Under the Defense University Research Instrumentation Program, Dr. Patrick Shamberger and a research team from the Department of Materials Science and Engineering received a grant from the U.S. Department of Defense (DOD) to acquire instrumentation for thermal energy storage research.

The grant, administered through the Office of Naval Research, will support the acquisition of a high-sensitivity multi-modal calorimeter for advanced research and education on tunable energy storage materials. This equipment will allow cutting-edge research to study the capability of pressure and humidity to control how well these materials can store thermal energy.

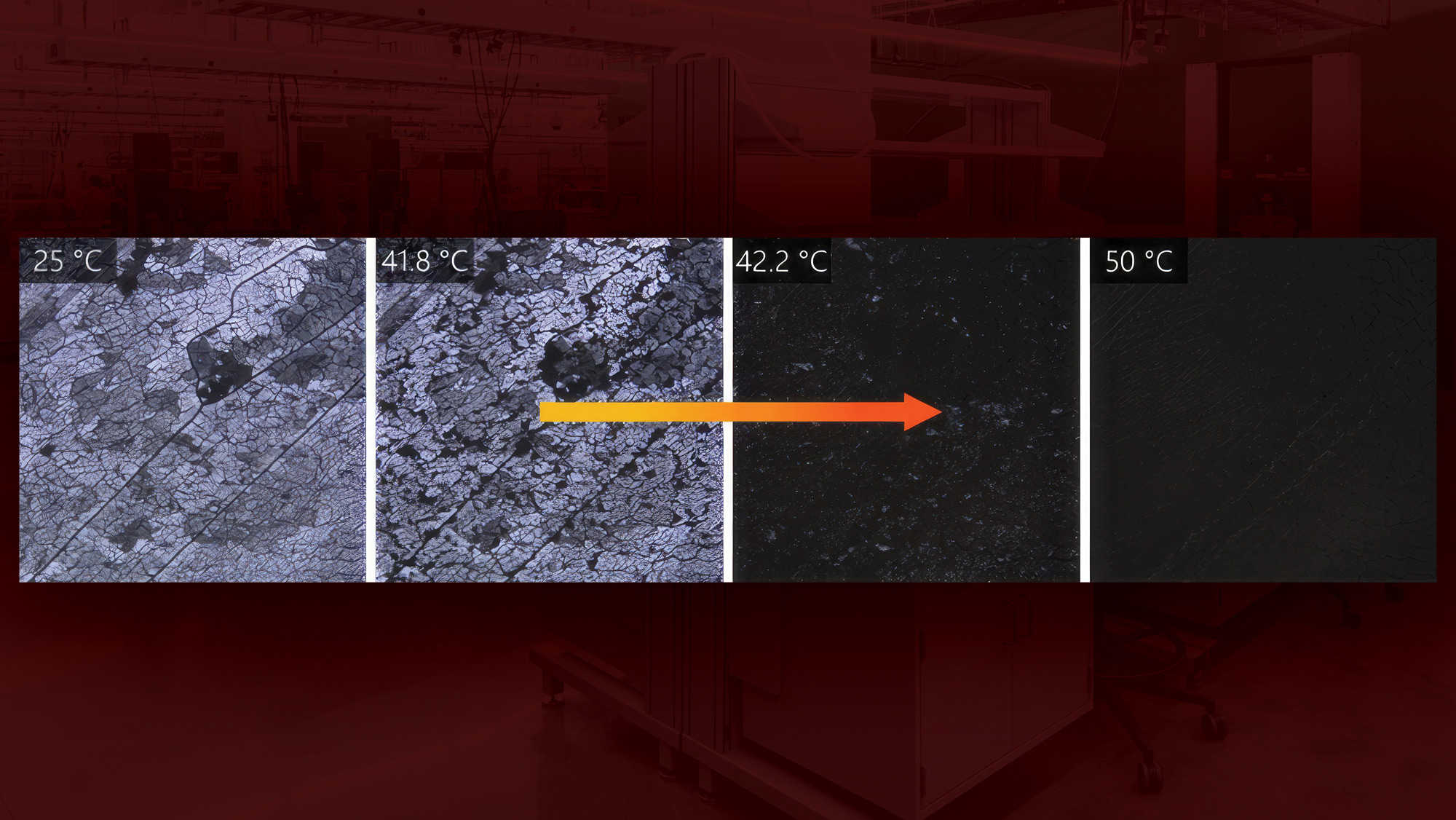

Advancements in system power density have led to lighter and smaller components, but they've also brought about significant challenges in managing heat. To handle thermal loads efficiently without oversizing components like pumps and heat exchangers, there's a growing focus on dynamic thermal properties and components. This includes exploring tunable thermal conductivity, switches, diodes, rectifiers, and emissivity. However, there's a critical gap in understanding regarding materials with dynamically tunable heat capacity or latent heat storage effects.

The newly awarded instrumentation system stands out as an exceptional calorimetry system. It promises unparalleled sensitivity and adaptability, enabling material analysis across a wide temperature range (minus 120 to 830 degrees Celsius), various pressures, humidity levels (up to 90% at 70 degrees Celsius), and diverse carrier gases, encompassing both adsorptive (carbon dioxide, water vapor) and reactive gases (like hydrogen).

This system is poised to serve as the cornerstone for developing groundbreaking adaptive materials that align with the needs of the DOD in the next decade. It will especially aid in creating dynamically tunable phase change materials. Additionally, this system opens doors for a range of fundamental research programs. It fosters the training of a skilled workforce ready to engage in research and development activities essential for the defense sector's advancements.

Members of the team include Drs. Ibrahim Karaman, Raymundo Arroyave, Emily Pentzer and Svetlana Sukhishvili from the Department of Materials Science and Engineering at Texas A&M University, and Dr. Neera Jain from the School of Mechanical Engineering at Purdue University.