Having an IV put in your arm is not a pleasant experience. If it moves for some reason, the fluid will leak into the tissue instead of the vein through extravasation, which can be painful. Now imagine being an infant and not knowing how to express that pain in an effective way except for how babies do best — crying.

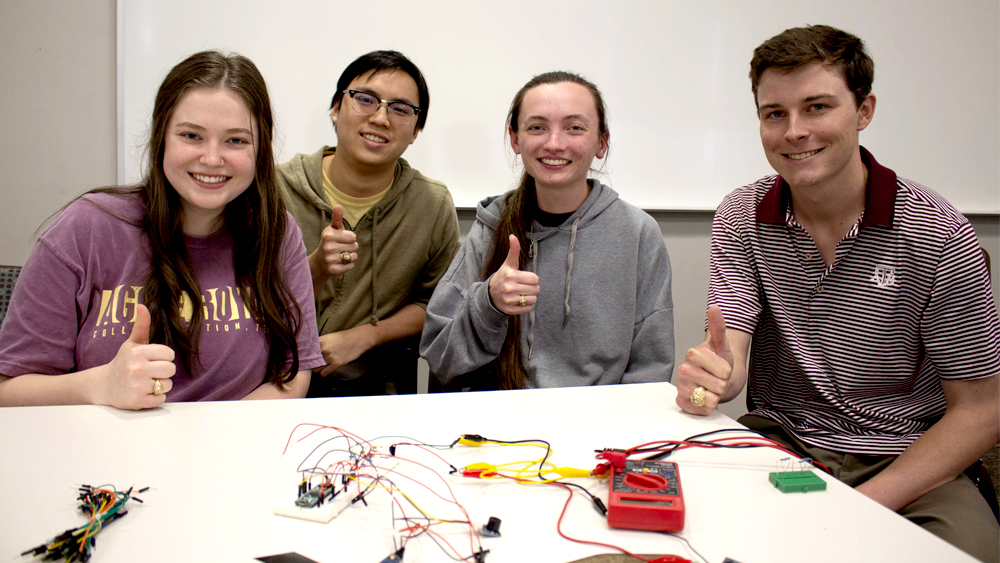

A senior capstone design team in the Department of Biomedical Engineering at Texas A&M University developed a detection system to reduce the tears shed and help the workload on nurses checking on these hospitalized infants.

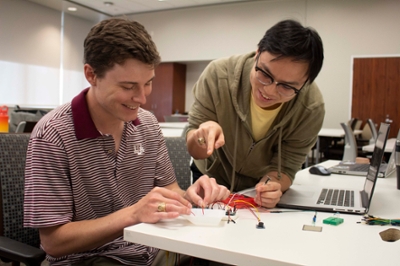

The team worked with Texas Children’s Hospital to design and prototype an extravasation detection system that senses changes in temperature, swelling and leakage at the insertion site and alerts the attending nurses.

“If it is able to efficiently monitor that IV site, the nurses wouldn’t have to constantly worry about it,” said Daniel Wang. “I feel like they are still going to check during rounds, but this device can act as a backup system for them if something were to happen.”

Because the device will mainly be used on babies, developing a tool without choking hazards was a challenge. As the team was told, anything that can fit through a toilet paper tube will cause an issue.

“Making sensors that are small enough but also spread out enough to actually diagnose the symptoms was an issue,” said Nolan Rizzo. “The symptoms may not be just at the insertion site, they could appear somewhere else. We have to design a dressing that’s the proper size to not only fit on a really small baby’s arm, but also big enough to have a range of area to diagnose the symptoms.”

Unlike previous projects in their coursework, capstone projects require students to work together on the same need statement for two semesters. During the first semester, teams conceptualize and plan their designs, while the second semester is mainly for developing a tangible prototype they present at the end of the semester. Emily Zagrzecki said having the opportunity to gain new skills in prototyping was a highlight for her.

“My favorite thing to do is hands-on projects, so just getting to build it has been really exciting,” Zagrzecki said. “Every time something works, we get so excited, and it’s cool to see it all get pieced together.”

Even after spring break, when all Texas A&M courses moved to an online/distance format due to COVID-19, Jim Machek, senior design instructor, said he was impressed with the students’ ability to adapt and still complete prototypes.

All seniors in the department take part in the capstone program, which allows them to put their classroom skills and knowledge to the test on a real-world project.

The senior capstone allows students the chance to reflect on how far they’ve come since starting in the engineering program. For Lauren Kwiatkowski, even finding her way to biomedical engineering was an adventure.

“I was a little lost senior year of high school,” Kwiatkowski said. “I ended up printing out information on every major and then crossing out the ones I wasn't interested in. I thought biomedical engineering was the perfect intersection of biology, the human body and engineering, and here we are.”