Five Texas A&M University students enjoyed the opportunity to give back to the local community by designing new mechanics for and creating new schematics of a famous feature in downtown Bryan, Texas.

Mitch Fauber, Aaron Ildefonso, Daniel Mayoral, Sneha Sequeira and Cara Sutter, undergraduate students in the J. Mike Walker ’66 Department of Mechanical Engineering, were tasked with a Capstone project to redesign the interior mechanics of the rotating crown atop the Queen Theatre using a system that will function long term. They were also asked to produce an accurate set of shop drawings for fully replicating the building’s regal topknot, should it ever need to be recreated.

The students took time to sit down and discuss the project, funded by the Downtown Bryan Association (DBA).

“What drew me to this project was the opportunity to work with people in our community and directly impact the beautiful and iconic area of downtown Bryan,” Sutter said.

“The most important lesson we learned was being able to adapt to the changes that came up,” said Mayoral. “Originally, we thought we would fully redesign the crown itself.”

As part of the Queen’s renovation in the 2010s, the rotating crown on the parapet wall of the art deco-style building was temporarily removed and restored with new paint and neon lighting by a local business. While the new lighting continues to function properly, the 80-year-old drive and motor system that rotates the crown still needed help.

“The Queen Theatre crown is an iconic landmark with great sentimental value,” said Sequeira. “However, its rotational mechanism often malfunctions, and the crown lacks any original drawings.”

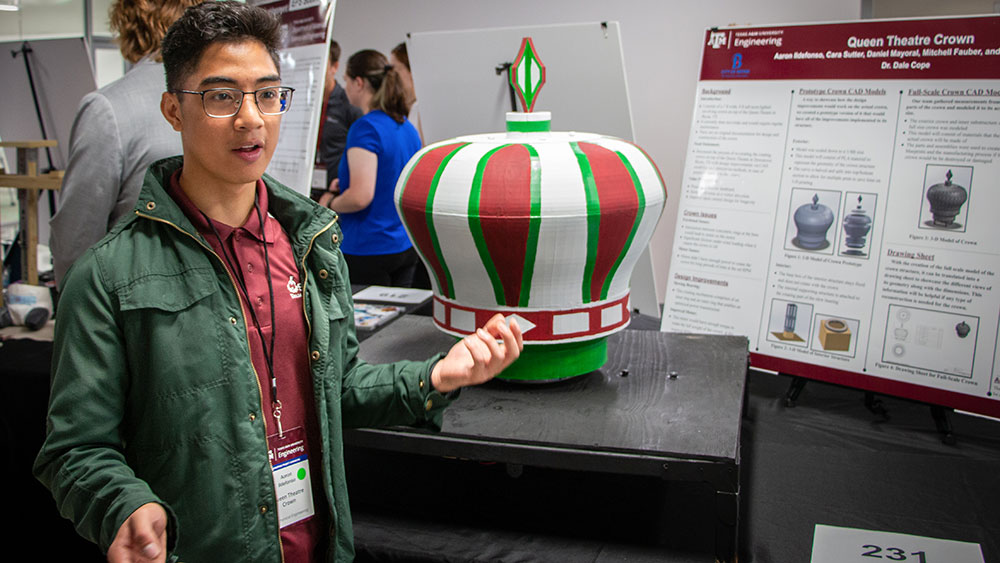

“The project has two parts,” Fauber said. “The first is creating a set of 3D computer-aided design (CAD) models of the full-scale crown accompanied by drawings that include its critical dimensions. The second is redesigning the rotational mechanism that turns the crown, along with a cost model. The proposed design changes will be shown in the prototype the team is currently fabricating.”

“Our main challenge has been taking accurate measurements of the crown,” Sequeira said. “Since it’s directly connected to the roof and cannot be removed, it’s difficult to access certain areas, and the team had to make do with estimations. However, we enjoyed taking measurements and photos for the CAD modeling.”

“This project implied that SOLIDWORKS CAD software would be heavily involved in modeling the crown,” said Ildefonso. “This proved to be very true.”

“The most surprising element has been the design of the crown itself,” Sutter said. “We were able to visit the Queen Theatre and see the crown up close several times, and each time we learned more about how this unique landmark was constructed.”

The historic building was originally a hotel built in the late 1800s. The hotel management began showing silent films on the ground level in the early 1900s. In 1914, the hotel was officially named “Queen Theatre.” It was converted into a fully operational movie theater in 1939. From that time to the mid-1970s, it was operated by the Schulman family, who also operated other local movie theaters.

The DBA purchased the building in 2010 and reopened it in 2018 as a single-screen film house and performance venue. The theater is now run by a company owned by the same Schulman family. Additional modifications have been made so the Queen can feature first-run movies and other premiere events.

“I think the part that makes us the proudest is that we are able to help the city of Bryan with something that holds such historical significance,” said Mayoral. “Being part of the city’s history is something not a lot of engineers can say and is something we will cherish forever.”

“We would like to thank our sponsors for giving us this opportunity,” Fauber said. “We look forward to delivering the final products to them.”

A representative for the City of Bryan, deputy city manager Joseph Dunn, also took time to comment on the project.

"It was a privilege to work with a top-notch team of engineering students in developing a viable long-term mechanical solution to enhance one of Bryan’s most iconic downtown buildings," Dunn said.