Engineers are product innovators, but traditionally their sole focus is on technology development, where they rarely have a hand in their own product commercialization. This can leave them at a disadvantage when developing a product that will fit consumer needs. The Texas A&M University Innovation Corps (I-Corps) Site Fellows program is addressing this disadvantage by providing student researchers the skills and resources to conduct market research and evaluate the potential of their innovation.

“The best way I could describe this program is teaching you how to make the plan before the business plan,” said Monica Hwang, a chemical engineering doctoral student.

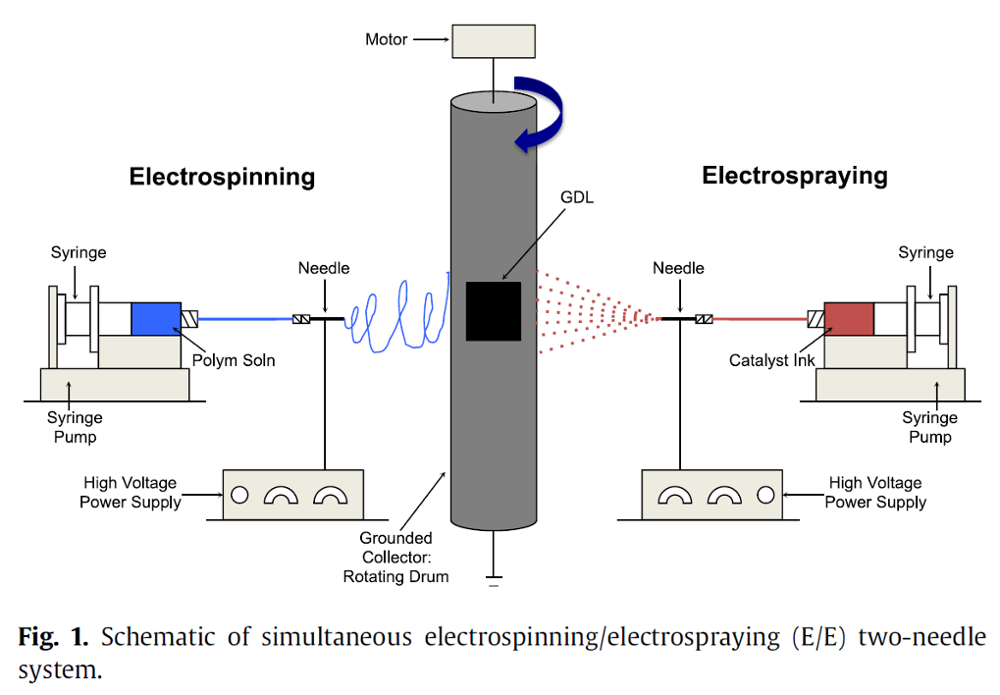

Hwang is working with Dr. Yossef Elabd, professor and associate department head in the Artie McFerrin Department of Chemical Engineering at Texas A&M, to develop a process for producing high-quality low platinum loading fuel cell electrodes in large quantities.

This process is in high demand, as fuel cell vehicles remain expensive to produce because of the cost of the platinum catalyst.”

“The purpose of this program is to really identify if there is a need for your technology on the consumer market, and if there is a need, what do people want to use your product for,” Hwang said. “The goal is to save to time in development by talking to consumers and seeing if the problem they need

Texas A&M is able to provide this opportunity to teams of engineers, such as Elabd and Hwang, through the National Science Foundation (NSF), who awarded an I-Corps Site grant to Texas A&M to support up to 150 undergraduate and graduate student teams who have innovative product solutions. The six-week program includes training participants in the foundational elements of product commercialization, access to travel funds to conduct potential industry and consumer interviews, and access to industry mentors.

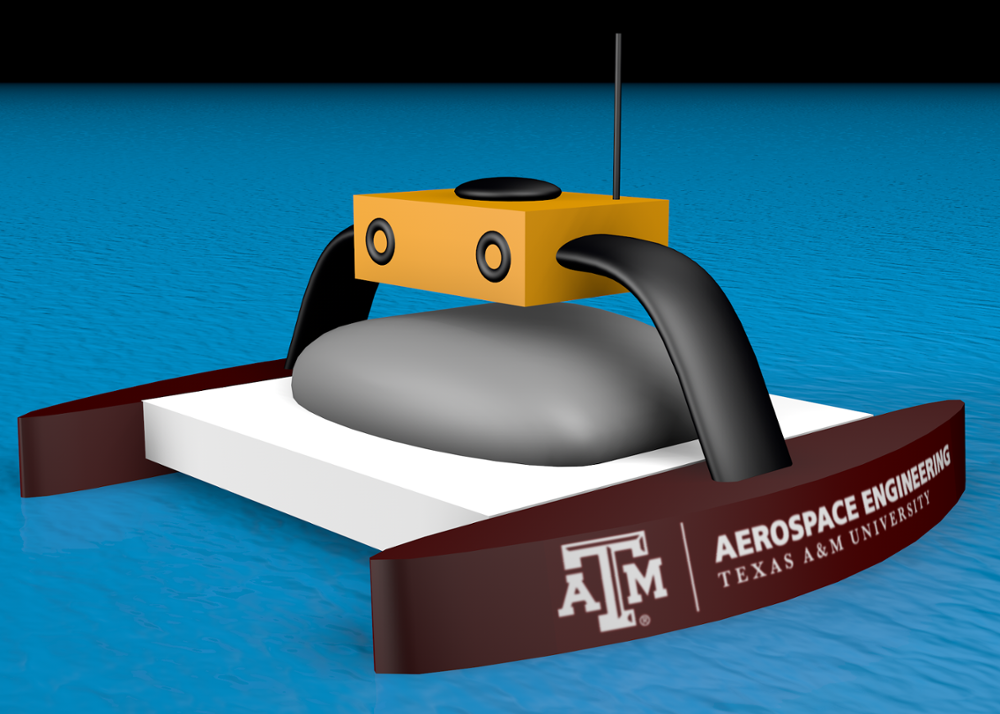

The program also provides engineers insight into additional uses for their product outside of what they originally considered. Aerospace engineering undergraduate student Gerardo Barillas and his technical advisor, Dr. Raktim Bhattacharya, an associate professor of in the Department of Aerospace Engineering at Texas A&M, are developing an aquatic drone that can take water samples and identify hazardous

“It was originally built for emergency responders so that they can identify hazardous chemicals in the water source if they were doing a rescue during an event, such as a

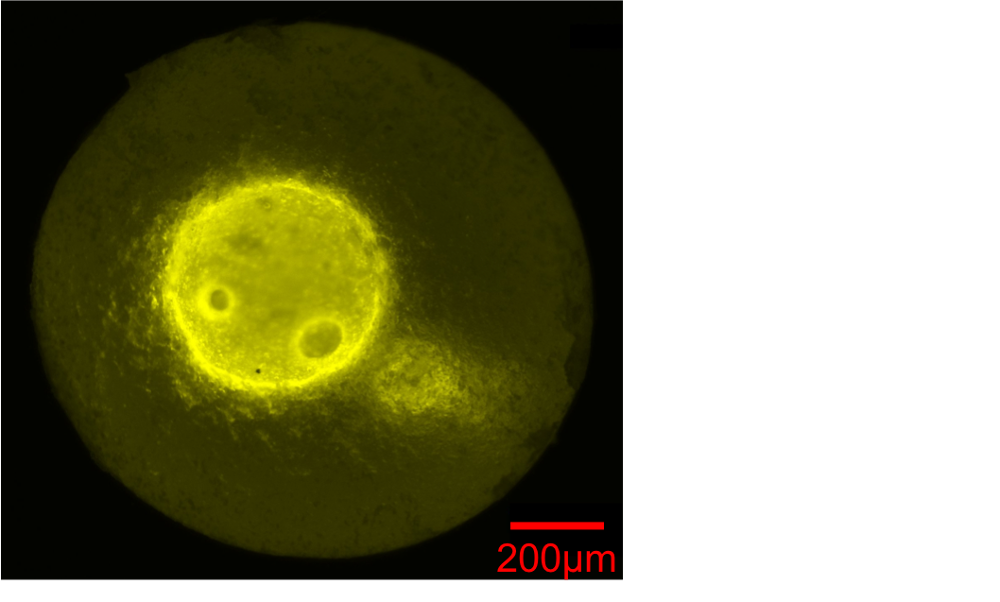

For some students, the experience reinforced the value of networking. Shreedevi Arun Kumar, a biomedical engineering doctoral student, is working with Dr. Corey J. Bishop, an assistant professor in the Department of Biomedical Engineering at Texas A&M, to develop innovative solutions for vaccine delivery in third world countries. Vaccine transport is costly and requires cold storage and careful handling to retain vaccine functionality, conditions that are not always easily present in areas such as remote desert communities, where vaccines are brought in on a Styrofoam cooler via camel. In response to this challenge, Kumar developed a drug delivery system that keeps the vaccine insulated within a bubble, isolating it from environmental factors and allowing it to remain viable.

“I found that understanding how you communicate and form relationships with potential customers is really important,” Arun Kumar said. “I think in a traditional engineering approach, you are very focused on ‘how do I make this product work?’ This program really put me out of my comfort zone in talking to consumers, but it also pushed me to get out there and ask questions and gave me entrepreneurial that you don’t normally get in school.”

For many students, the program has helped them realize not only the full potential of their product, but also themselves.

“This program really helped me identify what I like doing, which is research and development for products,” Hwang said. “I am still considering where my role will be, but I really like trying to form creative solutions for someone that has a certain problem, and I learned that as a part of this program.”

Students interested in more information on becoming an I-Site fellow can contact principal investigator Magda Lagoudas at m-lagoudas@tamu.edu or co-principal investigator; Rodney Boehm at rodneyboehm@tamu.edu.