Before the Industrial Revolution, custom products were handmade by highly skilled individuals. Basic products that most people have in their homes today were very expensive and considered luxuries because of the time and skill that it took to make just one. What the Industrial Revolution brought about was the ability to mass-produce identical items. The result? Millions of units of a single product could be manufactured in short amount of time, increasing availability and reducing the cost for consumers.

Researchers from the Department of Mechanical Engineering and Department of Visualization at Texas A&M University want to take things even further, with custom cyber manufacturing, using the technology behind origami and kirigami manufacturing. The goal is to give non-manufacturers the ability to design and customize products such as chairs, lamps and desks for their own use.

Researchers from the Department of Mechanical Engineering and Department of Visualization at Texas A&M University want to take things even further, with custom cyber manufacturing, using the technology behind origami and kirigami manufacturing. The goal is to give non-manufacturers the ability to design and customize products such as chairs, lamps and desks for their own use.

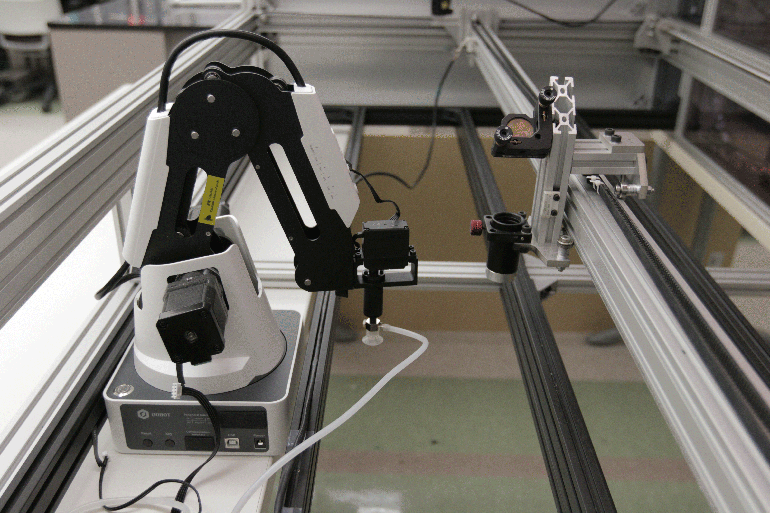

When one hears the word origami the first thing that usually comes to mind is an ornate figure made out of a single sheet of paper that has been folded many times. Origami manufacturing consists of the same basic idea. Manufacturers start by placing a flat sheet of material (metal or some kind of polymer) in a machine containing a robot that can fold it into the desired shape. Some machines can fold material using gravity, twisting and turning it so it bends in a specific direction. A kirigami machine has the ability to cut and fold the material. This is currently done for a select number of large-scale parts but has not yet been used to make commercial items for the public.

“It enables regular people to take their ideas and make something customized that’s as good as what they would get if they bought it in a store,” said Dr. Arun Srinivasa, co-director of the Institute for Manufacturing Systems and associate department head and Holdredge/Paul Professor in mechanical engineering at Texas A&M.

This type of technology is most needed in the field of orthotics, such as leg and wrist braces. Mass-produced braces are made the same way and not customized to fit each individual patient, which can make them extremely uncomfortable to wear. With custom cyber manufacturing, uncomfortable braces would no longer be an issue because patients could have braces molded to fit the shape of their wrists or legs. This type of technology has the potential to make commercial consumer items like jewelry, lamp shades, boxes or anything that is hollow or shell like.

In addition to its versatility, custom cyber manufacturing can also help open up employment in the manufacturing field. According to Srinivasa, a cyber manufacturing job will allow the person operating the machine to design what their product will look like. The merging of technology and creativity will not only appeal to engineers, but also non-engineers as well. Custom cyber manufacturing also frees up the machine operator from mundane tasks like cutting and folding since the machine has the ability to notify them when the object has been folded perfectly.

Some may ask, “Why go through all of this? Can’t you accomplish the same thing with 3-D printing?” The answer is no. 3-D printing and origami manufacturing are very similar, yet each has its own capabilities and strengths. For example, 3-D printing would not be the best way to make custom products we use on a daily basis that are thin and shell-like. Objects made in a 3-D printer are deposited from power and the end product is solid. They are very versatile, and can potentially make many intricate shapes but are slow and have difficulty with slender or thing parts. Origami manufacturing is also efficient, faster and costs a great deal less. Where a 3-D printer can take nearly three hours to make a single object, an origami manufacturing printer can take three minutes to make the same object.

Researchers are in the process of building a large origami manufacturing machine, which will be housed on the Texas A&M campus, with a robotic arm inside to fold the material.

“My dad was a machinist and could see that the other machinists would make amazing toys with scrap metal that was left over in their free time. I never used to buy toys when I was young because my dad’s friends would make toys for me,” said Srinivasa. “If we are able to provide that kind of thing to people, it will unleash their creativity.”