Advanced reactor technologies have generated interest for their potential to reduce fossil fuel emissions, improve energy efficiency and cut down on nuclear waste. Researchers with the Department of Nuclear Engineering at Texas A&M University have provided new insights into the workings of an advanced sodium-cooled fast reactor fuel assembly, having used a specialized test facility to measure hydraulic parameters and validate computational tools used in reactor design and testing. The fast reactor assembly design used is significant, not only because of the complex inner knowledge it can provide about advanced reactors, but also because the Texas A&M experiment is using the largest transparent test fuel assembly of its kind to date.

Advanced reactor technologies have generated interest for their potential to reduce fossil fuel emissions, improve energy efficiency and cut down on nuclear waste. Researchers with the Department of Nuclear Engineering at Texas A&M University have provided new insights into the workings of an advanced sodium-cooled fast reactor fuel assembly, having used a specialized test facility to measure hydraulic parameters and validate computational tools used in reactor design and testing. The fast reactor assembly design used is significant, not only because of the complex inner knowledge it can provide about advanced reactors, but also because the Texas A&M experiment is using the largest transparent test fuel assembly of its kind to date.

“TerraPower, AREVA and Argonne National Laboratories (ANL) have a strong interest in this new fuel design that will be potentially used in advanced fast reactors,” said Dr. Rodolfo Vaghetto, a research assistant professor with the department and project investigator. “This research is part of the work we do to ensure a new design goes from conceptual to something that you can actually build, operate safely and use to produce clean energy in an efficient way. The high-fidelity experimental data we’ve gathered through this experiment will help improve advanced simulator capabilities and validate state-of-the-art computational codes.”

Fuel assemblies help facilitate the process of power generation in the reactor through fission, a process by which an atom splits and a small amount of mass is converted to energy. In comparison to current reactors, advanced fast reactors produce “fast” neutrons that are not as efficient at creating fission, but are readily received by a specific uranium isotope to become plutonium. Producing the plutonium in this manner gives these conceptual reactors the potential to produce more nuclear fuel than they use, leading to a more efficient, abundant and clean production of energy to meet public needs. While the test assembly is unique in that it is the largest of its kind ever constructed, the researchers have also ensured the measurements taken are accurate through a novel technique, a transparent assembly.

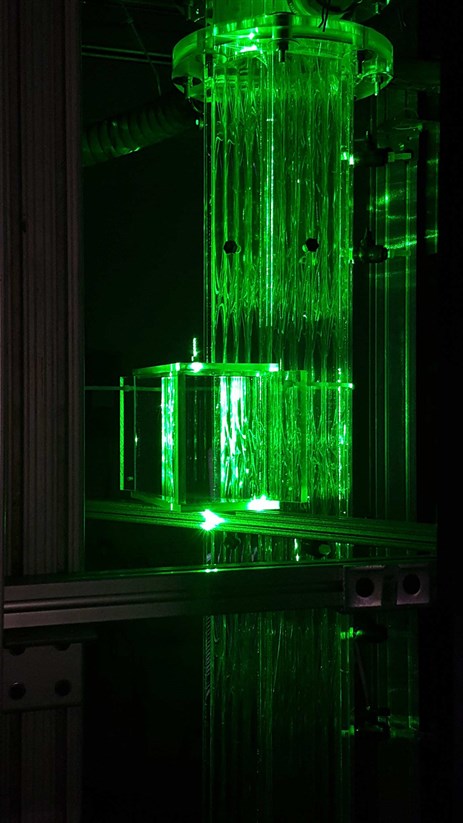

“Typical test assemblies are encapsulated in a stainless-steel container so you can’t see what’s going on,” Vaghetto said. “We made this assembly in acrylic so we can watch the processes and apply state-of-the-art techniques to measure full-field velocities at different locations inside the test bundle and pressure drops, something that has never been done before at this level of accuracy. That experimental data is then used by other members of this project, like TerraPower and ANL, to compare with their simulations of the assembly on the computational side and validate those tools.”

The project was established in 2015 and is managed by nuclear utility company AREVA (subcontracted through the Department of Energy (DOE)) in partnership with ANL, Texas A&M and TerraPower, the nuclear energy tech conglomerate led by Bill Gates. AREVA’s interest in the project lies in improving advanced reactor technology, which requires accurate analyses of advanced fuel assemblies. In the interest of taking the most accurate measurements possible, the researchers used a specialized fluid that has the same index of refraction as the acrylic of the assembly. They then inject the solution with a fluorescent dye and other seeding particles and expose it to a laser to obtain high-resolution measurements. In their efforts to produce these high-quality measurements, the team had to deal with many challenges.

“We had to find all the right vendors in addition to all the optical testing that we had to do to choose the acrylic the assembly was made of,” Vaghetto said.

The next step for the Texas A&M research team will be to continue experiments on the assembly for further developments, analyzing experimental data and collecting new data using the existing test assembly in partnership with other national and international collaborators.

“There is a lot of interest in this type of geometry design for advanced fast reactors,” Vaghetto said. “This assembly seems to be the number one fuel design right now, and these companies are looking forward in meeting their interests in performing these analyses. Because of the interest in this we’re hoping to get the chance to work on future projects with this assembly.”

This research project was a collaborative effort within the Thermal Hydraulics Laboratory at Texas A&M, including Dr. Yassin Hassan, department head and Sallie & Don Davis ‘61 Professor in nuclear engineering, and research assistant professors Dr. Thien Nguyen, Dr. Rodolfo Vaghetto and Dr. Saya Lee. Nuclear engineering graduate students Nolan Goth, Mason Childs and mechanical engineering graduate student Philip Jones actively worked on this project as part of their research for their doctoral and master’s degrees. More than 15 undergraduate students also were instrumental in the success of this project.

This project is part of a DOE sponsored project, “Toward a Longer Life Core: Thermal Hydraulic CFD Simulations and Experimental Investigation of Deformed Fuel Assemblies.”