Researchers at Texas A&M University and the Stevens Institute of Technology are laying the groundwork to develop the next generation of biomedical materials used to treat chronic wounds.

Research partners Dr. Svetlana Sukhishvili and Dr. Hongjun Wang conceived the project during a meeting regarding their groups’ primary focus of research. Experiments were conducted at both facilities, and the results of each were combined to form one cohesive study. Both are researchers funded by the National Science Foundation and the National Institutes of Health, respectively.

The findings from this study provide an important stepping stone for developing smarter skin grafts that can help facilitate wound healing while minimizing infection for those hard to heal skin wounds.

“Our group has expertise in developing new polymers and functional surface assemblies for biomedical applications,” said Sukhishvili, professor and director of the soft matter facility at Texas A&M.

“The findings from this study provide an important stepping stone for developing smarter skin grafts that can help facilitate wound healing while minimizing infection for those hard to heal skin wounds,” added Wang, professor and chair of the Department of Biomedical Engineering at Stevens Institute of Technology.

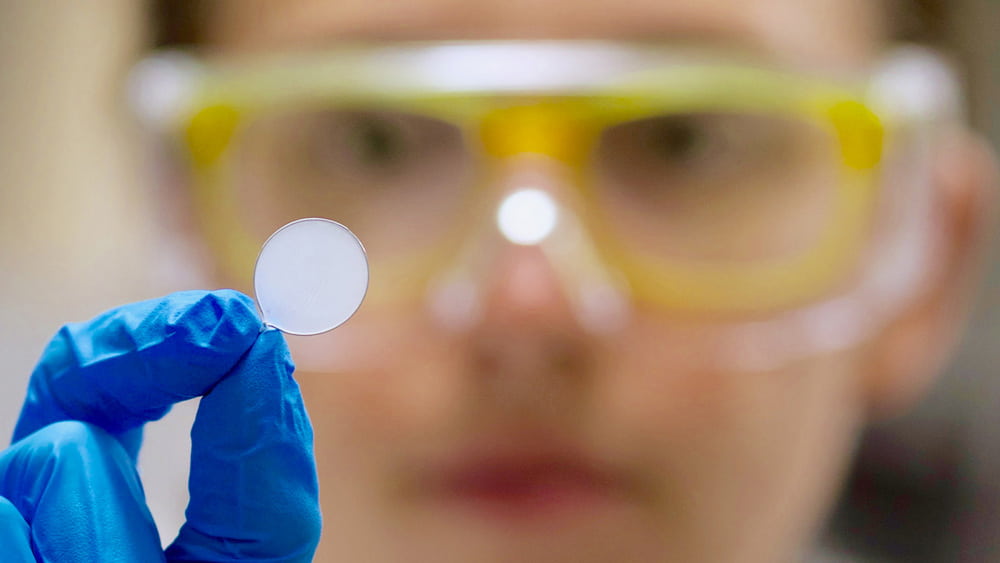

“At Texas A&M we investigated how to build a stimuli-responsive polymeric material that could absorb and release antibiotics when prompted by a physiologically relevant stimuli,” explained Victoria Albright, graduate student and lead researcher in the Department of Materials Science and Engineering at Texas A&M.

The team’s solution was to add functional containers, or micelles, on the surface of biodegradable fiber meshes to enhance surface functionality.

“Once we had a working system, we then sought to understand how this material would interact with bacteria and found it would be able to prevent infection as desired,” Albright said.

This important advance demonstrates the benefits of bringing together creative approaches from polymer science and biomaterials. It also illustrates the breadth of NSF’s mission, which is not only ‘to promote the progress of science’ but also ‘to advance the national health’.

Wang and his team studied the interaction of human cells with the material. They found that the material was not only nontoxic but also enhanced cellular growth and migration due to the surface-bound micelles, which changed the surface topography or texture.

This study demonstrates how important the engineering of specific surface structures and functionalization, or changing the surface chemistry, is for designing advanced biomaterial and controlling interactions of living matter with artificial materials.

“This important advance demonstrates the benefits of bringing together creative approaches from polymer science and biomaterials," said Andrew Lovinger, one of the National Science Foundation (NSF) program officers who helped fund this work. "It also illustrates the breadth of NSF’s mission, which is not only ‘to promote the progress of science’ but also ‘to advance the national health’.”

Simply put, the team created new polymer materials that can be used to coat wounds with previously unachievable properties, virtually turning the surfaces of skin grafts into highly functional ones.

“The material we designed could potentially be used for advanced wound dressings,” Albright concluded. “These materials would have the highest impact in hard-to-heal wound cases such as those for diabetic ulcers and chronic wounds.”

"Now that we have shown very promising 'in vitro' results with human cells, the next critical step for the team is to further demonstrate this concept via 'in vivo' testing,” said Wang. “Next the team will work closely with clinicians to optimize our design, maximize benefits for patients, and enhance the real-world applicability of the skin graft. The team will continue to engineer the skin graft to specifically address different types of wounds and to further personalize it for different patients."

The researchers plan to continue working together to further develop this and similar materials as part of their long-term collaboration.

The research team’s findings were electronically published on the cover of Advanced Healthcare Materials and featured in Advanced Science News.