A team of mechanical engineering students partnered with Stratasys Direct Manufacturing to design and produce a build plate transfer system to assist operators in safely and efficiently removing 3D-printed metal parts — weighing up to 200 lbs — from their machines.

The company sponsored the team’s senior capstone design program project, a part of the curriculum for seniors in the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M University.

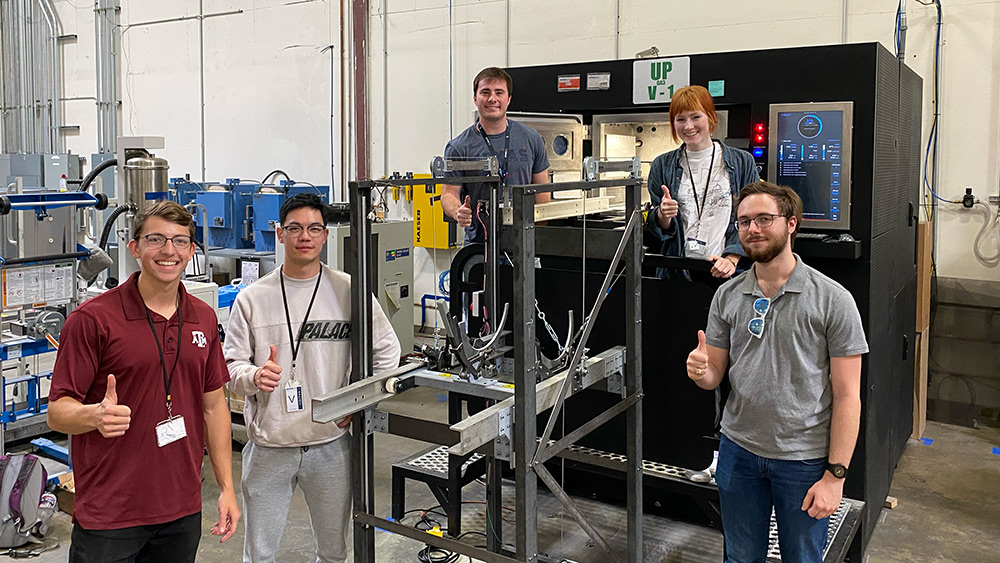

The team included Erin Carter, Jake Ford, Brandon Sheneman, David Wang and Michael Zanoff. The team’s industry liaison for the project was Joel Sam, a class of ‘16 graduate from the department and a current employee of Stratasys Direct Manufacturing.

Sam said the students came into the project eager to learn and never shied away from asking questions when more information was needed to support their design process, demonstrating a level of excellence through their work that he and his employers highly valued.

“The students demonstrated an exceptional level of skill in mechanical design, project management, conceptualization and fabrication,” he said. “This team was able to deliver a fully functional final product that meets all requirements in the problem statement. This system will be implemented on our manufacturing floor for use in production on a weekly basis, at minimum. The level of craftsmanship on the final product was very impressive.”

Team members shared their thoughts on their experience working on the project and its impact on them.

Q: What interested you in this project?

A: Michael Zanoff - My favorite aspect of engineering is the process of going from an initial concept to a reality. This project provided the unique opportunity to develop an end-use product capable of completing a very specific task, which piqued my interest.

Q: What was the biggest challenge the team faced?

A: Erin Carter - Since our project required several distinct functions, we split it into subsystems. This simplified the design process but posed challenges regarding communication and interfacing. All design adjustments had to be documented well and shared within the team to ensure small mistakes and misalignments didn’t propagate.

Q: What were the most important lessons learned working on this project?

A: Michael Zanoff - When working as a team, it is essential that each member contributes to the project as a whole. Throughout this project, I learned how to manage and encourage team members to meet various deadlines and deliverables. Communication and execution are critical to the success of any and every project.

Q: What are you most proud of with this project?

A: Jake Ford - It is incredibly satisfying to produce a well-working product that our sponsor will be able to utilize every day to improve production and alleviate strain on the workers. Designing and manufacturing a product that the sponsor will utilize helps verify this year-long project’s importance and purpose.

Q: How do you think the capstone program will prepare you for the future?

A: Erin Carter - The mechanical engineering program at Texas A&M does a great job teaching us the fundamentals and theory of our discipline, but hands-on experiences are limited. The capstone program ensures every student performs the entire design process, from ideation to implementation, before they graduate.