In high-risk industries, leaders are increasingly turning to automation to make work safer in hazardous environments.

From pandemic preparedness to nuclear waste disposal, national laboratories see the potential of automation to improve worker safety, strengthen operational efficiency and enhance precision. The challenge lies in determining how automated technologies can best achieve these goals while operating in complex, high-stakes environments, like those at Los Alamos National Laboratory (LANL).

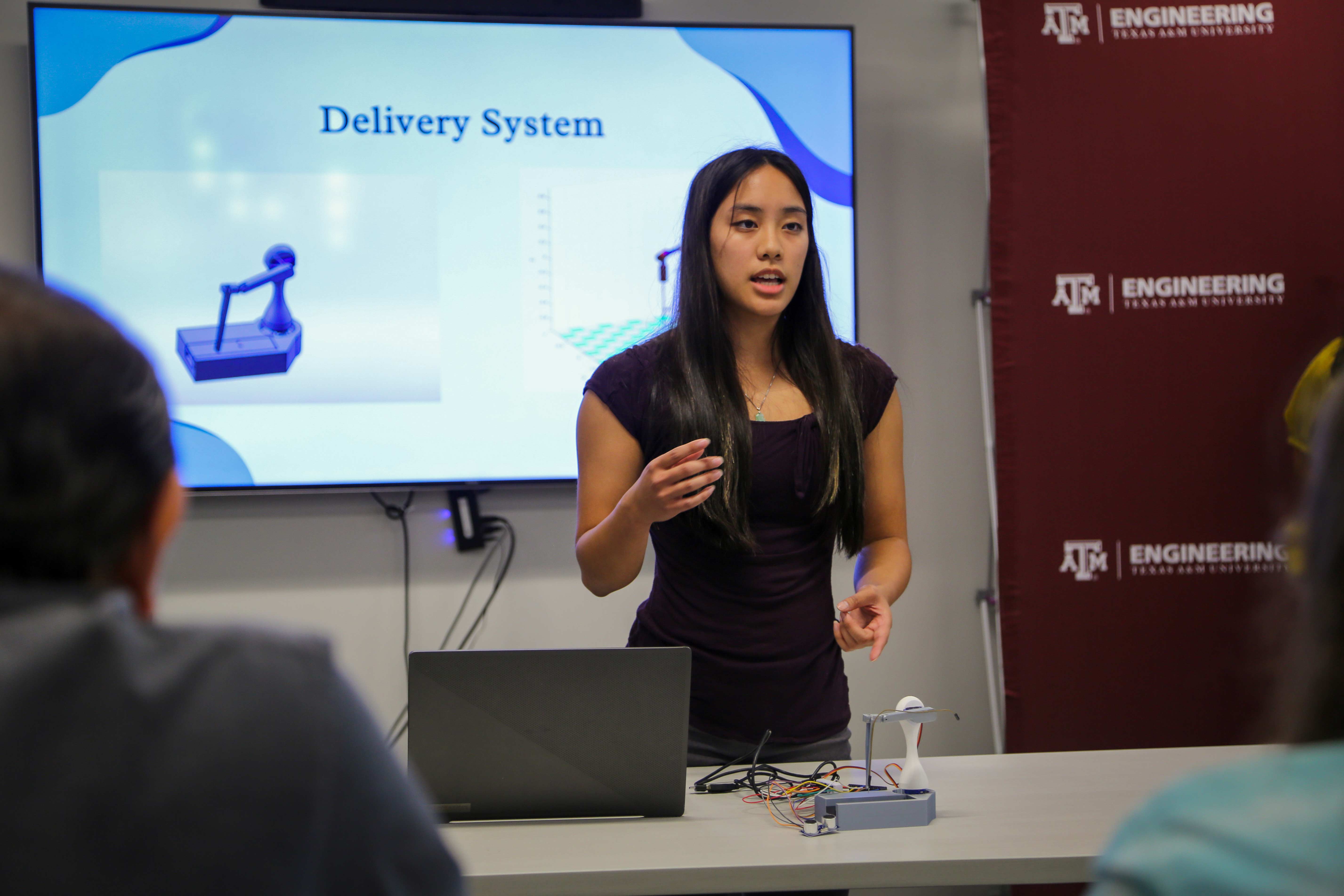

Through its partnership with the College of Engineering, experts from LANL had the opportunity to hear student engineers' visions for the future of robotics at Aggies Invent, a monthly competition hosted by the Meloy Engineering Innovation and Entrepreneurship Program.

Judges from LANL, including R&D Engineer Beth Boardman and TJ Ulrich, Director of University Research and Relations, evaluated 3D-printed and cardboard prototypes crafted by students who were given only 48 hours to create impactful solutions.

“Our technical staff defined the problems around real needs of the laboratory, so the students are getting introduced to very relevant topics and an insight into what is going on at LANL at the moment,” Ulrich explained.

Within two days, 33 students embraced each part of the engineering design process, from customer discovery and research to detailed explanations of functionality and cost analysis.

For LANL, this event is more than a weekend competition — it’s a chance to observe student talent in action. “Events like Aggies Invent allow LANL staff to evaluate students for potential positions better than a regular interview,” Boardman shared. “We can evaluate their critical thinking, teamwork, and technical skill sets.” Each year, talented Aggies are offered internships and invitations to further engage with Los Alamos.

Beyond providing career opportunities, Aggies Invent offers students invaluable mentorship from faculty and industry members, enriching their work in the lab, classroom, and beyond. Working within a tight timeframe and guided by the mentors, students build resourcefulness, refine project management skills, and learn to confidently present emerging ideas, even as they’re still developing a concept.

Jevine Kong, a mechanical engineering junior and member of team FlowSmart, found the experience especially rewarding, noting that “even if you don't place or win an award, you get so much out of it; talking points in interviews, direct contact with and help from well-educated mentors, and a great learning experience.”

FlowSmart's award-winning concept presented a system for pandemic preparedness, featuring a robotic arm, pipette, and high-frequency vibrations to automate the monotonous task of sample sequencing with precision, monitoring efficiency in real-time to reduce human error.

The team not only won first among the LANL judges, but among their peers as well, being named both ‘Most Feasible’ and ‘Best Prototype’ among an audience vote. “I liked that the prototype mimicked the appropriate motion and added value to their presentation,” Boardman remarked.

Awarded second place, NewClear Solutions developed a robotic prototype aimed at transforming nuclear waste disposal. Addressing the risks of traditional glove boxes, their idea features a lead-lined workstation, dual manipulation arms, and a conveyor system. With an estimated $1.2 million budget, the team promises "a new, clear solution" to the current safety hazards of nuclear waste handling.

As LANL representative Ulrich noted on developing solutions for this need, “the outside-the-box ideas are great to see, and we encourage that.”

Team Floprep secured third place with a solution for automating pre-lab processing, crucial for virus tracking. Their prototype uses a robotic arm and conveyor belt to streamline sample preparation, efficiently cutting packaging and transferring samples to the sequencer. The team acknowledged that their innovation lays the groundwork for future biosurveillance automation efforts such as FlowSmart’s, showcasing the collaborative spirit of engineers.

Through its partnership with Texas A&M University and annual sponsorship of events like Aggies Invent, LANL exemplifies its mission to foster tomorrow’s leaders in science and engineering.

“Interacting with students is a great experience,” Ulrich remarked, “and a wonderful reminder of how far we ourselves have come. It’s a pleasure to be able to pass on some of that to the next generation and see them rise to the new challenges we face.”

Whatever the future holds for automation in hazardous environments, it’s likely that LANL — and an Aggie — will be at the forefront.