In a collaborative effort between Texas A&M University and Sandia National Laboratories, researchers have significantly improved a new joining technology, interlocking metasurfaces (ILMs), designed to increase the strength and stability of a structure in comparison to traditional techniques like bolts and adhesives, using shape memory alloys (SMAs). ILMs offer the potential to transform mechanical joint design in manufacturing for aerospace, robotics and biomedical devices.

“ILMs are poised to redefine joining technologies across a range of applications, much like Velcro did decades ago,” said Dr. Ibrahim Karaman, professor and head of the Department of Materials Science and Engineering Department at Texas A&M. “In collaboration with Sandia National Laboratories, the original developers of ILMs, we have engineered and fabricated ILMs from shape memory alloys. Our research demonstrates that these ILMs can be selectively disengaged and re-engaged on demand while maintaining consistent joint strength and structural integrity.”

These findings can be found in Materials & Design.

Similar to Legos or Velcro, ILMs enable the joining of two bodies by transmitting force and constraining movement. Until now, this joining method has been passive, requiring force for engagement.

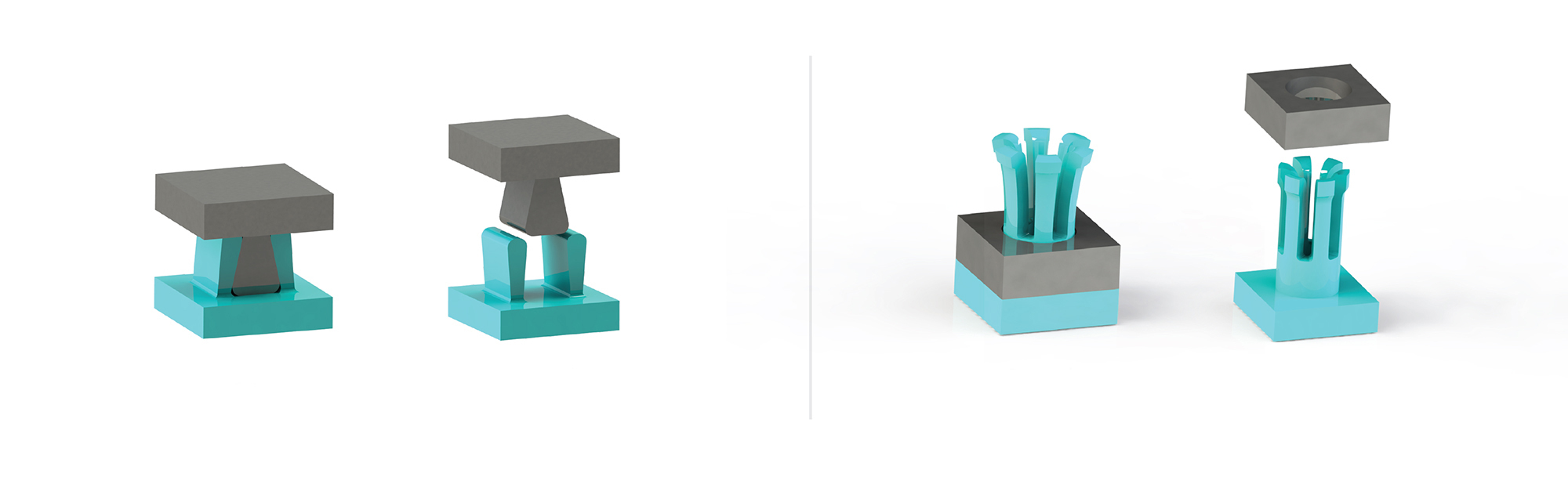

Using 3D printing, the teams designed and fabricated active ILMs by integrating shape memory alloys (SMAs), specifically nickel-titanium, which can recover their original shape after deformation by changing temperatures.

Control of joining technology through temperature changes opens new possibilities for smart, adaptive structures without loss in strength or stability and with increased options for flexibility and functionality.

“Active ILMs have the potential to revolutionize mechanical joint design in industries requiring precise, repeatable assembly and disassembly,” said Abdelrahman Elsayed, graduate research assistant in the materials science and engineering department at Texas A&M.

Practical applications include designing reconfigurable aerospace engineering components where parts must be assembled and disassembled multiple times. Active ILMs could also provide flexible and adaptable joints for robotics-enhancing functionality. In biomedical devices, the ability to adjust implants and prosthetics to body movements and temperatures could offer a better option for patients.

The current findings utilized the shape memory effect of SMAs to recover the ILMs’ shape by adding heat. The researchers hope to build on these findings by using the superelasticity effect of SMAs to create ILMs that can withstand large deformation and instantaneously recover under very high stress levels.

“We anticipate that incorporating SMAs into ILMs will unlock numerous future applications, though several challenges remain,” said Karaman. “Achieving superelasticity in complex 3D-printed ILMs will enable localized control of structural stiffness and facilitate reattachment with high locking forces. Additionally, we expect this technology to address longstanding challenges associated with joining techniques in extreme environments. We are highly enthusiastic about the transformative potential of ILM technology.”

Other contributors include Dr. Alaa Elwany, associate professor in the Wm Michael Barnes ’64 Department of Industrial and Systems Engineering and doctoral student Taresh Guleria in the industrial systems and engineering department.

Funding for this research is administered by the Texas A&M Engineering Experiment Station (TEES), the official research agency for Texas A&M Engineering.