As the COVID-19 pandemic puts more demands on research, many engineers have found ways to adapt their current projects to help solve these problems.

Jose Wippold, doctoral student in the Department of Biomedical Engineering at Texas A&M University, is adapting the high-throughput microfluidic sensor that he has developed to expedite the process of looking for neutralizing antibodies that can prevent COVID-19.

For his doctoral work, Wippold works in the multidisciplinary NanoBio Systems Lab in the Department of Electrical and Computer Engineering, directed by Dr. Arum Han. His project has been working on developing a system that can rapidly detect neutralizing antibodies, molecules that can block the infection of host cells by viruses, using a droplet microfluidics-based lab-on-a-chip approach.

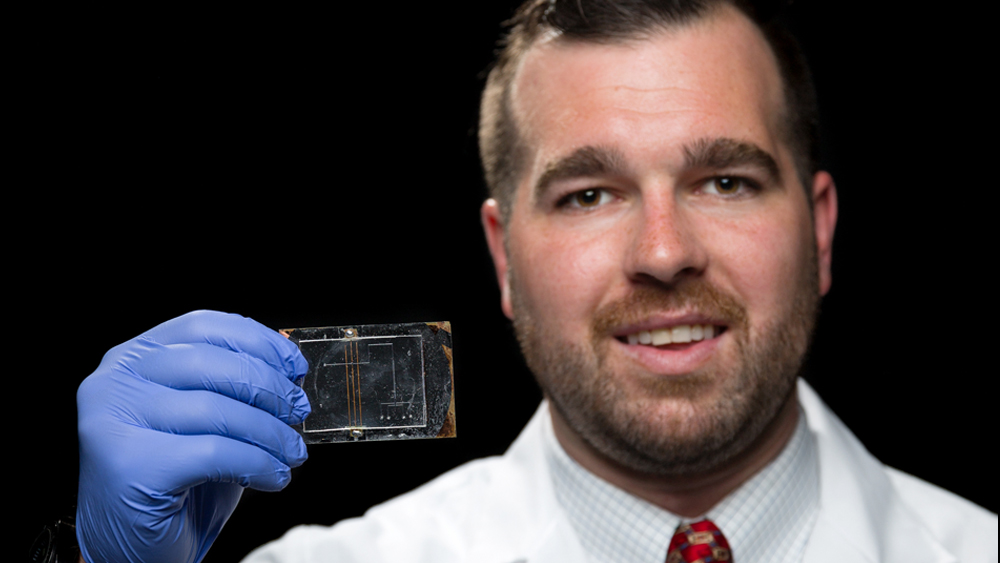

Called the “Platform for the Rapid Evaluation of antibody SuCcess using Integrated microfluidics ENabled Technology,” or PRESCIENT, this platform allows human B cells encapsulated within a water-in-oil emulsion droplet to be scanned on a device the size of a credit card. It will look for those particular B cells that produce infection-neutralizing antibodies, at a speed of 10s to 100s per second, much faster than what conventional tools can perform.

Wippold said PRESCIENT as a project started about four years ago as a means to combat emerging viral threats. He saw how his work could easily shift to help develop vaccines and immunotherapeutic agents for COVID-19 because discovering and identifying a neutralizing antibody to fight the virus and prevent infection is the first step in such countermeasure development.

PRESCIENT can quickly perform this test on a large number of samples, which can help speed up the process to further understand COVID-19 and what antibodies may be able to fight against it.

“I truly believe PRESCIENT has the chance to accelerate our neutralizing antibody discovery process and rapidly take it to a level that is capable of combating emerging viral threats,” Wippold said.

Wippold is supported by a Department of Defense Graduate SMART Scholarship and wanted to join the Army Research Laboratory’s biotech group to work in sensors and electronic devices. He said he appreciates the high levels of support, expertise and access to unique equipment provided through the partnership.

Since restrictions have been put in place to limit the spread of COVID-19, Wippold said he can continue to work in the lab but follows new guidelines — he wears a mask and gloves at all times in the lab, and meticulously and repetitively decontaminates surfaces in the lab, among other adaptations.

Wippold said this hasn’t deterred him; the pandemic has only renewed his motivation to continue pushing the boundaries of biotechnology, medicine and patient health with a new generation of advanced technologies.

“For me personally, the current pandemic has highlighted exactly why we need a platform like the one I have been developing over the last four years,” Wippold said. “Also, the need for immediate therapeutics has opened up opportunities to apply my biochip into potentially aiding the discovery process for SARS-CoV-2 neutralizing antibodies.”