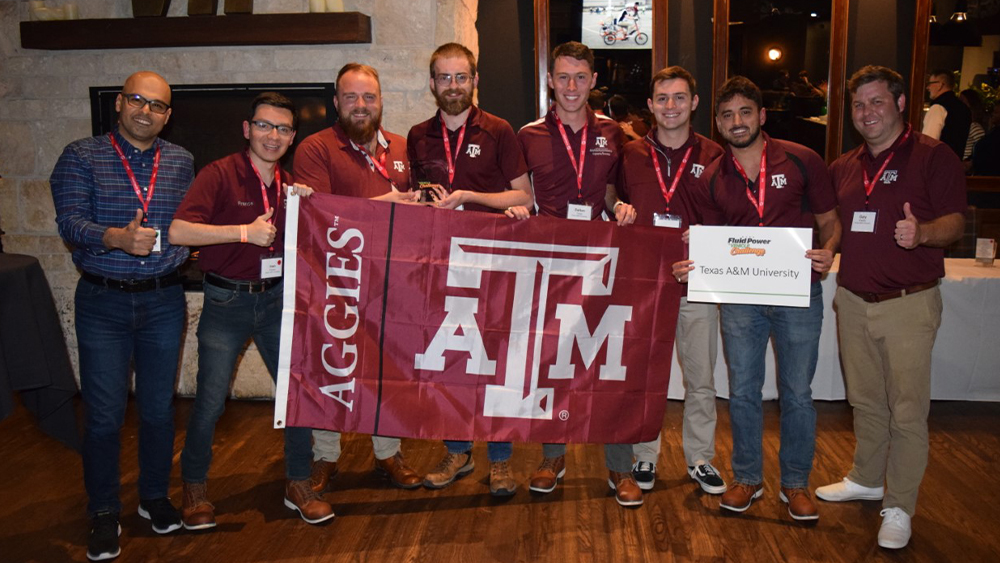

The brilliant minds behind the TAMU Fluid Power Club include members (from top left) Mark Finley, Preston Baumgartner, Dalton Yingst, Aquiles Alonso, Ivan Franco and David Johnson. |

Image: Courtesy of Dr. Ahmed Abdelaal.

Students from the Department of Engineering Technology and Industrial Distribution made history at Texas A&M University, winning first place in the annual Fluid Power Vehicle Challenge competition hosted by the National Fluid Power Association (NFPA) in Littleton, Colorado. The team's fluid-powered bicycle, which utilized a hydraulic circuit instead of a chain to transfer power from the rider to the wheels, outshined 11 other finalist schools.

The team members — all TAMU Fluid Power Club officers — included Ivan Franco, Aquiles Alonso, Mark Finley, Dalton Yingst, Preston Baumgartner and David Johnson, with each member playing a crucial role. Alonso and Franco led the electronics and software team; Johnson and Finley were responsible for mechanical design, with Finley also serving as the project manager and TAMU Fluid Power Club president; and Baumgartner and Yingst led the hydraulic design, with Yingst serving as financial manager of the team and as treasurer of the club.

The competition attracted universities from across the country, including Purdue University, the University of Cincinnati and The University of Akron, and required teams to design and build a fluid-powered vehicle capable of performing in various capacities.

The Texas A&M team's exceptional technical and soft skills impressed the NFPA officers and organizers, as well as the judges, who hailed from top-tier companies in fluid power, such as SunSource, Iowa Fluid Power (IFP) Motion Solutions Inc. and Norgen.

The team's success resulted from a collaborative effort by faculty, staff and students. Dr. Ahmed Abdelaal, an instructional assistant professor in the engineering technology and industrial distribution department, was the team advisor and provided valuable guidance. Senior lecturer Gary Bradley and the capstone instructor for the Manufacturing and Mechanical Engineering Technology program also played crucial roles in the team's success. Chris Smith, Kyle Kuehl and Scott Butler provided technical expertise essential to the team's victory, such as the use of a water jet and the welding aspects of the project, which helped the team earn their victory. Others from outside the department included Brian Tritle from IFP Motion Solutions, who was the industry mentor for the team, and Ernie Parker, of the Fluid Power Hall of Fame, who offered his guidance to all the teams in the competition. The team also had support from many others behind the scenes, including Kristi Dodsen, Makenzie Edwards, Alex Merritt and Pam Spangle.

“The team would like to thank the NFPA, including Mary Pluta, Stephanie Scaccianoce, Kyla Olson and Elexus Comyne, for the support that they provide to be part of this competition,” Finley said.

The team members — all TAMU Fluid Power Club officers — included Ivan Franco, Aquiles Alonso, Mark Finley, Dalton Yingst, Preston Baumgartner and David Johnson, with each member playing a crucial role. Alonso and Franco led the electronics and software team; Johnson and Finley were responsible for mechanical design, with Finley also serving as the project manager and TAMU Fluid Power Club president; and Baumgartner and Yingst led the hydraulic design, with Yingst serving as financial manager of the team and as treasurer of the club.

The competition attracted universities from across the country, including Purdue University, the University of Cincinnati and The University of Akron, and required teams to design and build a fluid-powered vehicle capable of performing in various capacities.

The Texas A&M team's exceptional technical and soft skills impressed the NFPA officers and organizers, as well as the judges, who hailed from top-tier companies in fluid power, such as SunSource, Iowa Fluid Power (IFP) Motion Solutions Inc. and Norgen.

The team's success resulted from a collaborative effort by faculty, staff and students. Dr. Ahmed Abdelaal, an instructional assistant professor in the engineering technology and industrial distribution department, was the team advisor and provided valuable guidance. Senior lecturer Gary Bradley and the capstone instructor for the Manufacturing and Mechanical Engineering Technology program also played crucial roles in the team's success. Chris Smith, Kyle Kuehl and Scott Butler provided technical expertise essential to the team's victory, such as the use of a water jet and the welding aspects of the project, which helped the team earn their victory. Others from outside the department included Brian Tritle from IFP Motion Solutions, who was the industry mentor for the team, and Ernie Parker, of the Fluid Power Hall of Fame, who offered his guidance to all the teams in the competition. The team also had support from many others behind the scenes, including Kristi Dodsen, Makenzie Edwards, Alex Merritt and Pam Spangle.

“The team would like to thank the NFPA, including Mary Pluta, Stephanie Scaccianoce, Kyla Olson and Elexus Comyne, for the support that they provide to be part of this competition,” Finley said.

The team took fluid power to new heights with their trailblazing design. |

Image: Courtesy of the NFPA.

“The NFPA allows students to apply their academic knowledge to real-world applications through the Fluid Power Vehicle Challenge,” Abdelaal said. “The challenge allows students to design and build a working vehicle using the knowledge they gain from classes offered in the engineering technology and industrial distribution department. It was a great experience for the team, and they did a fantastic job, with a special thanks to Bradley, who helped with the team's mechanical design and project management aspects.”

The Texas A&M team had to compete in four races to win first place. The sprint race tested speed, the endurance race tested distance, the efficiency race tested the bike’s efficiency, and the regeneration race involved storing energy while in motion. The winner was determined by considering the midway and final presentations, industry mentor meetings and the four races.

For their achievements, the team earned a total of $4,000. Of the total cash prize, $2,000 will be used for next year’s engineering technology and industrial distribution department capstone program, and the other $2,000 will be split between the team members.

Yingst said, “We went into the competition as the underdogs, with this year being only the second time Texas A&M has competed. And having access to resources like the Bosch Rexroth-R.C. Womack Fluid Power Laboratory in Thompson Hall helped us a ton with the hydraulic design. We could go in there and then set up our hydraulic design and see how it would work. You can plug in your real-world hose diameters and pump throughputs. Having access to those and working on it through the computer and not just having to write everything down by hand was a huge help to this project.”

“We offer unique classes that gave the students some principles to be able to compete in this challenge,” Bradley said, highlighting the advanced welding and fluid power courses and fluid mechanics course with the application of industrial systems for power applications.

Finley added, “Professor Matthew Whiteacre’s courses allowed us to build a strong foundation of knowledge to design our bike in Fusion 360, a computer-aided design software, so we can see it before we actually have our parts.”

The Texas A&M team had to compete in four races to win first place. The sprint race tested speed, the endurance race tested distance, the efficiency race tested the bike’s efficiency, and the regeneration race involved storing energy while in motion. The winner was determined by considering the midway and final presentations, industry mentor meetings and the four races.

For their achievements, the team earned a total of $4,000. Of the total cash prize, $2,000 will be used for next year’s engineering technology and industrial distribution department capstone program, and the other $2,000 will be split between the team members.

Yingst said, “We went into the competition as the underdogs, with this year being only the second time Texas A&M has competed. And having access to resources like the Bosch Rexroth-R.C. Womack Fluid Power Laboratory in Thompson Hall helped us a ton with the hydraulic design. We could go in there and then set up our hydraulic design and see how it would work. You can plug in your real-world hose diameters and pump throughputs. Having access to those and working on it through the computer and not just having to write everything down by hand was a huge help to this project.”

“We offer unique classes that gave the students some principles to be able to compete in this challenge,” Bradley said, highlighting the advanced welding and fluid power courses and fluid mechanics course with the application of industrial systems for power applications.

Finley added, “Professor Matthew Whiteacre’s courses allowed us to build a strong foundation of knowledge to design our bike in Fusion 360, a computer-aided design software, so we can see it before we actually have our parts.”

A team of Aggies claimed the gold in Fluid Power Vehicle Challenge. |

Image: Courtesy of the NFPA.

“Here in the engineering technology and industrial distribution department, we’re ready to compete,” Baumgartner said. “And we’re able to compete at a high level with other nationally recognized engineering schools, and not just with their engineering technology departments, but with their mechanical engineering departments too, by showcasing that we have a good foundation that we learned from the engineering technology and industrial distribution department. We are willing to come together and work on projects like these with as much passion as we did, and we’re proud of the growth we’ve achieved through this department.”

Finley credits his participation in the competition with helping him develop valuable project management, leadership and communication skills. He said that the students’ presentations in the capstone class prepared him for real-world situations. And although the team ran into a handful of complications and setbacks, overall, they worked together to overcome the challenges, make history for Texas A&M and the engineering technology and industrial distribution department, and begin a legacy for the TAMU Fluid Power Club.

The team's NFPA Fluid Power Vehicle Challenge success has been a personal achievement and a stepping stone for the TAMU Fluid Power Club’s future success. The club’s founding members, with their advisor, Abdelaal, are determined to bring underclassmen into the fold for future semesters. “We want to make sure we have a club constantly bringing in new students and new ideas so we can keep competing and growing as a team,” Finley said. The club aims to provide hands-on experience for students interested in fluid power and engineering, encouraging them to participate in future competitions and to apply their skills in real-world applications.

The victory brought great pride to Texas A&M and highlighted the exceptional talent and dedication of the students and faculty in the engineering technology and industrial distribution department. The team set a high bar for itself and other schools, and it looks forward to defending its title in the next Fluid Power Vehicle Challenge.

Those interested in competing in the Fluid Power Vehicle Challenge or learning more about the TAMU Fluid Power Club are encouraged to contact Abdelaal for further information.

Finley credits his participation in the competition with helping him develop valuable project management, leadership and communication skills. He said that the students’ presentations in the capstone class prepared him for real-world situations. And although the team ran into a handful of complications and setbacks, overall, they worked together to overcome the challenges, make history for Texas A&M and the engineering technology and industrial distribution department, and begin a legacy for the TAMU Fluid Power Club.

The team's NFPA Fluid Power Vehicle Challenge success has been a personal achievement and a stepping stone for the TAMU Fluid Power Club’s future success. The club’s founding members, with their advisor, Abdelaal, are determined to bring underclassmen into the fold for future semesters. “We want to make sure we have a club constantly bringing in new students and new ideas so we can keep competing and growing as a team,” Finley said. The club aims to provide hands-on experience for students interested in fluid power and engineering, encouraging them to participate in future competitions and to apply their skills in real-world applications.

The victory brought great pride to Texas A&M and highlighted the exceptional talent and dedication of the students and faculty in the engineering technology and industrial distribution department. The team set a high bar for itself and other schools, and it looks forward to defending its title in the next Fluid Power Vehicle Challenge.

Those interested in competing in the Fluid Power Vehicle Challenge or learning more about the TAMU Fluid Power Club are encouraged to contact Abdelaal for further information.