A significant amount of U.S. domestic oil production comes from shale. Extracting oil and gas from these unconventional reservoirs normally requires drilling horizontal wells and using hydraulic fracturing techniques. Yet predicting the full effect of these techniques is still uncertain because the understanding of how fluid flows through shale is still evolving.

Dr. David Schechter’s research group has developed a new type of simulator that better illustrates and predicts the effects of these techniques. This robust simulator draws on data from laboratory experiments and combines it with known geologic data on fractures. Then it uses unstructured gridding and newly developed coding to create models that improve the understanding of:

- how fractures affect reservoir flow

- how fracturing fluids with added surfactants (soaps) affect oil recovery

- which enhanced oil recovery processes are best for different reservoir situations

In addition to improving understanding, the research group used this data and these models to challenge current theories on fluid retention in reservoirs.

Fractures affect flow

Schechter, an associate professor and the Aghorn Energy Career Development Professor in the Harold Vance Department of Petroleum Engineering at Texas A&M University, is no stranger to fractures. His research interests cover geological and petrophysical analysis, and he is quick to explain fracture fundamentals.

“Fractures are not necessarily chaotic in reservoir rocks,” said Schechter. “If you know the rules of rock mechanics, and you study outcrops on the surface and the subsurface with downhole tools, then you can generate fracture networks based on certain known rules. Some fractures are well-behaved regarding fracture spacing and length, some aren’t and some are irregularly spaced. If we have enough core data, if we understand rock mechanics and the stresses the basin has undergone, then the resulting fracture patterns usually adhere to simple rules.”

Aerial photo of surface outcrop features in the San Juan Basin

Water flows in surface fractures on rock outcrops. This attracts vegetation, as shown in the aerial photo (courtesy of John Lorenz). In the subsurface, similar fracture patterns allow the transport and production of oil. Geologists map surface outcrops of rock with scan lines, creating maps of fracture patterns in liquid-bearing formations. Schechter’s group converts these maps into reservoir simulation grids using a technique called unstructured gridding. In this technique, fractures are represented with complex polygonal grids, not the simple straight-lined Cartesian grids most software uses.

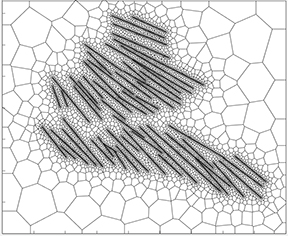

Image of unstructured gridding detailing fracture properties

One student, Jianlei Sun, wrote a code that converts fracture patterns and unstructured grids into sophisticated simulation grid systems. The code contains properties of interest needed by the simulator, such as fracture strike and direction, crack size, and the length and height of the fracture.

Other ways fluid movesSchechter’s simulator goes beyond modeling fracture properties, it also deals with fluid properties. The oil flow in shale reservoirs is hard to predict because the rock has extremely low permeability due to microscopic pores. Extracting oil from this tight rock is done by transport mechanisms, such as wettability alteration to improve capillary imbibition.

Schechter’s labs specialize in studying wettability and imbibition in rocks. Wettability is the ability of a fluid to maintain contact with a rock surface and not be repelled by it. Imbibition is the ability of the rock to absorb fracture fluids, such as water mixed with surfactants. These fluids repel and displace oil within the rock pores so the oil can be recovered. Without changing or altering wettability, capillary imbibition might not happen.

“If water is repelled from the surface, it won’t move into the rock,” said Schechter. “But if water is attracted to the surface, it will pull water in, replacing oil saturated pores due to capillary imbibition. Maybe you’ve taken a sugar cube and touched it to coffee? A sugar cube is saturated with air (between the sugar crystals) but the surface of the sugar cube prefers to be wetted by water or coffee as opposed to air. When you touch it to the coffee surface and it sucks up that coffee, that’s capillary imbibition. We’re looking at improving oil recovery with surfactants, which depend on liquid/liquid imbibition. That’s why we study contact angles.”

Schechter’s group studies the effects of different chemical mixtures in fracture fluids. They are looking for mixtures that change the wettability of rock from oil-wet to water-wet, allowing the fluid to penetrate oil-filled rock in laboratory settings. The experiments help researchers understand and map the outcomes of contact angles. They use a CT scanner to confirm the results and then transfer this information to their simulator.

These two videos illustrate how important contact angles are in a liquid to liquid exchange.

Video one shows a drop of crude oil on a needle touching the surface of shale rock. The contact angle is less than 90 degrees so the oil adheres to the surface. This means the oil within the shale rock attracts more oil, so it is oil-wet.

Video two shows a shale rock imbibed with a surfactant solution of water and soap. The contact angle of the drop of oil touching its surface is greater than 90 degrees so the oil is repelled, meaning this rock is water-wet.

Fluid retention in unconventional reservoirs is beneficial“The unconventional revolution is so surprising,” said Schechter. “We can take a conventional plug of porous rock, such as sandstone, and we can pump fluids in it. Under pressure, we can inject oil or water through it with ease. The unconventional rocks we are studying, such as shale, are so tight we can’t pump anything into them. However, when we expose them to surfactants that alter the wettability, spontaneous imbibition occurs, thereby transporting the aqueous phase into the rock at surprisingly rapid rates.”

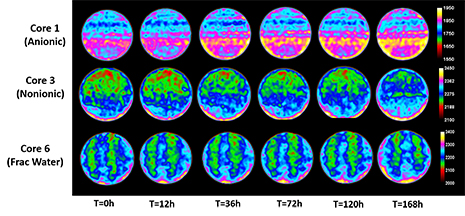

In the past, companies injected water and sand (or proppant) in conventional reservoir wells under high pressure to create fractures. It was thought that recovering most of the water (flowback) was beneficial so water would not block the outward flow of oil. Schechter’s experiments on unconventional rocks prove that nonporous rocks behave differently. Samples saturated with oil were exposed to water imbued with surfactants. CT scans measuring density revealed the less-dense oil was replaced by the denser water mixes through imbibition. Fractures then allowed the oil to flow out.

“We found that you want the reservoir to keep that water,” said Schechter. “It’s counterintuitive. It’s breaking old practices. Before it was assumed if water penetrates the formation, then it will block the oil flow, thereby reducing well productivity. What we’re finding is if water penetrates in by capillary imbibition and you get very little water back, the implication is the aqueous phase has imbibed into the rock and displaced oil into the fractures and that’s actually a good thing.”

CT scans illustrating fluid displacement

Improved predictions benefit industryThrough the use of chemistry, mathematics and physics, Schechter’s group has developed a tool that better illustrates and maximizes well production for shale reservoirs. Their simulator has created more robust predictions than current simulators because it is based on comprehensive data. This helps industry reduce unneeded operation costs by helping engineers better understand how unconventional rock behaves after specific fracturing treatments.

“Basically that’s what I study, that this rock is full of oil, but it is amazing that oil comes out of this rock because it’s so tight,” said Schechter. “Industry is interested in the improvement of recovery, whether by injecting aqueous phase with surfactants or gas injection, and we investigate all forms of enhanced recovery. We can predict what’s going to happen. We can scale up our simulator to reservoir dimensions and quantify the improvement.”