The Aggies Against COVID-19 Virtual Competition began in April. Teams of students competed against one another to develop innovations that would help in the fight against COVID-19. The top 10 teams automatically qualified to take part in the National Science Foundation (NSF) I-Corps Site program – a program that provides resources and funding to further the commercialization of student products.

A team of nine students from various backgrounds created the Coro-NO UV-Clave and placed in the top 10 out of 71 teams. Marianela Cintrón and John Karako, from the J. Mike Walker ‘66 Department of Mechanical Engineering, were part of this team.

“I thought this was a great way to get involved and make a difference with everything that was happening,” said Cintrón. “I pulled a group of friends together who were interested, and we created a solution to the mask shortage.”

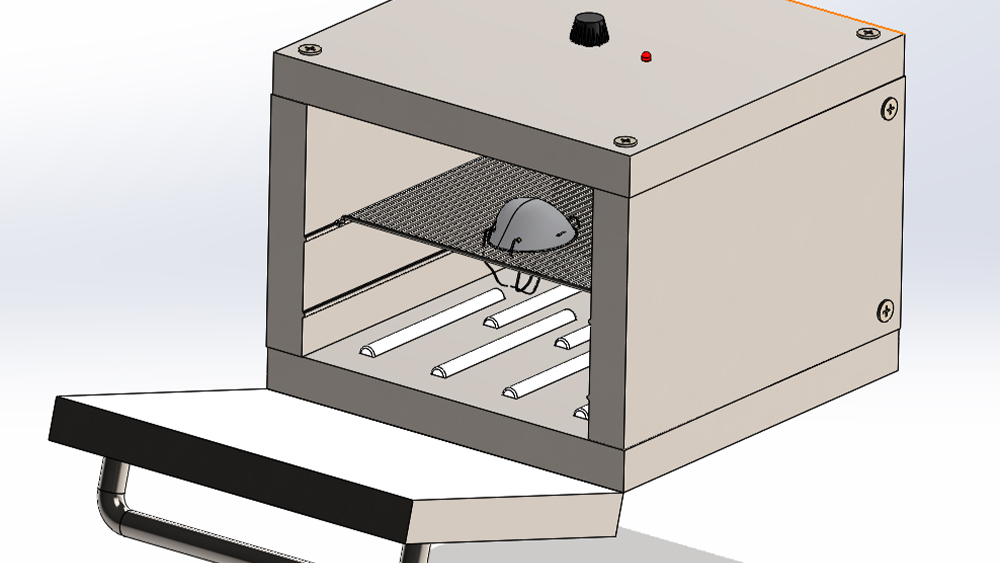

The Coro-No UV-Clave is a light chamber that resembles an oven. Placing an object in the chamber, such as a mask, quickly and efficiently sanitizes that object by using UV-C lighting.

The team completed their project, and placed in the competition, but realized that their product was no longer an original.

This is when the NSF I-Corps Site program provided an opportunity for the team's creation to evolve through engineering entrepreneurship and adaptations to their original product.

“By the time we finished the design and presented it during the competition, there were tons of products like this already on the market,” said Karako. “(NSF I-Corps Site) reached out after we placed in the top 10 and offered to fund changes to the project, and four of us decided to continue working on it.”

The team of four includes Karako, Cintrón, Tyler Hope and Jerry Reiger. Hope is working toward a double major in biochemistry and genetics, and Reiger is a geographic information science and technology major. Their revised product is called Sterilight.

According to Karako, the primary change from their original invention is stopping the use of UV-C in exchange for another light source, far UV-C. This change eliminates potentially harmful radiation that is associated with UV-C lights. As Cintrón also pointed out, far UV-C has a broader range of materials it can sanitize.

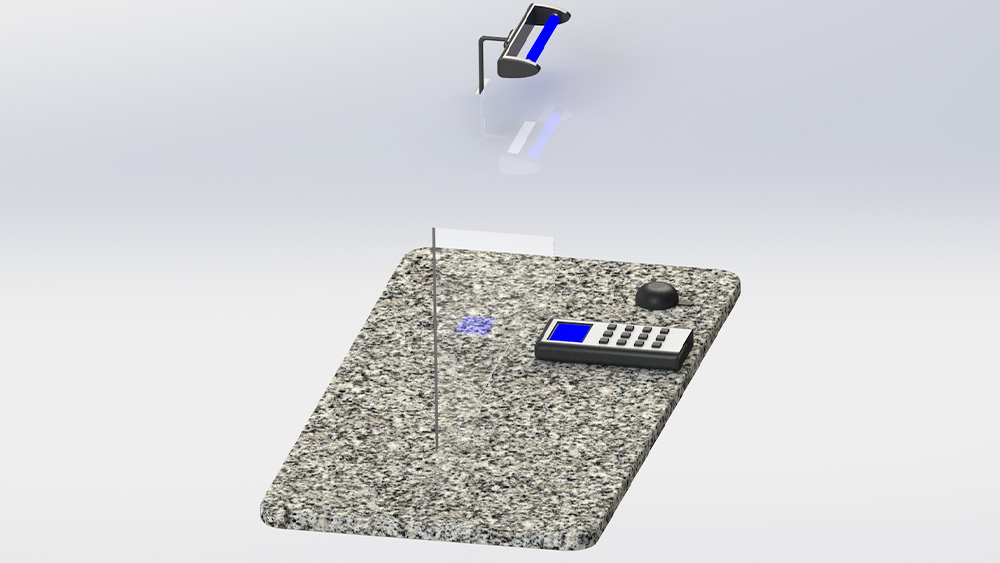

Sterilight construction is ongoing, and the team is conducting research, developing the product and looking for other areas their concept can be used in with the help of the NSF I-Corps Site program. Their most recent prototype aims to sanitize objects and areas that are constantly being touched.

“We are hoping that once we complete our design, it can be implemented in K-12 and colleges so that the fear of transmission through using community objects, such as crayons or lab supplies, is diminished,” said Cintrón.

Along with schools, another effective use could be in stores.

“Stores may sanitize their credit card readers every 30 or 60 minutes,” Karako said. “Many people go through in 60 minutes and obviously you can’t clean it after every person. If we have a constantly cleaning light, then it’s a hotspot that’s being constantly cleaned.”

Karako and Cintrón are working with their team to create a final prototype of Sterilight and contacting local institutions to determine how to improve their product. They will receive a certificate of completion from the program, potentially qualifying the team for an additional $2500. Through the help and guidance of the NSF I-Corps Site program, they hope to demonstrate their invention’s entrepreneurial potential and aid in the battle against COVID-19.