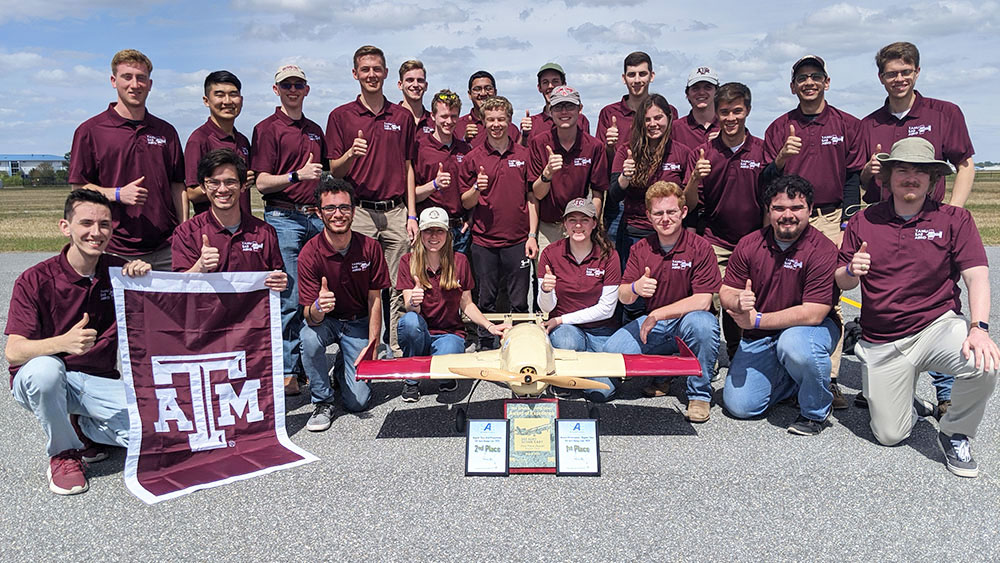

In March, Texas A&M University’s Society of Automotive Engineers (SAE) aero design team took first place in the 2020 SAE Aero Design East competition in Lakeland, Florida. This achievement is one Texas A&M has only seen once before in its 10-year history competing.

The competition, intended to immerse students in real-world engineering situations, challenged teams from across the globe to design and optimize an aircraft to meet a specified set of configurations and mission requirements. This year’s objective was to design an aircraft to successfully take off within 100 feet while carrying a payload of steel and soccer balls. The more payload an aircraft was effectively able to carry, the higher the score.

In addition to the set of rules, teams received an equation that allowed them to determine how much they could score on any given flight, which helped to inform the design process.

“From the get-go, we determined that we were going to understand and use that equation to make sure we weren’t just setting an arbitrary design goal for ourselves,” said Jack Kassing ’20, an aerospace engineering major and team director. “We spent two weeks before we ever started designing doing calculations."

After meticulously analyzing the equation and variables in their control, the Texas A&M team, Farmers Flight, confidently opted for a small wingspan design despite larger wingspans being the more efficient option in prior years of this design competition.

“I’m not sure I fully appreciated how strange it was until we got to competition and saw the other planes,” said Kassing. “It was by far the smallest wingspan. Most teams designed to the limit, which was 10 feet.”

Farmers Flight’s aircraft was roughly half that size and quickly attained speculation from the other teams and judges when they arrived in Florida.

Despite others’ confusion, the team was well versed in the parameters and knew a small wingspan held the most potential. However, reaching that potential required an untapped commitment from Texas A&M’s SAE team.

Preparing for takeoff

Because they were working with a design unlike any previous SAE aircraft, the team was limited on what knowledge they could use from prior experience. Their unconventional design also meant being unable to fully rely on what simulation software could tell them, so to best work through their designs, the team logged an impressive 11 trips to the runways at the RELLIS Campus to conduct a series of flight tests.

“It was an aerodynamic challenge to maximize the amount of lift we could get out of a small wingspan aircraft, so the flight tests were all about refinement,” said John Blausen ’21, a mechanical engineering major and the team’s chief engineer.

Farmers Flight’s first nine flight attempts were unsuccessful, challenging the team to face one problem after another.

“It was tough, but ultimately it was that challenge that allowed us to outperform the others in competition,” said Blausen.

Devoting hundreds of working hours to their design after every flight gave the team a well-rounded knowledge of their aircraft. The constant reevaluation of their design also offered members a practical experience that translated to and from the classroom.

“SAE improved my learning experience because I had real-world examples in front of me that gave me context for what they were teaching me in class,” said Blausen. “I was learning equations that I could go home and apply to the work on our aircraft.”

Overcoming turbulence together

Although their hard work paid off, pursuing a design that demanded extensive testing required a team of students willing to pick back up time and again and put in the effort to understand and adjust their aircraft.

For Kassing and Blausen, keeping up morale was as intentional and imperative as the refinement of their design.

"A project like this does not happen unless everybody's engaged in it," said Kassing. "I think John and I did a good job of stepping right back into it after a crash and saying, ‘OK, let’s pull up our sleeves and fix the problem and go out and do it again.’”

In addition to the leadership from Kassing and Blausen, the team found motivation in their advisors' support.

"The biggest impact our advisors had was motivating the team," said Blausen. "Brad Worsham and Scott McHarg took time out of their weekends to come and fly for us. I think that their commitment to do that every single week, and sometimes twice a week, was really motivating to the members."

Farmers Flight made continuous changes in the grueling months leading up to competition, and with only a month left, managed to complete 10 consecutive successful flights, locking in their confidence.

"It was a symbiotic relationship between shooting very high and having a team drive and organization that was able to make that happen," said Kassing.

Coming in for a smooth landing

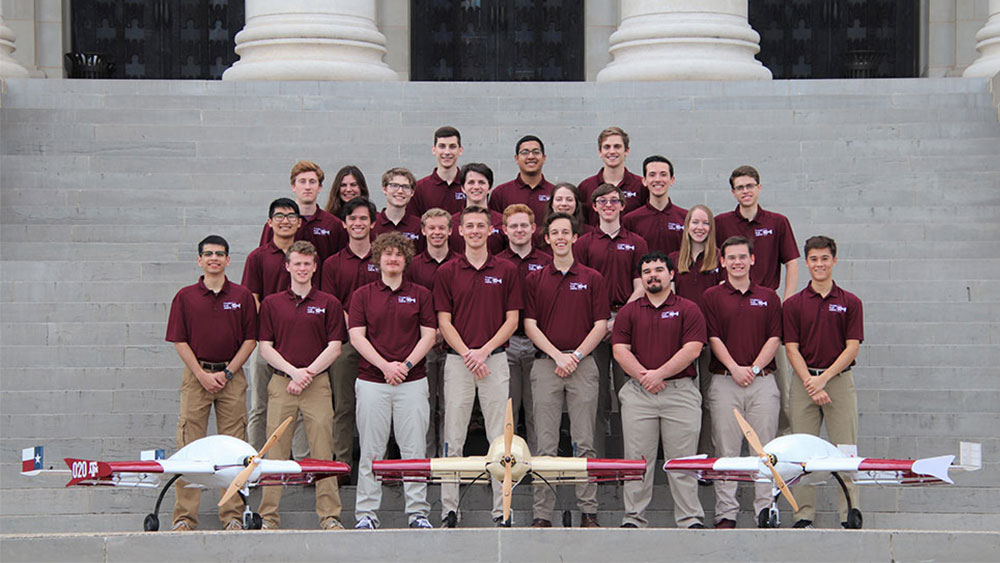

From December to March, the team ended up building a total of five aircrafts plus a wind tunnel model and prepared three aircrafts for competition.

“I think most people knew that Texas A&M came to compete, but they might have been caught off guard that ours performed as well as it did,” said Blausen.

Despite the doubt their small-winged aircraft received from teams and judges, Farmers Flight’s perseverance leading up to competition equipped them with everything they needed to succeed.

“This year, we did numerous flight tests, so we knew exactly what conditions our plane could fly in,” said Blausen. “We had the experience and the confidence to push the limits, and as a result, by the end of day one we’d already scored enough to win.”

This year’s win pulled Texas A&M’s SAE aero design team out of a six-year slump. As gratifying as the victory was for the team, their takeaways extend beyond a first-place award.

“To see people grow from being not too self-assured about the things they’re designing to stepping in at competition and suggesting solutions was amazing,” said Kassing. “The value behind seeing our team gain confidence in engineering and the intuition which that practical experience builds is incalculable.”

Farmers Flight competed against teams from India, Czech Republic, Poland, Brazil, Mexico, China and Canada. Along with placing first overall, Farmers Flight received first place in mission performance and second place in oral presentation.

Learn more about Texas A&M’s SAE design team and the annual SAE Aero Design competition.