In the high-octane world of motorsports, a focus on sustainability is pushing Formula 1 and other professional leagues to invest in hybrid technologies to reduce emissions — a level of innovation that is out of reach for smaller leagues. Lacking the deep pockets of their professional counterparts, amateur and pro-am organizations are searching for affordable ways to develop eco-friendly race cars.

With the support of the Sports Car Club of America (SCCA), the largest active motorsports membership organization in the world, a group of Texas A&M University engineering students has stepped up to meet this challenge. The result: an affordable hybrid integration system that allows grassroots racing to respond to environmental accountability without compromising competitiveness.

It all started when amateur driver and manufacturing and mechanical engineering technology student Mark Snyder approached SCCA.

“The idea was to develop a hybrid race car which is fun, affordable and fast in order to show that the lower levels of racing can adapt to ever-changing sustainability demands,” said Snyder.

Under his leadership, a group of 14 engineering students from Aggies Create took on the complex task of creating a cost-effective hybrid integration that solves current systems’ problems of being too costly, large or detrimental to performance.

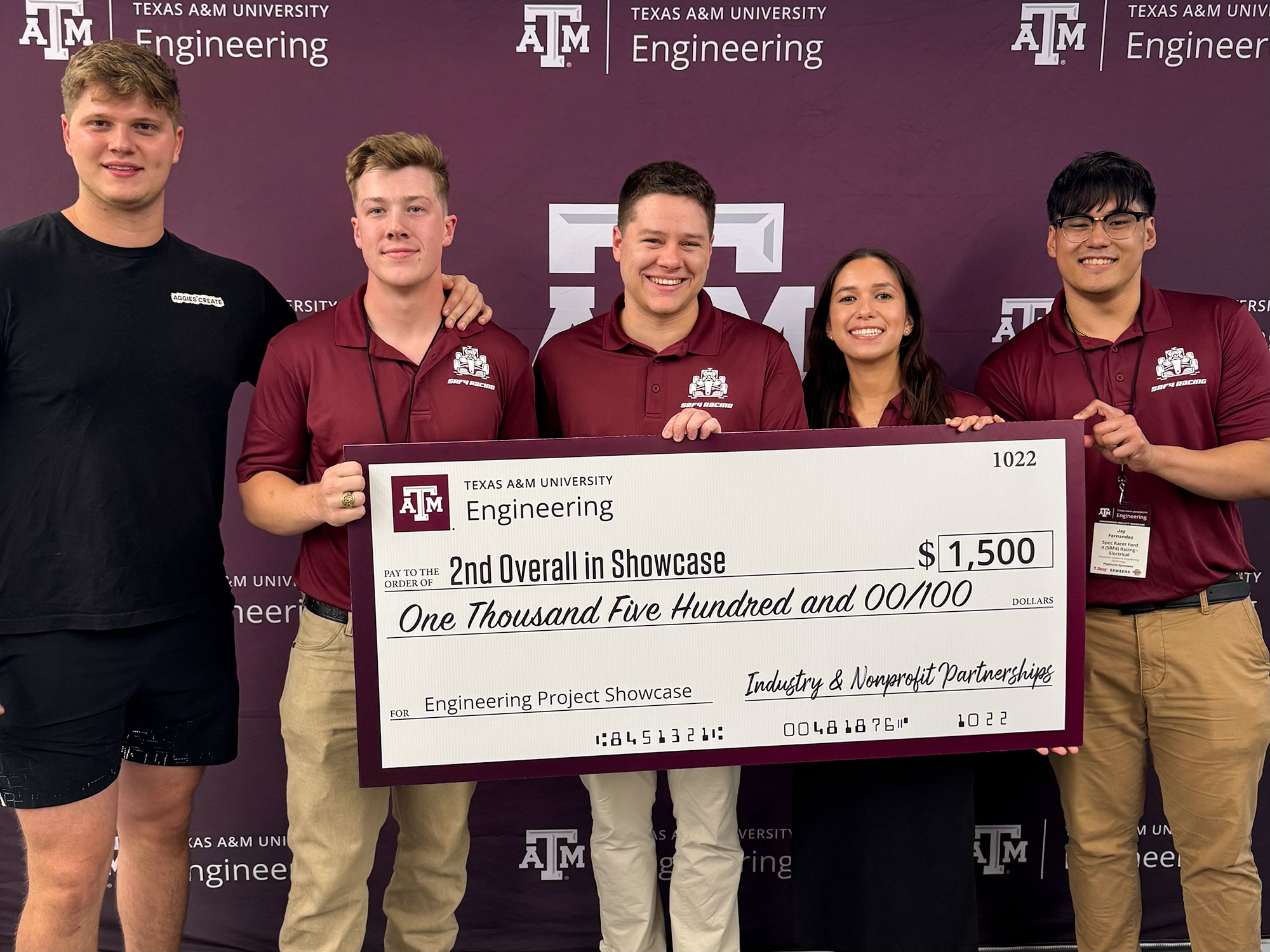

A year into the project, the electronic systems engineering technology (ESET) capstone team of Jacqueline Aleman, Jay Fernandez, Ryan Keener and Henry Waggoner joined the endeavor. With sponsorship by SCCA and technical guidance from ESET’s Dr. Lee Hudson and Dr. Eman Hammad, they developed an electric front wheel drivetrain while the Aggies Create group focused on the car’s rear combustion engine and the physical components of the design.

The key to success was combining the front drive electric system and the rear drive combustion engine. This setup is unique because there are no internal mechanical connections between the front and rear axles.

“It’s called a ‘through-the-road’ hybrid as the two different drive trains are only mechanically connected through the road,” Fernandez explained.

Performance-enhancing elements, such as regenerative braking and a push-to-pass feature, were incorporated into the design. Regenerative braking allows the electric portion of the drivetrain to soak up energy during braking and send it back to the battery. This stored energy is used to boost the combustion engine's power, saving fuel and helping the car accelerate quicker. The push-to-pass feature instantaneously delivers ten seconds of power to the electric motor for up to 200 seconds per race. Keener compared it to “using a mushroom in the Mario Kart video game.”

The team placed a strong emphasis on safety, with extensive hardware testing and software fail-safes to prevent system failures in high-speed environments. They integrated watchdog timers, safe startups, communication fail safes, redundancy checks and a physical kill switch.

The ESET team’s design earned an impressive second-place finish out of 361 at Texas A&M’s 2025 Engineering Capstone Showcase. The group was praised for surpassing the goal of developing a successful prototype by creating a fully functional and competitive electric drive system.

“We are excited to have created a system that reduces carbon emissions while maintaining high performance and the traditional racing experience,” said Aleman. “Additionally, it is designed to be cost-effective for SCCA to manufacture and implement.”

SCCA now has the car in its first prototype stage and hopes to put it on the track by the end of 2025 for baseline analysis. Their goal is mass production and integration in competitive racing.

The Aggie students are proud to have played a part in this effort to safeguard grassroots racing, demonstrating how Texas A&M engineering impacts real-world change.