Three interdisciplinary student teams, led by their faculty advisor Dr. Wayne Hung, won top prizes at two student competitions that were held earlier this year.

The Society of Manufacturing Engineers (SME) organizes manufacturing events at major manufacturing hubs across the United States. On Feb. 23-25, they hosted a 3D printing student competition during the HOUSTEX manufacturing exhibition event at the George R. Brown Convention Center in Houston.

This competition encouraged students to be familiar with engineering design and ideation by:

- Creation of 3D concepts, innovative ideas applied to products that reduce energy and waste

- Recycling wasted products to conserve resources

- Understanding additive manufacturing processes and limitations

- Being energy conscious

- Enhancing manufacturing knowledge with a guided tour at the HOUSTEX exhibition

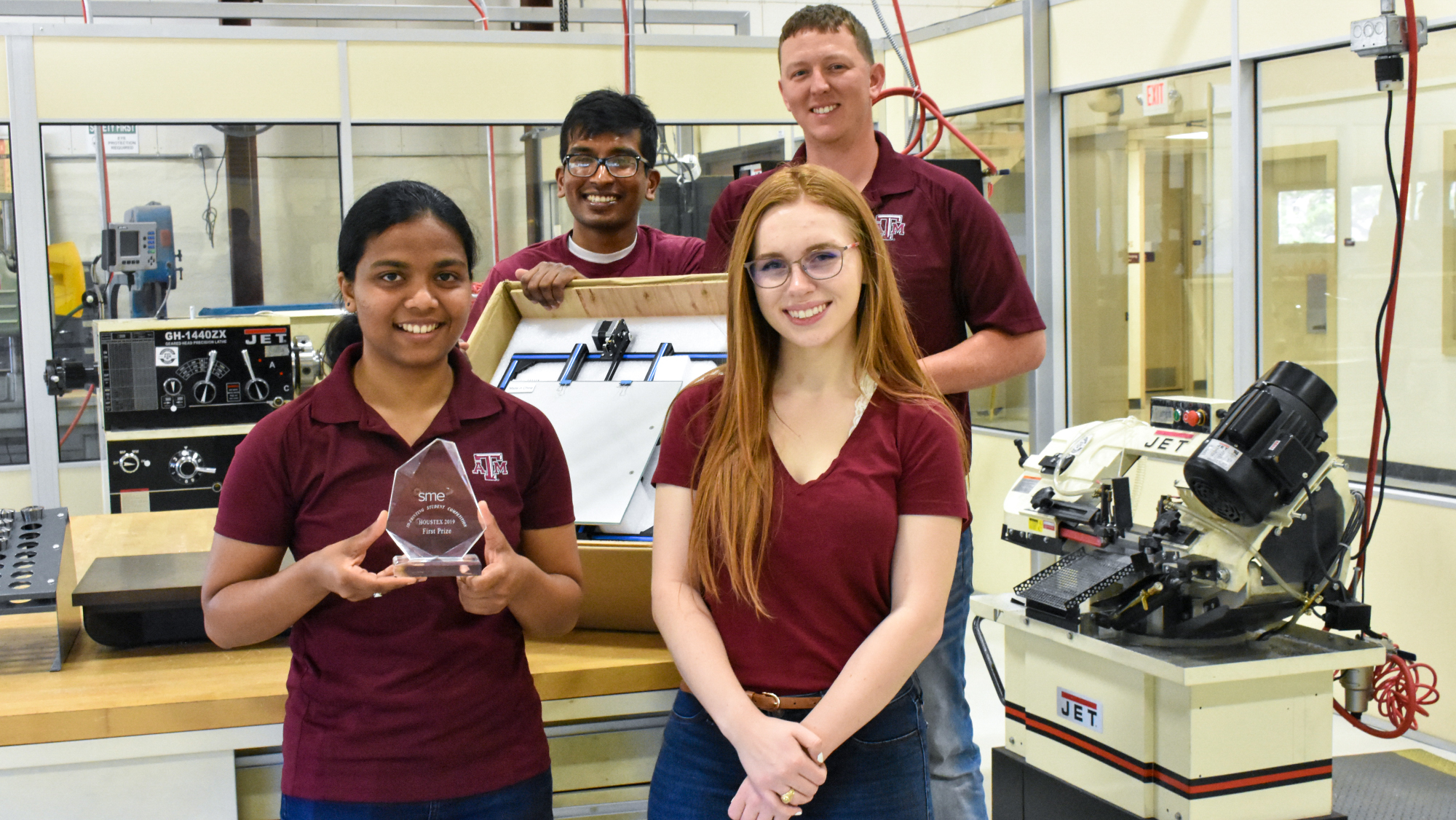

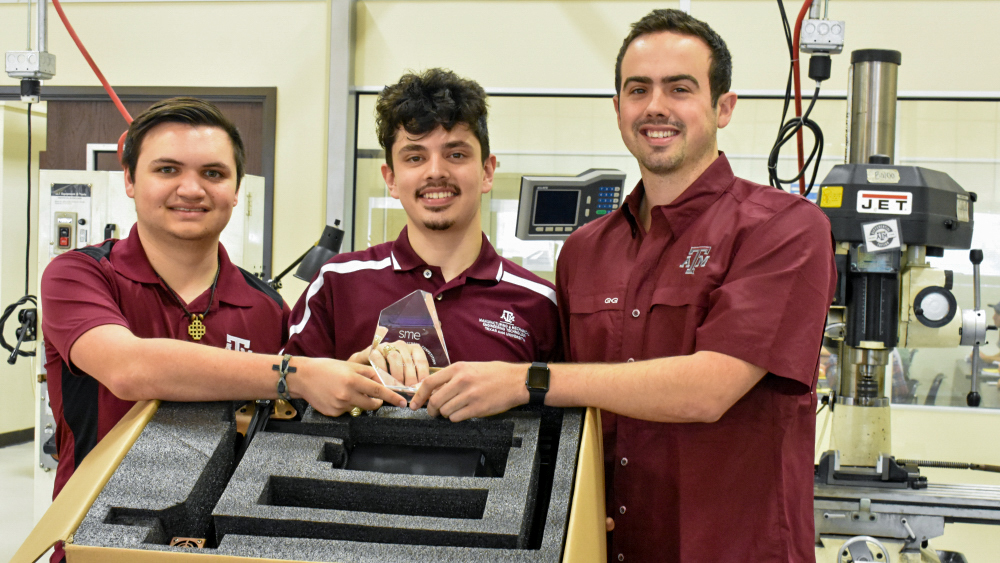

Two teams won first and second place while competing against 13 other teams from across the country. The teams came up with environmentally friendly solutions by using recycled biomaterials such as coffee powder and saw dust for 3D printing useful objects. Each team won a cash prize, new 3D printers of their choices and plaques from SME.

In April, Manufacturing and Mechanical Engineering Technology program students Kenny Adams, Benjamin Siperek, Jimmy Jaraczewski and Matthew Retault competed against more than 90 international teams at the Aluminum Extrusion Competition and placed second.

The competition challenged designers and engineers to think about aluminum extrusions as a holistic solution to a design problem by creating a product or system that includes at least one extruded aluminum component.

Solutions that have already been created include high-impact glass, plywood and installing exterior shutters. However, these designs can be expensive or have a very cumbersome installation process as well as being permanent or requiring nails to be driven into the walls of the structure. The design the team came up with is a compression system that holds plywood or other material securely in front of the area it is protecting.

The team received a scholarship prize and certificate.