Hosted by the Meloy Engineering Innovation and Entrepreneurship Program, Aggies Invent: Para Athlete was held simultaneously with the World Cup 2024 Olympic Qualifying Para-Cycling event hosted by the city of Bryan and Texas A&M University.

In just 48 hours, 48 engineering students developed adaptive technologies, prosthetics and equipment to allow future para-athletes to more effectively compete and further demonstrate human perseverance in sports.

Many students took the initiative to conduct first-person interviews, gaining valuable personal accounts of the diverse needs of parathletes.

Reid Miles, a biomedical engineering student and member of the first-place team Victory L.A.P., recognizes the significance of engaging in open conversation with the communities their engineering innovations aim to support.

“We had the opportunity to gain insight from para-cyclists to better understand their struggles with the current technology,” said Miles. “Because of this, we were able to focus on solving a significant problem that impacts many para-athletes today.”

Team Victory L.A.P. (Leading Adaptive Prosthetics) received first place with their novel prosthetic leg sleeve design to enhance performance for para-cyclists, winning a $5,000 prize and para-cycling merchandise to commemorate the event.

“From our interviews, we identified that sweat is a major issue in the prosthetic socket, causing discomfort and impacting performance in many ways,” Miles explained.

“Our team developed a sleeve design that funnels air into an open layer in the sleeve during the cyclist's motion. This layer contains heat pins and a thermally conductive fabric to dissipate heat from the socket, cooling the skin and ultimately reducing sweating,” said Miles.

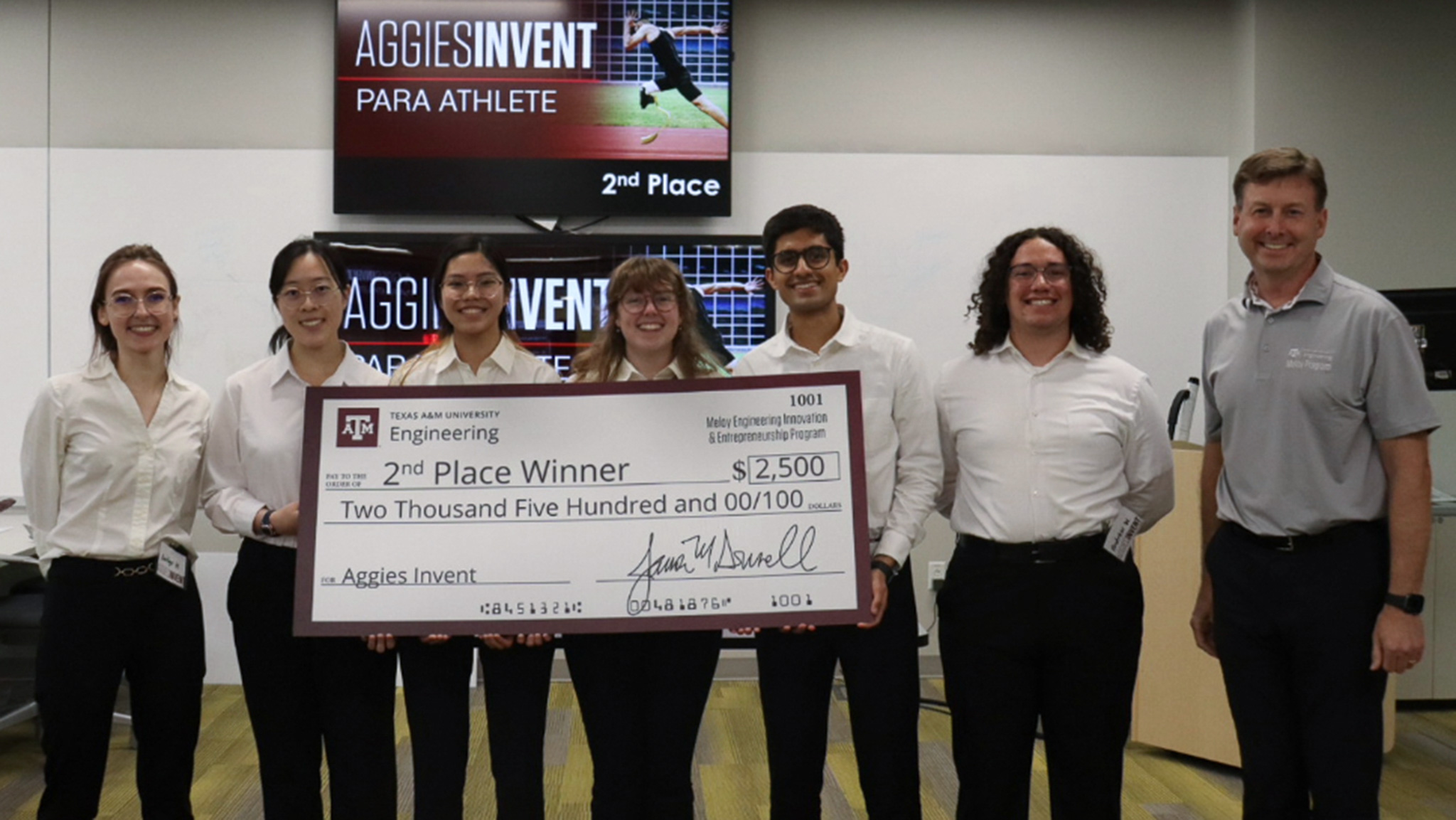

The second-place team, ParaMount, devised an innovative bicycle technology for adaptive athletes featuring separate gears for each leg, addressing common struggles in strength imbalances and weight distribution. The design enables para-cyclists to leverage their weaker leg when necessary and allow it to remain idle when not in use.

While the team was able to confidently display their working prototype, they stressed that the success they found was not without challenges.

“We had to completely scrap our idea in the middle of the day prior to presentations, so it was very difficult to try and catch up with the rest of the teams and complete the design process,” said Kaitlyn Hawkins, a sophomore in mechanical engineering.

“It's a great feeling to know that we definitely got there in the end. It was just very engaging to sit and bounce ideas off of each other, all working together towards a common goal,” Hawkins said.

Team Too Cool earned third place for developing a wearable thermoelectric device that would serve to cool the wrists and ankles of a para-athlete. Their research found that regulating body temperature during training and competition enhances comfort, prevents injuries and optimizes performance outcomes.

At the core of each Aggies Invent is the opportunity for students to reflect on the process of researching, designing, and presenting on their work.

Aerospace engineering student Ansh Panchal discovered that navigating the collaborative decision-making process amidst a plethora of ideas proved to be both the most challenging and the most engaging aspect of the experience.

“Normally, for engineers, we find solutions immediately and find data to back up our claims,” explained Panchal. “It was a much more challenging experience to find different alternatives than what you thought of initially to come to a successful prototype. Overall, our team worked really well together.”