An exciting endeavor to revolutionize the future of how structures will be built is underway in Texas A&M University’s Department of Engineering Technology and Industrial Distribution (ETID). The project explores the system design and mechanics of concrete-printing robots and large-scale additive manufacturing systems to address critical infrastructure and technology challenges.

The major goal of this ongoing work is to enable more effective expeditionary manufacturing technologies that can enhance numerous applications for the United States Army. These include regular military infrastructure support, disaster relief efforts, space exploration, and the construction and maintenance of remote research stations. On the civilian front, the technology may be applied in construction, civil infrastructure, and agricultural technology.

The project is in partnership with the Autonomous Construction and Manufacturing at Scale lab led by founding director and distinguished robotics researcher Dr. William R. Norris at the University of Illinois at Urbana-Champaign and funded by the U.S. Army Corp of Engineers’ Engineering Research and Development Center Construction Engineering Research Laboratory.

“Autonomous System and Architecture for Construction-Scale Additive Manufacturing,” Texas A&M’s first phase of the multi-stage collaboration, focuses on the development of systems engineering architecture and the design of robotic systems, including stable platforms and printing arms for small robot teams. The project is expected to move into phase two within 9-12 months.

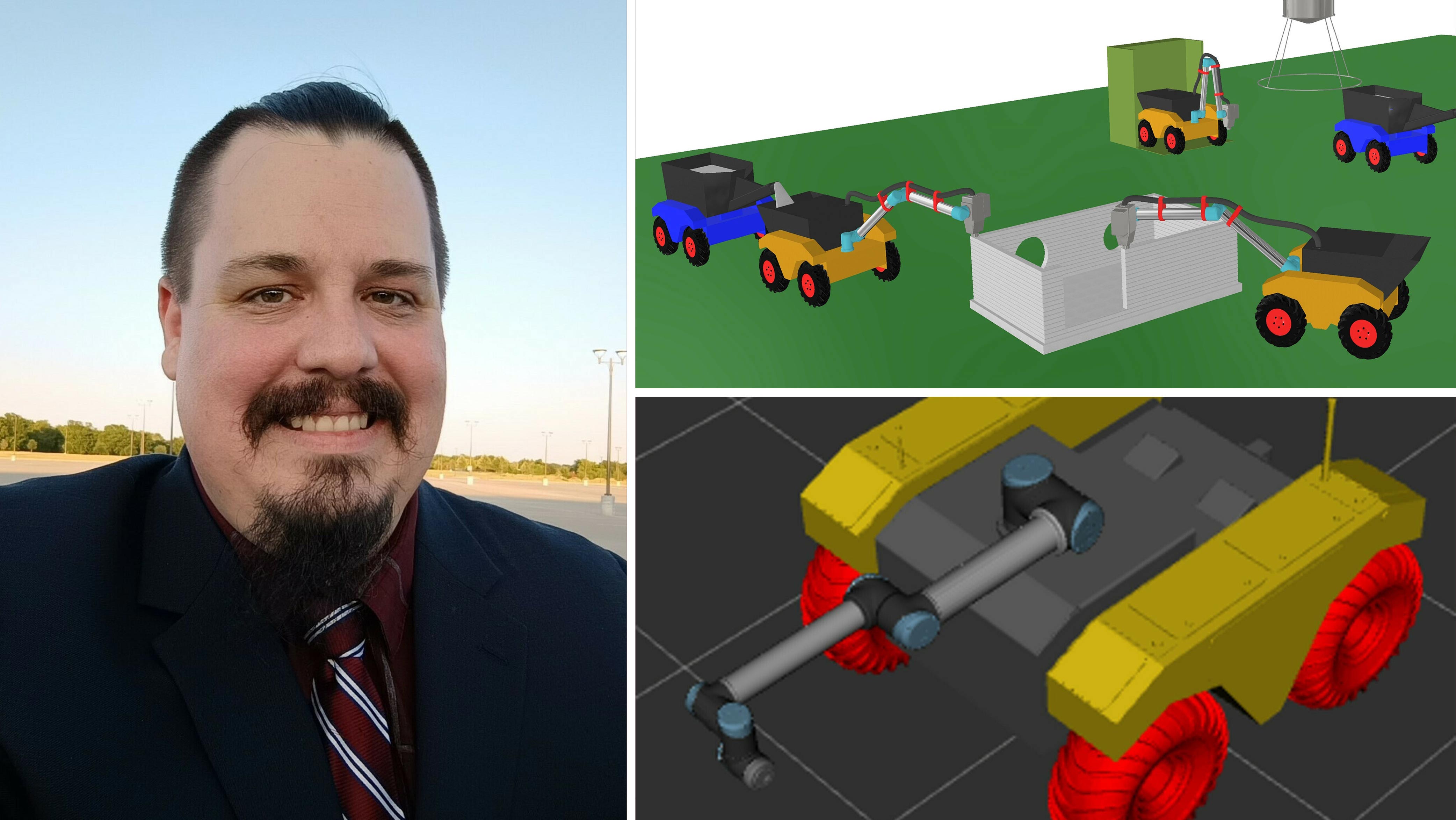

ETID Assistant Professor Dr. Albert E. Patterson serves as the project’s principal investigator for Texas A&M and is the director of the Manufacturability-Driven Design Lab where the work is based. He explains the significance of the research: “We are combining systems engineering practice and theory, additive manufacturing, modeling, and simulation and field trials using various types of common ground vehicles. This project will help to translate our recent research progress in the manufacturing and robotic systems domains into useful real-world systems which will increase the reliability and safety of automated construction, enabling its wider use.”

Two academic papers outlining the initial progress will be published in 2024. They have been accepted to the Design for Manufacturing and the Life Cycle Engineering (DFMLC) section of the 2024 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (IDETC/CIE), which is hosted by the American Society of Mechanical Engineers.