Sam Noynaert, two applied drilling program graduate students and Fred Dupriest review rig data. |

Image: Nancy Luedke

One of the biggest drawbacks of drilling research is a university’s inability to have a state-of-the-art rig available to students for studying the physics of drilling operations. It is simply too expensive and risky for most academic budgets. Yet student researchers need this access to learn how to solve issues they are taught to identify in the advanced drilling classes at Texas A&M University.

Assistant professor Dr. Sam Noynaert and professor of engineering practice Fred Dupriest of the Harold Vance Department of Petroleum Engineering found a solution to this problem by directly involving their graduate students in actual field drilling operations through a program they developed called Applied Drilling Research (ADR).

ADR offers typically independent unconventional operators the chance to have the specific performance limiters in their drilling processes investigated. If the solution to the problem requires physics-based knowledge the drilling operation does not already have, a detailed ADR contract is drawn up to investigate, but only if the company involves the student researchers deeply in their daily operations. Through this cooperation, Noynaert, Dupriest and their students gain access to field data, specific well information, an experienced engineer involved in the project, and often the vendors of the drilling equipment the company uses.

Noynaert and Dupriest stress investigation and proper communication in their drilling classes because they noticed a reoccurring theme in unconventional reservoir drilling: not enough time was taken to understand anomalies and drilling limitations that kept occurring. This is because drilling operations are expected to stay within specific cost and time parameters, so drilling teams are encouraged to work around issues where possible. If a drilling team observes that certain rock formations always need an extra drill bit, that empirical lesson is passed down to other drilling teams as a known limitation and becomes standard practice.

Dupriest and Noynaert feel these accepted issues need to be investigated to determine if research can provide an answer that produces a better tool or technique for future drilling operations. Thanks to today’s technology, performance anomalies and limitations can be identified in every foot of holes drilled with a rig using remote access to high-speed digital data.

“I don’t need a rig out here in the backyard of Texas A&M,” said Dupriest. “With data available from a typical rig, with the subroutines I can run and the instruments I can place on that rig, I can get the same level of information I might be able to get from, to a large degree, a controlled environment at Texas A&M.”

The graduate student researchers in ADR view this as an incredible opportunity to work with actual operation data from real-time drilling using the best information possible. They expressed excitement to see tenets they learned in class come to life in a practical application.

“(The students) are focused on developing new knowledge, but they are doing that within the context of how it gets used and they are promising to deliver to that company a different way of drilling,” said Dupriest. “It’s a very different academic learning experience.”

The pace of a real-time drilling operation is a daunting challenge for the students, as the contract requires an 8 to 12 month, day-in, day-out effort. The professors evaluate morning rig reports and review data with the students. The students attend conference calls with company engineers, input information the operators provide, and analyze causes and effects until a solution is found.

“It’s like a normal project anywhere else out in the workplace,” said Noynaert. “You’re constantly re-evaluating and keeping up with it.”

Solutions are published by the student researchers so other companies can improve their operations. The information is also incorporated into the curriculum for both the undergraduate and graduate high-performance drilling classes at Texas A&M.

Assistant professor Dr. Sam Noynaert and professor of engineering practice Fred Dupriest of the Harold Vance Department of Petroleum Engineering found a solution to this problem by directly involving their graduate students in actual field drilling operations through a program they developed called Applied Drilling Research (ADR).

ADR offers typically independent unconventional operators the chance to have the specific performance limiters in their drilling processes investigated. If the solution to the problem requires physics-based knowledge the drilling operation does not already have, a detailed ADR contract is drawn up to investigate, but only if the company involves the student researchers deeply in their daily operations. Through this cooperation, Noynaert, Dupriest and their students gain access to field data, specific well information, an experienced engineer involved in the project, and often the vendors of the drilling equipment the company uses.

Noynaert and Dupriest stress investigation and proper communication in their drilling classes because they noticed a reoccurring theme in unconventional reservoir drilling: not enough time was taken to understand anomalies and drilling limitations that kept occurring. This is because drilling operations are expected to stay within specific cost and time parameters, so drilling teams are encouraged to work around issues where possible. If a drilling team observes that certain rock formations always need an extra drill bit, that empirical lesson is passed down to other drilling teams as a known limitation and becomes standard practice.

Dupriest and Noynaert feel these accepted issues need to be investigated to determine if research can provide an answer that produces a better tool or technique for future drilling operations. Thanks to today’s technology, performance anomalies and limitations can be identified in every foot of holes drilled with a rig using remote access to high-speed digital data.

“I don’t need a rig out here in the backyard of Texas A&M,” said Dupriest. “With data available from a typical rig, with the subroutines I can run and the instruments I can place on that rig, I can get the same level of information I might be able to get from, to a large degree, a controlled environment at Texas A&M.”

The graduate student researchers in ADR view this as an incredible opportunity to work with actual operation data from real-time drilling using the best information possible. They expressed excitement to see tenets they learned in class come to life in a practical application.

“(The students) are focused on developing new knowledge, but they are doing that within the context of how it gets used and they are promising to deliver to that company a different way of drilling,” said Dupriest. “It’s a very different academic learning experience.”

The pace of a real-time drilling operation is a daunting challenge for the students, as the contract requires an 8 to 12 month, day-in, day-out effort. The professors evaluate morning rig reports and review data with the students. The students attend conference calls with company engineers, input information the operators provide, and analyze causes and effects until a solution is found.

“It’s like a normal project anywhere else out in the workplace,” said Noynaert. “You’re constantly re-evaluating and keeping up with it.”

Solutions are published by the student researchers so other companies can improve their operations. The information is also incorporated into the curriculum for both the undergraduate and graduate high-performance drilling classes at Texas A&M.

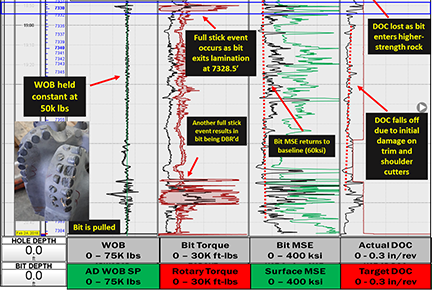

Drilling data from rig operation reveals clues to equipment performance. |

Image: Dr. Sam Noynaert

“In one case, the low drill rates and the need for two bits to drill a given interval was seen as normal, or even excellent performance,” said Dupriest. “Yet our discrete analysis of digital data and operating practices showed that stickslip in a few feet of interfacial severity was the sole cause of damage, and that the low drill rate was due more to bit whirl than rock hardness.”

In order to gain the most complete information needed, the companies also experience some academic learning. In the initial phase of an ADR project, Dupriest provides training on the physics of drilling mechanics, work flow, step tests and communications to get everyone in the drilling operation, from the decision-makers at the top to those who work the rig in the field, on the same page as the student researchers, who learn these critical processes in their classes.

“This comes back to academic training,” said Dupriest. “We should understand how things work and make decisions based on that. Every time we take a subject and do these ADRs, we dig and dig and peel away the layers of the onion and find something physically at some level that didn’t work the way we thought.”

Companies that have worked with ADR have had a change of heart about accepting empirically learned standard practices without question. Since their drilling teams are able to participate in the field research, collect the right data for ADR and communicate important observations to the students, workers are empowered with a sense of ownership in the process, and willingly accept the results and change the way they operate when they understand the benefits of the investigation. Both professors have noticed an increase in participation of experienced industry engineers in the distance learning certificate classes that teach these same investigative processes.

“From the sponsors’ perspective, it’s a simply extraordinary rate of return,” said Noynaert. “In a single well they’ll pay off the (contract investment in) ADR. In most cases, they’ll end up cutting the days per well by two or more. And those days are to be saved on each well drilled by each of their rigs going forward, which makes the return of investment effectively infinite. Financially, the program does not bring in millions but we don’t need millions. We just need to fund a few grad students.”

The students also experience an extraordinary rate of return, even the undergraduate students who only learn the ADR results through their coursework. By phasing out observational habits that work around limitations, and instead concentrating on solutions ferreted out by technology, data and research, this next generation of drilling engineers is better prepared to tackle the challenges future unconventional drilling reservoirs present.

“What we hope is when they graduate, not only will they walk out the door as confident drilling engineers, they also walk out with this unique understanding of how to get technology in the hole within an actual operating organization,” said Dupriest.

“We are, and want to remain, the place where if a company says, ‘We need a good drilling engineer,’ they should think, ‘We need to come to Texas A&M first and see if there’s any graduates we can hire,’” said Noynaert.

In order to gain the most complete information needed, the companies also experience some academic learning. In the initial phase of an ADR project, Dupriest provides training on the physics of drilling mechanics, work flow, step tests and communications to get everyone in the drilling operation, from the decision-makers at the top to those who work the rig in the field, on the same page as the student researchers, who learn these critical processes in their classes.

“This comes back to academic training,” said Dupriest. “We should understand how things work and make decisions based on that. Every time we take a subject and do these ADRs, we dig and dig and peel away the layers of the onion and find something physically at some level that didn’t work the way we thought.”

Companies that have worked with ADR have had a change of heart about accepting empirically learned standard practices without question. Since their drilling teams are able to participate in the field research, collect the right data for ADR and communicate important observations to the students, workers are empowered with a sense of ownership in the process, and willingly accept the results and change the way they operate when they understand the benefits of the investigation. Both professors have noticed an increase in participation of experienced industry engineers in the distance learning certificate classes that teach these same investigative processes.

“From the sponsors’ perspective, it’s a simply extraordinary rate of return,” said Noynaert. “In a single well they’ll pay off the (contract investment in) ADR. In most cases, they’ll end up cutting the days per well by two or more. And those days are to be saved on each well drilled by each of their rigs going forward, which makes the return of investment effectively infinite. Financially, the program does not bring in millions but we don’t need millions. We just need to fund a few grad students.”

The students also experience an extraordinary rate of return, even the undergraduate students who only learn the ADR results through their coursework. By phasing out observational habits that work around limitations, and instead concentrating on solutions ferreted out by technology, data and research, this next generation of drilling engineers is better prepared to tackle the challenges future unconventional drilling reservoirs present.

“What we hope is when they graduate, not only will they walk out the door as confident drilling engineers, they also walk out with this unique understanding of how to get technology in the hole within an actual operating organization,” said Dupriest.

“We are, and want to remain, the place where if a company says, ‘We need a good drilling engineer,’ they should think, ‘We need to come to Texas A&M first and see if there’s any graduates we can hire,’” said Noynaert.