Students from the Department of Mechanical Engineering at Texas A&M University collaborated with a student from the Harold Vance Department of Petroleum Engineering to develop a new way to fight clean water access issues facing the world today.

With over 700 million people currently suffering from inconsistent access to clean drinking water, Coleman Fincher and his team saw the need for consumers to be reached almost anywhere.

Previous research achieved a low-cost solution with technical simplicity; however, these solutions are not accessible by consumers everywhere. The team hopes its project, the NanoWell, will provide a solution to accessibility problems while remaining inexpensive.

“We believed that we could render a design that maintains simplicity and low-cost and meet the challenges for consistency while remaining user friendly,” explained Fincher, a junior mechanical engineering student and the team leader. “Our design draws inspiration from plants, which use capillary action to draw water through their roots.”

Similar to the functions of a plant, the idea was modeled after a leaf with high surface area. This allowed the team to design a condenser 10 times smaller than those produced by earlier researchers.

“The NanoWell, has a dew collection surface or collection leaf, woven from hollow microfibers,” Fincher said. “By stacking these collection leaves, we can obtain a large amount of dew collection with an area slightly smaller than a standard drum.”

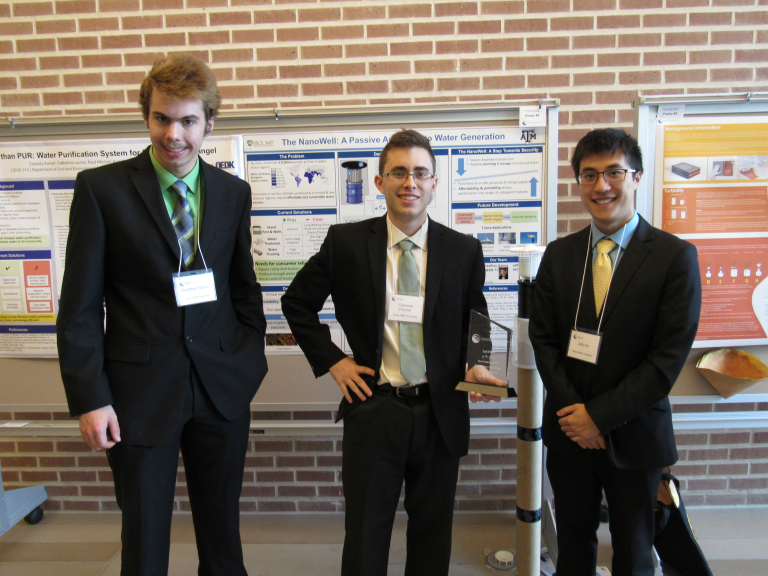

Geoffrey Garner, a junior mechanical engineering student, and Jeffy Ho, a junior petroleum engineering student, have worked with Fincher for the last several months.

“Our overall goal is to provide safe drinking water to Residents, particularly those in remote and low-resource regions,” Fincher said. “We hope to act as a stepping stone toward solving water insecurity.”

The team worked with Dr. Tanil Ozkan, visiting assistant professor in the Department of Mechanical Engineering, to develop a prototype of its project.

“This entire concept is the brainchild of Fincher,” Ozkan said. “Since my graduate research has also been on polymer nanocomposites, I immediately noticed the immense potential of the project pursued by the group.”

When the time came to develop a prototype, the team used the new 3-D Printing Lab in the Department of Mechanical Engineering. Students are encouraged to use their innovation and technical creativity to develop products to the furthest possible extent.

“With the opening of the 3-D printing studio, the entire student body has the opportunity for many success stories, like Coleman and his team, through the creative means provided during their engineering education,” Ozkan said.

The team earned second place with the NanoWell prototype at the Global Water Technologies Competition earlier this month.

“The competition and the award our students received are very prestigious,” Ozkan said.

The competition was held for the first time this year and was hosted by the National Science Foundation at Rice University. The students competed against 17 other teams from 13 universities across the United States.

“For this particular competition, we submitted an initial abstract and design video,” Fincher said. “Upon participating in the finals at Rice University, we presented a technical poster and pitch to judges from academia and industry.”

Teams were judged on their ability to explain the water challenge their submission seeks to address and on the technical and social feasibility of their proposed solution.

“For us, receiving the in person feedback from experts in affordable water systems and in water distribution was invaluable,” Fincher said. “The pragmatic insight provided by the judges based upon their experience was invaluable.”

Fincher and his team is also participating in the Shell Ideas 360 contest with this idea and has already made it to the second stage of the contest. The team hopes to continue to the final stage in London this summer.