Humans and robots may be sharing some of the same goals and manufacturing spaces soon as autonomy and robot technology continue to advance.

Researchers at Texas A&M University are analyzing how this dynamic duo can work in unison to allow for one party to step up where the other may temporarily lack.

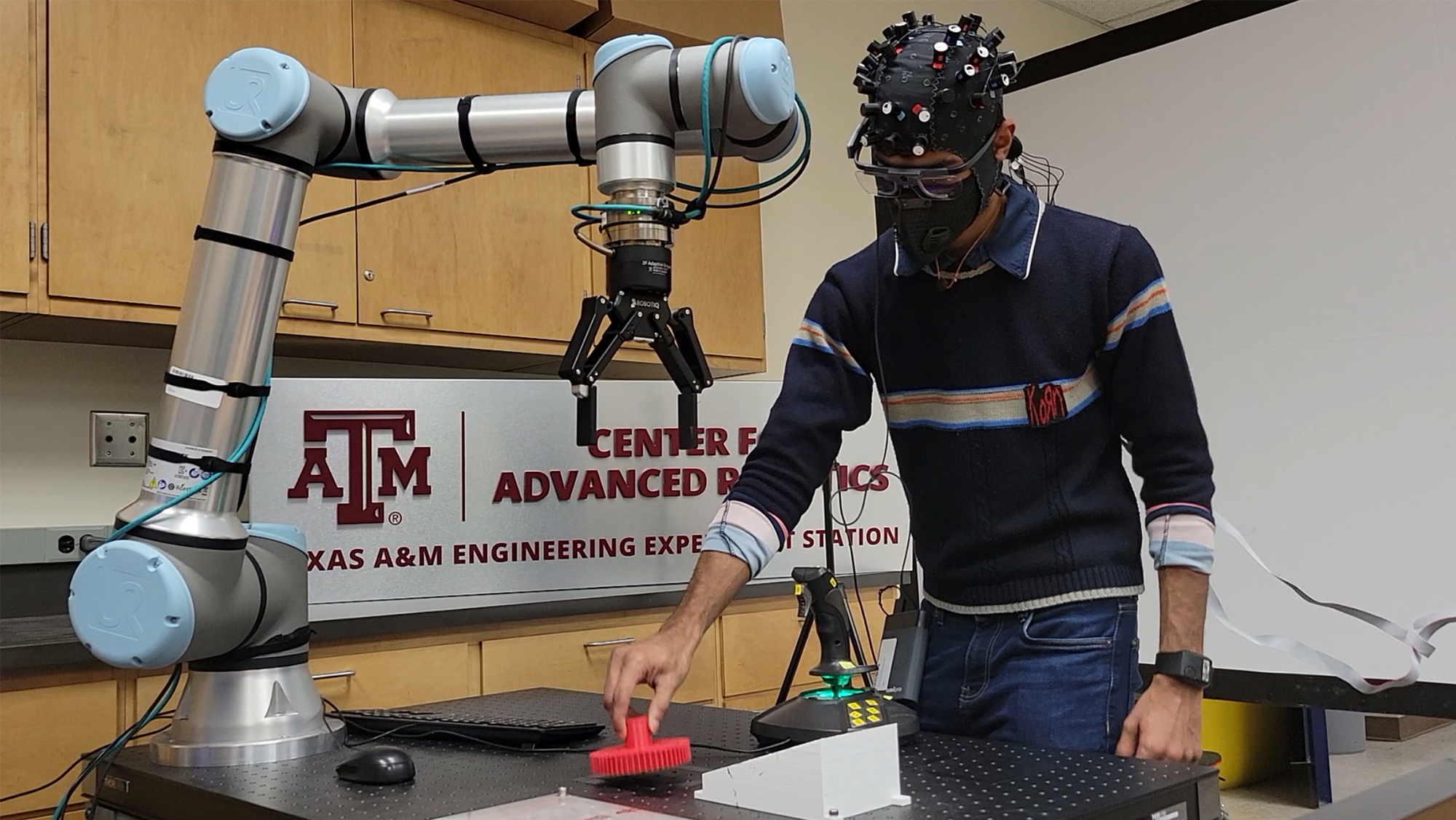

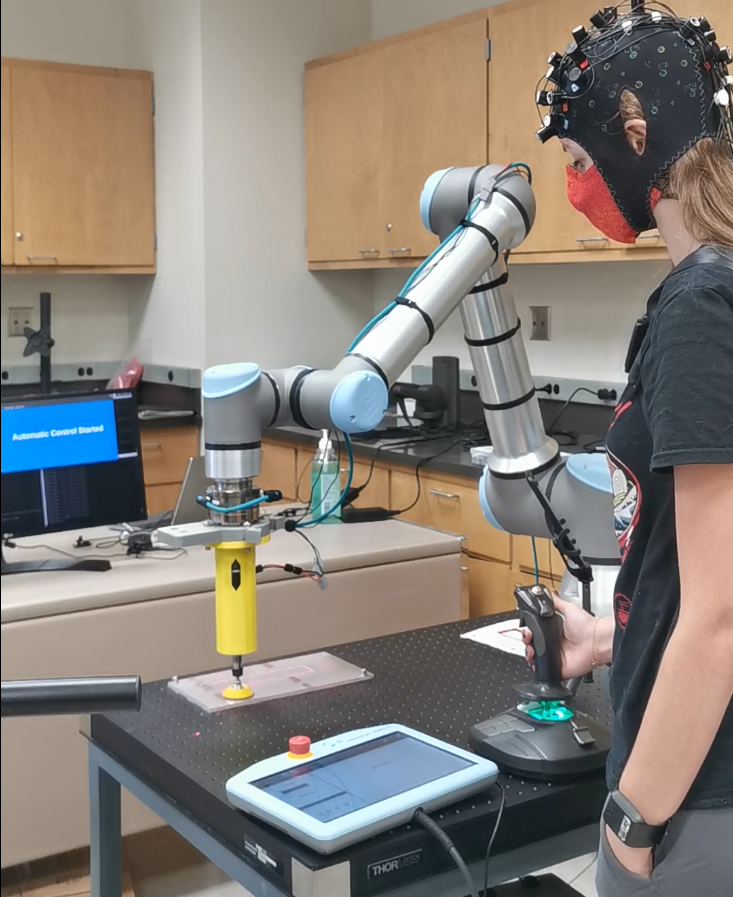

Sarah Hopko, lead researcher and doctoral student, and Dr. Ranjana Mehta, associate professor in the Wm Michael Barnes ’64 Department of Industrial and Systems Engineering, and former graduate student Riya Khurana and Dr. Prabhakar Pagilla, professor in the J. Mike Walker ’66 Department of Mechanical Engineering, are researching the correlation between humans and autonomous assistance in manufacturing settings with large amounts of repetitive work, to determine how a robot can be programmed to step in during human fatigue in a trustworthy manner.

Humans bring flexibility and a high-level of understanding of a production line at a relatively low cost. But because humans have finite physical and cognitive capacities, they become tired and make errors with demanding work tasks. Where humans may lack the capacity to continue, robots can aid in overseeing the more repetitive portions of a task, lifting heavier objects or exerting force depending on the application.

“More and more people are realizing that human-robot collaboration is a viable solution to automate productions or bring a solution to problems that pose difficult or costly roadblocks,” Hopko said.

The goal of this research is to understand how specific human factors, such as fatigue and trust, interact with each other to make sure that the design of a collaborative robot considers the operator’s behavior and needs so that all bases are covered.

“We don’t want the operator to instill a false sense of safety because of their fatigued state and over-rely on the increased assistance of the robot. We also don’t want the operator to under-use robotic assistance when otherwise appropriate,” Hopko said. “Collaborative robots are, to some extent, the operator’s teammate.”

When collaborating with a teammate at work, identifying engagement or levels of fatigue can all be done either through perception or a simple conversation. You can then figure out how best to help your teammate based on the information you have gathered. Hopko says the goal is for human-robot interaction to be the same way.

The research team conducted a multi-session experiment, where men and women performed metal polishing tasks in combination with a Universal Robot (UR10) collaborative robot using varying levels of robotic assistance under different states of cognitive fatigue. Participants were fatigued using a challenging visuospatial working memory task for an hour prior to performing the manufacturing tasks.

Each participant was evaluated for fatigue, situation awareness and workload through wearable physiological monitoring to determine three task performance metrics: task efficiency, accuracy and precision.

Overall, the research team found that the operator’s performance can be improved with increased assistance levels and that increased assistance allows for cognitive fatigue recovery.

Cognitive fatigue and automation levels influence different performance outcomes. Fatigue impeded the efficiency of the participants. Although the levels of accuracy and precision were not affected, it took them longer to complete the task.

“We also found that the female participants reported greater performance benefits from utilizing high automation, while the male participants did not perceive a benefit from the assistance, despite demonstrating comparable task performance,” Hopko said.

This finding is unique and important for robotic technology acceptance with Industry 4.0 advances as more industries are adopting collaborative robots in their work processes.

While increased performance and fatigue recovery are highlighted benefits of robotic assistance, it also showed that higher support reduced the situation awareness of participants by reducing their task engagement and mental stimulation.

Lower situation awareness can result in safety concerns. Thus, higher levels of automation warrant improved adaptivity to operator fatigue states while ensuring human-in-the-loop interactions.

There was also a strong correlation between situation awareness and automation observed in both heart rate variability signals and subjective measures.

“These findings highlight the potential of wearables to help communicate critical information from the operators to the robots,” Hopko said.

Ultimately, greater robotic assistance was able to improve accuracy and efficiency levels, but not precision. The consideration of the interplay between human factors, such as operator sex and their cognitive states, and robot factors on collaborative performance can lead to improved human-robot collaborative system designs.

“We hope to have collaboration between the operator and robot to be as robust to perturbing factors by providing this knowledge unobtrusively to robots to aid in the fluent human-robot adaptation process,” Hopko said.

This work was supported by the National Science Foundation.