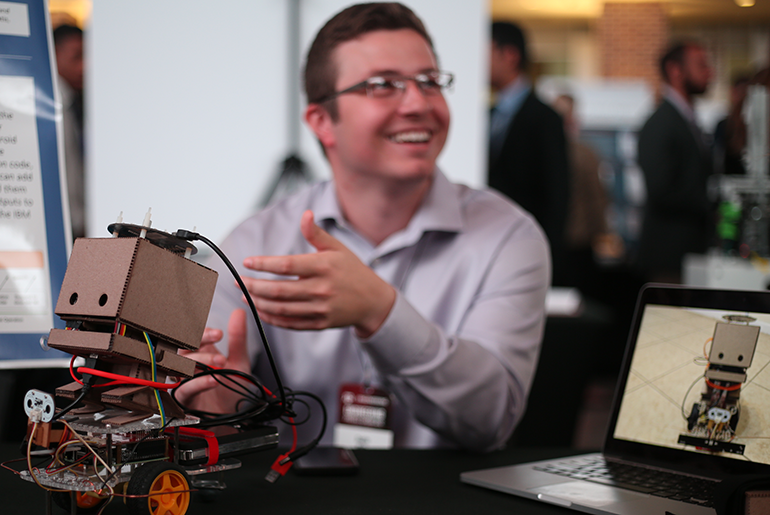

Kyle Field’s Hall of Champions was packed for the sixth annual Engineering Project Showcase, the annual celebration of the technical accomplishments of Texas A&M University’s engineering undergraduate students.

More than 200 teams with freshmen to seniors across all engineering departments participated and presented their team projects, through posters and prototypes, to industry judges in competition for top awards.

While not mandatory, a great deal of the projects at showcase this year relied on functioning prototypes to demonstrate their progress and mastery of the need statement they chose to answer. The student team behind the low-cost field-use nystagmus (F.U.N.) recorder demonstrated their goggles, much to the delight of showcase attendees. While the ultimate purpose of the goggles is to assist law enforcement in the conviction of DUIs by recording rapid eye movement, the demonstrator entertained the crowd with over-enlarged eyes from magnifying glasses.

“People will be charged but not convicted because a lot of evidence is thrown out,” said Christopher Vega, biomedical engineering senior. “These will record the eyes, illuminate them and make it a lot more constant so that in a court of law the evidence is fully admissible and it can actually assist in getting a drunk driver off the streets and keeping the streets a lot safer.”

The students worked with the local sheriff’s department, as well as a local ear, nose and throat physician. When the biomedical engineering department was presented with the conviction challenge, as well as the overall hopes for an end result, the student team came up with the F.U.N. goggles.

The mechanical engineering student team that took second place in their category with a document preservation tool had a very positive experience with their sponsor, the Texas A&M University Libraries. The team worked to help the library staff preserve historical document integrity from oils, environmental influences and moisture. They created a welding encapsulator that uses ultrasonic energy to create a seam or spot weld around a document or item.

The mechanical engineering student team that took second place in their category with a document preservation tool had a very positive experience with their sponsor, the Texas A&M University Libraries. The team worked to help the library staff preserve historical document integrity from oils, environmental influences and moisture. They created a welding encapsulator that uses ultrasonic energy to create a seam or spot weld around a document or item.

“Showcase has been awesome in that I’ve never seen so many engineering students work so hard on a project,” said Sheila Khodadad, mechanical engineering senior. “A lot of us didn’t have any experience coming into this. Then you get this new idea and you’re trying to figure out how to solve this problem. It’s just really worthwhile, learning how to problem solve in real life. Seeing a design all the way to development is just a really good feeling. You work so hard with your teammates and it’s been amazing.”

Industry judges were impressed with this year’s projects. Many found themselves interacting with the teams beyond those they were asked to judge, simply because the projects were so impactful. Many of the industry judges had participated in the past, citing the interesting and unique projects as a main cause for returning. Originally from Mexico, Jose Quintana ’86, president of Advent GX, came to study computer science at Texas A&M and ended up staying in the area for work. This was his second year to judge for the showcase.

“These are technologies that contribute to the betterment of our community,” said Jose Quintana ‘86, president of Advent GX. “Even judging the freshman students with their marble-sorting technology is great to see. [Showcase] gives us the opportunity to see the kids at work, have them go through a process where they have to manage their teams and the design process itself.”

Judges and visitors aren’t the only ones to benefit from the team project experience. As Roger Kittrell ’86, sector leader in transportation with the Wood Group, pointed out, the students gain skills outside of the classroom that polish them as a potential hire.

“My son is a sophomore electrical engineer,” said Kittrell. “I told him that once he graduates, all you are going to have is one sheet of white paper that represents all you’ve done. They aren’t going to know anything about you except what’s on that one sheet of paper and by talking to you. You’ve got to get as much experience as possible. The projects allow students to interact as a group, just like a work environment, where they would have a problem that needed to be solved and collaborate on solving it together.”

The interaction and communication skills gained through team interaction is a large part of why showcase participants enjoyed it. Because few engineering industries have individual work scenarios, students learning to collaborate and communicate in a real-world environment helps round them out.

“Ensuring the showcase happens annually is very important to me,” said Magda Lagoudas, executive director of Industry and Nonprofit Partnerships for the College of Engineering. “I know these students benefit immensely from the experience of interacting with industry and the journey to getting their projects and themselves ready for the judges. We are extremely grateful for industry involvement each year, especially as our showcase grows larger to accommodate more majors and more diversity in projects.”

This event was made possible by the 2018 Engineering Project Showcase sponsors and supporters: Kubota, Texas A&M Engineering Experiment Station, Baker Hughes, Boeing, Elbit Systems of America, Emerson, Houston Airports, Peak Nano, student project sponsors, industry judges, and support staff and faculty.

Winners of of the 2018 Engineering Project Showcase:

Biological and Agricultural Engineering Capstone Design winners:

Kubota Tractor Corporation Award: Sasle, Nicaragua Water Conveyance and Distribution System

Second place: Controlled Atmosphere Storage

Biomedical Engineering Capstone Design winner:

Development of a Non-Blood Contacting Pediatric Heart Augmentation Device

Various Department Capstone Design winner:

CommBo: Modernizing Augmentative and Alternative Communication

Electrical & Computer Engineering Capstone Design winner:

Elbit Systems of America Award: East Texas Climate Tracking

Engineering Technology & Industrial Distribution Capstone Design winners:

Emerson Award: NASA Class-1E Facility Monitoring and Control System

Second place: Mobility Worldwide

Industrial & Systems Engineering Capstone Design winners:

Houston Airport System Award: Autonomy as a Service: The Optimal Experience

Second place: Revitalizing American Manufacturing with Lean Practices

Mechanical Engineering Capstone Design winners:

Kubota Tractor Corporation Award: Shredder for Recycling Plastics

Second place: Texas A&M University Libraries Document Encapsulator Project

AggiE_Challenge winners:

The Boeing Company Award: EcoMold

Second place: Advanced Vapor Compressor Desalination (Desalination & Power Team)

Design Competition winners:

Baker Hughes, a GE Company Award: Marlin AUV

TEES Commercialization Award:

Smart Harness System: The Future of Fall Protection | Mechanical Engineering Capstone Design Team

Non-Capstone, other course project winner:

Lazarus Specialty Ammunition

ENGR 112 winners:

Team 9

Team 5