Researchers at Texas A&M University are uncovering new methods of working on the nanoscale, which could ultimately lead to the development of more advanced electronics and environmentally friendly engineering practices.

Lead researcher Dr. Jonathan Felts, an assistant professor in the J. Mike Walker '66 Department of Mechanical Engineering, was recently selected for the National Science Foundation Faculty Early Career Development (CAREER) Award for his work, an honor designed to allow promising junior faculty to pursue cutting-edge research while simultaneously advancing excellence in education.

“The CAREER award means the world to me,” Felts said. “It will allow me to pursue cutting edge research in nano-electronic device fabrication at the intersection of a wide range of disciplines,

Felts and his team are conducting research that could open the doors to several significant technological improvements by adding more complex functionality at a physical level smaller than the current state-of-the-art.

"I foresee our work providing insight into engineering surfaces with less friction and wear, making optic and electronic devices with more sensitivity and efficiency than current technology," Felts said.

Efficiency, in particular, is a significant focus of the team's research as they seek to develop more reliable ways to engineer surfaces at the atomic level.

If successful, Felts said the research could hold the answers to challenges such as creating faster electronics that dissipate less heat, engineering highly sensitive optical sensors with faster response times and mitigating friction and wear at moving interfaces.

Additionally, the research could also help provide answers on how to generate essential chemicals while limiting toxic waste and excess energy consumption through the development of new strategies for chemical synthesis using mechanical force, as well as creating new molecules not possible by any other means.

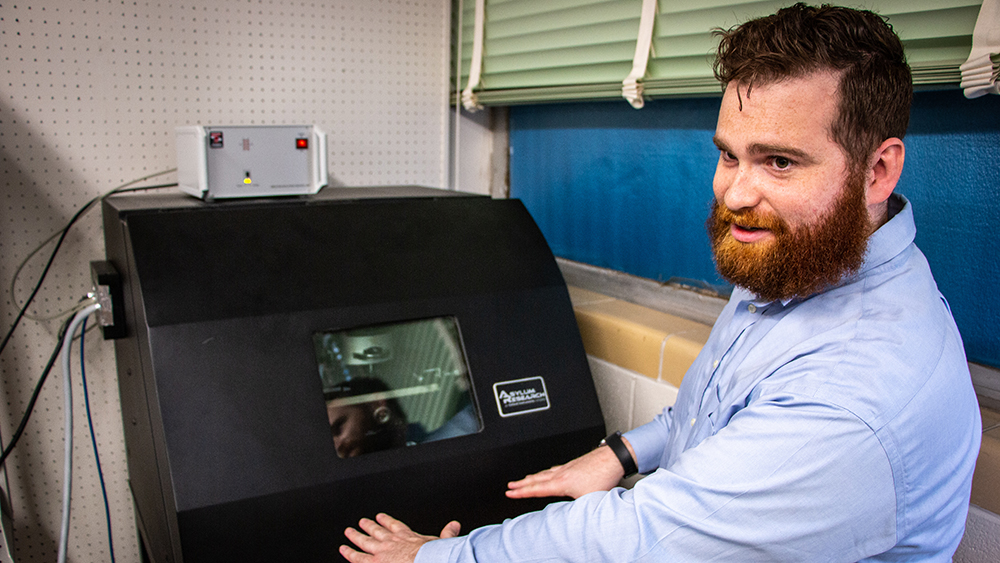

Among the team's main objectives in the research is to develop techniques to drive complex multiphysical processes on surfaces at the nanoscale, with a primary goal of locally tuning the properties of surfaces to impart functionality, such as drawing electrical circuits, optics, magnetic domains and hydrophobicity/hydrophilicity.

"From the standpoint of functionality, if we can expand our ability to manipulate chemistry on the level of a handful of atoms, we can dramatically expand the landscape of possible devices, as well as the integration of those devices, into other objects," Felts said.

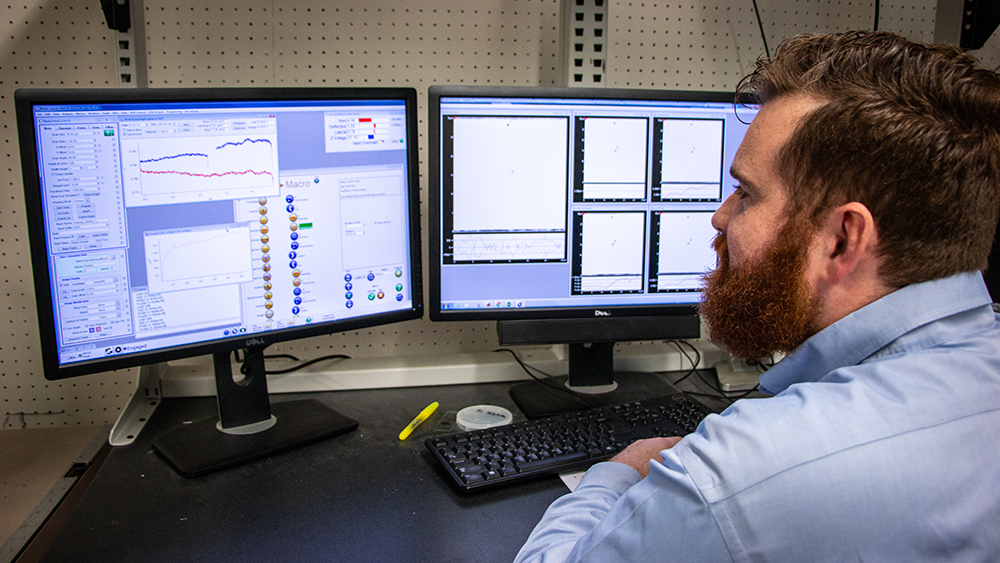

Felts said the research is a multidisciplinary endeavor, drawing on the use of mechanical force, chemical reactions, atomic physics and more. Through the study and application of these methods, the team has been able to discern fundamental properties that are helpful in developing the ability to better plan for and predict the behavior of the processes on multiple levels.

"Developing techniques to create these functional surfaces involves quite complex physical processes," Felts said. "Our work also uncovers fundamental insights into macroscale surface phenomena, such as friction, wear, and thermal and mass transport."

Where Felts’ research diverges from others conducting similar research is in its primary focus on understanding the fundamental physics behind the use of nanomanufacturing methods rather than demonstrating the concepts which, through trial and error, have been shown to work.

"Unfortunately, the lack of fundamental understanding limits the predictive power of the developed methods," Felts said. "We spend a lot of time investigating the fundamental physics behind the nanomanufacturing methods. Our hope is that the improvements in fundamental understanding will enable techniques and processes that would be otherwise difficult to stumble across phenomenologically."