Mere months away from graduation and the start of a career at The Boeing Company, senior mechanical engineering student Cade Capps is leaving Texas A&M University a little bit greener than it was when he arrived.

Through his work in building an enhanced burner for combustion research, leadership and years of dedicated research in the J. Mike Walker '66 Department of Mechanical Engineering, Capps has set the stage for the design and development of cleaner and more efficient automotive engines.

“I first learned about working on vehicles from my dad and absorbed as much information as I could from him,” Capps said. “Then, when I got into my thermodynamics class and discovered that we were learning about the fundamentals of how engines operate, I became completely hooked.”

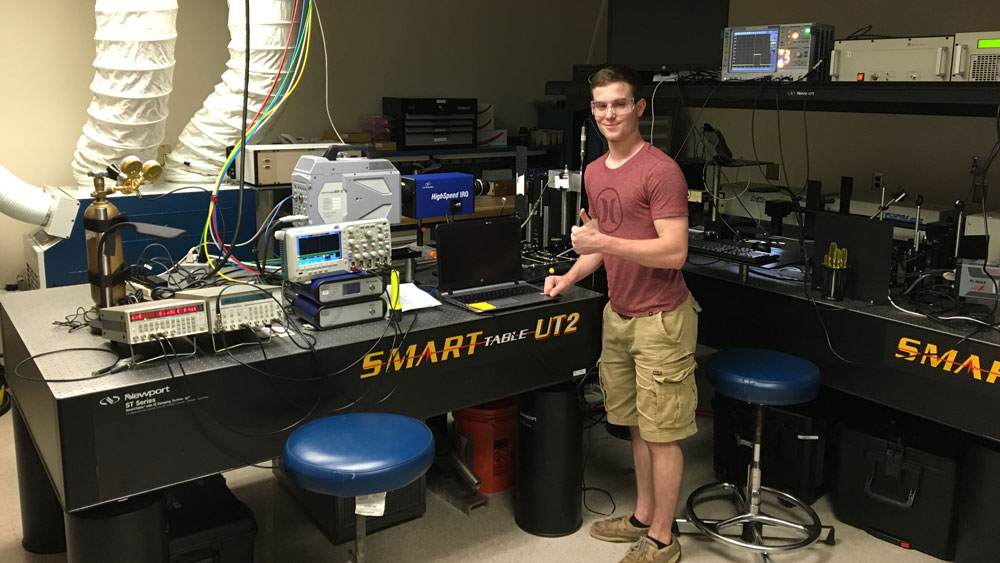

Harnessing his passion for mechanics and melding it with his newfound academic curiosity, Capps began his research journey in the Optical Diagnostics and Imaging Laboratory, directed by Dr. Waruna Kulatilaka, associate professor and Morris E. Foster Faculty Fellow I in mechanical engineering.

There, Capps helped set up and run laser-induced fluorescence experiments, streamlined data acquisition systems and created programs to decrease the time it took to analyze data.

His devoted work eventually granted him the opportunity to conduct an integral research project in the lab: the systems integration of a combustion burner to simulate the liquid-fuel combustion process inside a gas turbine combustor or an internal combustion engine.

Laboratory burners play a vital role in simulating engine operating conditions in order to help researchers investigate fuel efficiency and levels of emissions using advanced laser diagnostics.

“I enjoyed having the freedom to be creative by combining a nebulizer with a syringe pump to create a fine mist of fuel, which is highly desirable as it results in better combustion characteristics and air-fuel mixing,” Capps said.

His burner has become a cornerstone at Texas A&M for ongoing simulation and optical diagnostic experimentation, which aims to capture the complicated phenomenon of combustion to gain further insight into the creation of cleaner engines.

“Cade has worked diligently in assembling our piloted liquid-fuel spray burner, which is now being used for a variety of research studies,” said Kulatilaka.

After completion of that project, Capps transitioned into the Computational Thermo-Fluids and Energy Systems Laboratory, directed by mechanical engineering assistant professor Dr. Dorrin Jarrahbashi. He continued to expand his knowledge, research and expertise through the use of computer simulation and modeling.

Such simulations offer a quick and cost-effective alternative to traditional studies that allow researchers to expand upon physical experiments by approximating unknown data points based upon known variables. This in turn lets researchers extrapolate the results of an experiment under varied, programmed circumstances.

Harnessing such technology, Capps became involved in a simulation project that Jarrahbashi and Kulatilaka were conducting that involved using the piloted spray burner he helped create to study liquid fuel combustion.

For Capps, the project offered another opportunity to enhance engine efficiency and apply the knowledge he gained from working alongside his father.

Since then, Capps and Jarrahbashi have been funded by Cummins to investigate the direct injection processes of diesel fuels and their spray formation to observe how different thermo-fluid dynamic parameters effect the combustion process of engines. Their results from this ongoing project will help to discern how to achieve optimum emissions, fuel economy and performance in commercial vehicles, like trucks.

Among the applications of Capps’ combined research from both labs are such things as making transportation more cost effective, reducing harmful vehicle emissions and supporting military personnel in situations where the performance of an engine could mean the difference between life and death.

“The high-paced learning and the engineering experience I gained has opened many doors for me that I would never have thought possible coming into Texas A&M as a first-generation college student,” Capps said.

Now, as his time at Texas A&M comes to a close, Capps has shifted gears in his research once more.

Moving away from experimentation and data gathering, his final project, aligned with the National Science Foundation’s Broader Impacts guidelines, is to pave the way for future engineering students to take up the torch and continue his research.

“The idea is to create a user-friendly program that can be run by high school students so they can toggle between different parameters, observe changes and understand how injectors and general internal combustion engines work,” said Capps. The goal is to create a straightforward research module in order to motivate students to pursue studies in engineering and STEM-related fields.

By working on this final project, Capps’ final walk across the stage at graduation is only the beginning of his impact on the future.