Story Overview

The principal investigators for the Autonomous Material Discovery and Manufacturing via Artificial Intelligence project include Dr. Bukkapatnam, Dr. Ding, Dr. Karaman, Dr. Arróyave, Dr. Kumar, Dr. Jianhua Huang and Dr. Bani Mallick (statistics), Dr. Doug Allaire (mechanical engineering), Dr. Dimitris Lagoudas (aerospace engineering), Dr. Xiaoning Qian (computer engineering), Dr. Joseph Ross (materials science and engineering), and Dr. Ravi Sen (Mays business school).

The Autonomous Material Discovery and Manufacturing Using Artificial Intelligence project, funded by several sources including the National Science Foundation and the new Texas A&M University X-Grants program, is helping researchers at Texas A&M University forge a novel path to create materials that are yet to be discovered.

Creating new materials involves conducting tedious experiments that take decades of work. Soon artificial intelligence (AI) may be used to find the exact materials needed for any situation, resulting in less material waste and increased progress in developing future products, the vast majority of which will use materials that are yet to be discovered.

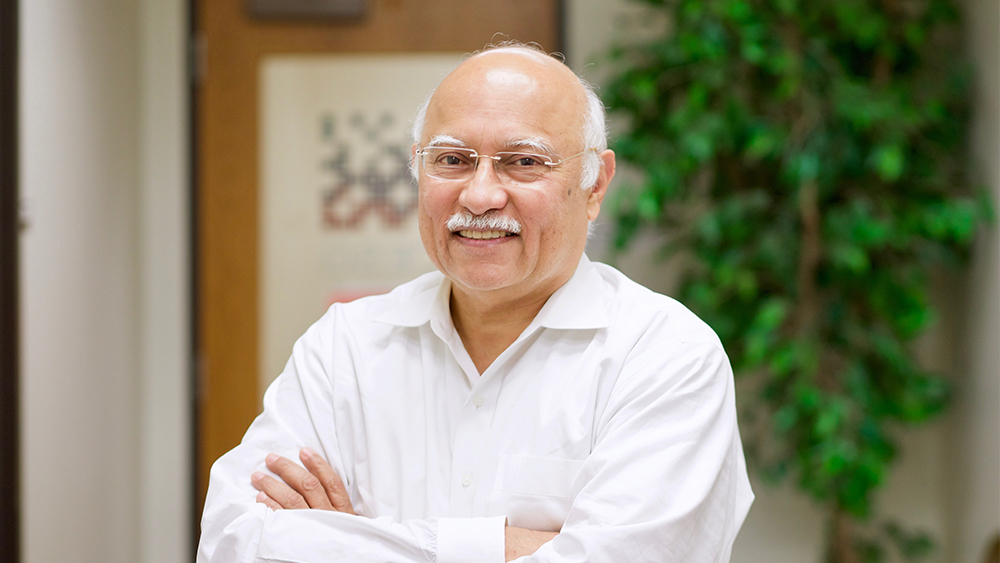

The grant allocates $500,000 toward project planning for 18 months, ending in December 2019. “We greatly appreciate the university’s generosity and support,” said Dr. Satish Bukkapatnam, principal investigator, industrial and systems engineering professor and director of the Texas A&M Engineering Experiment Station's Institute for Manufacturing Systems. “The X-Grants are all about leveraging our collective strengths to address grand societal challenges,” Bukkapatnam said. “Texas A&M has thriving research areas in materials science, artificial intelligence, data science and manufacturing research, thanks to investments in facilities and professors. This project will bring all of these strengths together.”

The bottleneck in 21st century inventing

Materials scientists and engineers design new materials, particularly metals and alloys, to enhance their performance for use in aerospace, defense, biomedical and other applications.

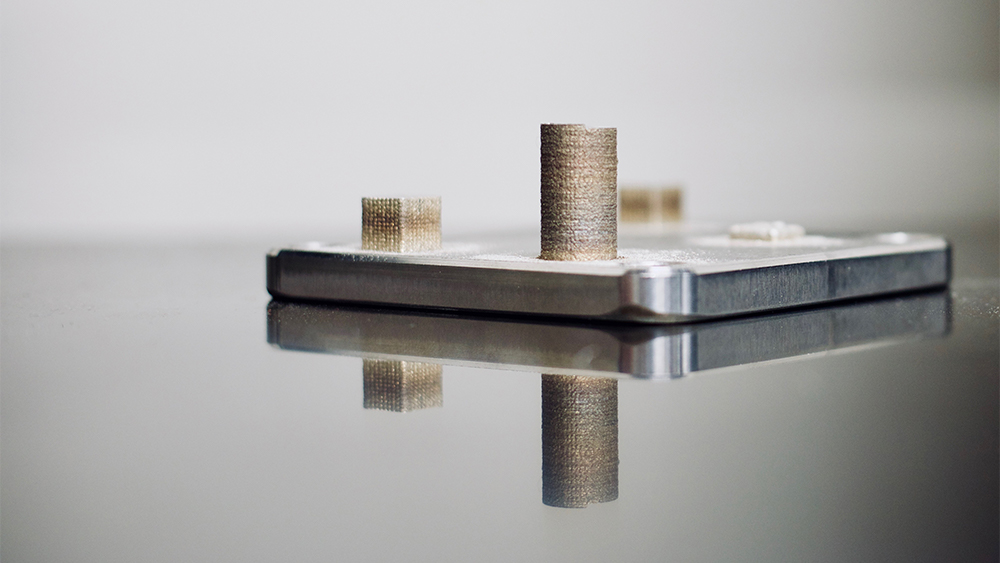

Material discovery is the bottleneck to creating highly functional and 3D printed parts with an industry average for material discovery of 15 years.

In the last 20 years, materials scientists have worked to accelerate the design of materials. In 2011 the Materials Genome Initiative proposed the synergistic use of data, advanced computations and sophisticated experiments as a way of making this a reality.

As engineers search for a specific material to fit a project, they consider many different properties including the distribution of the materials, temperature, strength and structural integrity.

“My colleagues and I have been discussing this challenge for at least a year,” Bukkapatnam said. “The X-Grant provided the funding needed to solve this problem. 3D printing represents a new frontier, but it alone could not solve the problems of materials. We knew there had to be a better way. What material will you use to print? What intelligence can we use to 3D print and choose materials? We have to create new knowledge.”

The closed loop solution

“Material discovery will transform from the work of human scientists to an autonomous experimental platform,” said Dr. Yu Ding, industrial and systems engineering professor at Texas A&M University and co-lead of the project.

Tackling this enormous challenge requires three different kinds of expertise:

- Materials science and engineering: the knowledge of how elements come together, their properties, the processing structure and property relationship.

- Advanced manufacturing: how the material can be processed and how to create different shapes from a material.

- Data science and AI: how to quickly assess the data and improve efficiently instead of through trial and error.

The smart hybrid platform will consist of a software “brain” that will run the experiments autonomously through simulated workflows, using a form of machine learning that automatically predicts the next best step. The computer’s hardware can then create the product, assess it and repeat the process until an optimal match is found. The brain will be able to test and assess dozens of options at once, testing for pressure, shaping, temperature and more. The platform will be materials agnostic, meaning it will work for any material.

Experiments will be completely autonomous and able to use little to no input data creating a closed loop system.

“A truly autonomous materials discovery platform will transform the way materials scientists think about the entire materials discovery cycle,” said Dr. Raymundo Arróyave, materials science and engineering professor at Texas A&M and co-lead of the project. Arróyave will provide computational domain expertise.

“Materials discovery is the future of this country,” said Dr. Ibrahim Karaman, department head of materials science and engineering at Texas A&M University, and co-lead of the project. Karaman’s role is to help fabricate bulk new materials in a high throughput fashion. “The Department of Defense is invested in discovering, developing and designing materials much faster,” Karaman said.

The materials portion of the project will use instruments funded by the Air Force Office of Scientific Research and Texas A&M’s Research Development Funds.

“Models can be created, and even models of models (metamodels) will be created, but in the end physical testing must take place,” Ding said. He plans to use engineering data science to reduce a large amount of raw data points from dynamic imaging data to a handful of key process indicators. The filtered data will then lead to better decision making.

The machine learning system will use both experimental data and prior knowledge to actively formulate the next experiment to meet the target specifications. “Active learning will allow researchers to design the next experiment from which to learn,” said Dr. P.R. Kumar, electrical and computer engineering professor and a co-lead of the project. It marks the beginning of a new era in learning for materials discovery.

“In the end, the discovery platform may give us even a better answer than we hoped for,” said Bukkapatnam. “It may discover a material that even exceeds the expectations for the experiment.”

Collaboration: The key to progress

“It is an interdisciplinary problem,” Kumar said. “Without a multidisciplinary initiative of this sort, I would not normally have been involved in a research project with materials scientists. Researchers from diverse backgrounds are coming together and sitting at a table. From a Texas A&M point of view, we have a fantastic team and we’re ready to try to create a breakthrough.”

Several professors have selected their graduate students or post-doctoral fellows. They will have the opportunity and financial support to work on a project that could change the course of manufacturing as well as contribute to the field of machine learning.