteristics, like 3D printability and the ability to self-heal within seconds, make them suited for not just more realistic prosthetics and soft robotics, but also ideal for broad military applications such as agile platforms for air vehicles and futuristic self-healing aircraft wings.”

Synthetic polymers are made up of long strings of repeating molecular motifs, like beads on a chain. In elastomeric polymers, or elastomers, these long chains are lightly crosslinked, giving the materials a rubbery quality. However, these crosslinks can also be used to make the elastomers more rigid by increasing the number of crosslinks.

Although previous studies have manipulated the density of crosslinks to make elastomers stiffer, the resulting change in mechanical strength was generally permanent.

“Crosslinks are like stitches in a piece of cloth, the more stitches you have, the stiffer the material gets and vice versa,” said Sukhishvili. “But instead of having these ‘stitches’ be permanent, we wanted to achieve dynamic and reversible crosslinking so that we can create materials that are recyclable.”

So, the researchers focused their attention on the molecules involved in the crosslinking. First, they chose a parent polymer, called prepolymer, and then chemically studded these prepolymer chains with two types of small crosslinking molecules — furan and maleimide. By increasing the number of these molecules in the prepolymer, they found that they could create materials stiffer. In this way, the hardest material they created was 1,000 times stronger than the softest.

However, these crosslinks are also reversible. Furan and maleimide participate in a type of reversible chemical bonding. Put simply, in this reaction, furan and maleimide pairs can “click” and “unclick” depending on temperature. When the temperature is high enough, these molecules come apart from the polymer chains and the materials soften. At room temperature, the materials harden since the molecules quickly click back together, once again forming crosslinks. Thus, if there is any tear in these materials at ambient temperatures, the researchers showed that furan and maleimide automatically re-click, healing the gap within a few seconds.

The researchers noted that the temperatures at which the crosslinkers dissociate or unclick from the prepolymer chains are relatively the same for different stiffness levels. This property is useful for 3D printing with these materials. Regardless of whether they are soft or hard, the materials can be melted at the same temperature and then used as printing ink.

“By modifying the hardware and processing parameters in a standard 3D printer, we were able to use our materials to print complex 3D objects layer by layer,” said Dr. Frank Gardea, research engineer in the United States Army Research Laboratory and a corresponding author on the study. “The unique advantage of our materials is that the layers that make up the 3D part can be of vastly different stiffness.”

As the 3D part cools to room temperature, he added that the different layers join seamlessly, precluding the need for curing or any other chemical processing. Consequently, the 3D-printed parts can easily be melted using high heat and then recycled as printing ink. The researchers also noted that their materials are reprogrammable. In other words, after being set into one shape, they can be made to change into a different shape using just heat.

In the future, the researchers plan to increase the functionality of their new materials by amplifying its multifaceted properties outlined in the current study.

“Right now, we can easily achieve around 80% self-healing at room temperature, but we would like to reach 100%. Also, we want to make our materials responsive to other stimuli other than temperature, like light,” said Gardea. “Further down the road, we’d like to explore introducing some low-level intelligence so that these materials know to autonomously adapt without needing a user to initiate the process.”

Other contributors include Qing Zhou, primary author of the paper, and Zhen Sang from the Department of Materials Science and Engineering; and Dr. Seunghyun Lee and Dr. Matt Pharr from the J. Mike Walker '66 Department of Mechanical Engineering.

This research is funded by the United States Combat Capabilities Development Command Army Research Laboratory.