More than a dozen nuclear engineering students from Texas A&M University presented at the 2016 American Nuclear Society (ANS) Student Conference in Madison, Wisconsin. Doctoral student Lane Carasik received the designation of best presentation in the graduate category for the thermal hydraulics research track. Carasik’s paper was “Turbulence Model Study for Pressure and Velocity Distributions for Molten Salts in a Cross-Flow Tube Bundle,” and detailed his research to develop a methodology to solve for pressure drops inside compact crossflow heat exchangers meant for molten salt reactor application.

More than a dozen nuclear engineering students from Texas A&M University presented at the 2016 American Nuclear Society (ANS) Student Conference in Madison, Wisconsin. Doctoral student Lane Carasik received the designation of best presentation in the graduate category for the thermal hydraulics research track. Carasik’s paper was “Turbulence Model Study for Pressure and Velocity Distributions for Molten Salts in a Cross-Flow Tube Bundle,” and detailed his research to develop a methodology to solve for pressure drops inside compact crossflow heat exchangers meant for molten salt reactor application.

The pressure drop determines the sizing or wattage of the pumps to implement in the reactor design. In the case of molten salts, the material can be highly corrosive and can require special pump designs. When Carasik initially investigated heat exchanger designs for molten salt reactors applications, he found that there was very limited data or no discernable methodology for determining crossflow pressure drops. To solve this problem, he decided to develop a methodology using a simplified computational analysis.

“The hope is that someone in the future will look at this methodology and find it useful,” Carasik said. “The idea behind it is that someone can utilize this work while developing a reactor design. Specifically, determining what a cautious estimate of the pressure drop inside a heat exchanger for that reactor would be.”

Carasik’s work draws inspiration from an Oak Ridge National Lab small modular advanced high temperature reactor design. In the design he is investigating, the geometry of the reactor has certain size constraints that influence the design parameters of the heat exchanger. Specifically, the size constrains both the arrangement (or direction) by which the fluid passes over the tubes and the size of the heat exchanger. With these design constraints in mind, Carasik had to look at a way to determine the pressure drops in the proposed heat exchangers.

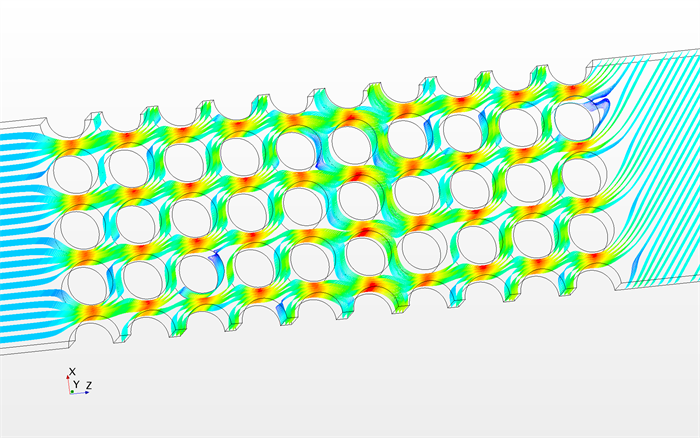

Above: the flowpath inside a heat exchanger

Carasik has pursued this research on molten salt reactor heat exchangers apart from his regular graduate research primarily because of his interest in furthering the development of molten salt reactors. According to Carasik, they can provide an economical and cost effective energy source for a variety of situations. Molten salt reactors and other reactor types had their development scaled back in the 1970’s in favor of light water reactors (LWR), which led to the development and use of pressurized water reactors (PWR), a type of LWR that was developed and is currently used by the U.S. Navy. Since the commercial nuclear energy program was born out of the Navy’s nuclear program in conjunction with the Atomic Energy Commission, LWRs became the standard reactor type in the U.S. and around the world. One of the appeals of molten salt reactors to Carasik is the large amount of start-up companies working towards bringing this technology to market.

“We’ve already built them before and we’ve proven that they work, it’s just a matter of what technology we need to develop to put them on the commercial market,” Carasik said. “LWRs are perfectly good machines, they are the backbone of our largest portion of clean energy output in this country and we should keep producing them, but we should always strive for improvements and innovations.”

However, according to Carasik nuclear industry groups may be hesitant to be the first to focus on this technology because costs cannot yet be ironed out from a regulatory side, which may constitute an economic risk. In contrast, Carasik does note that the potential economic and energy efficiency gains from capital costs and higher operating temperatures outweigh that risk.

According to Carasik, higher operating temperatures allow for higher energy efficient turbines to be utilized and can reduce the overall size of the reactor.

“For example, if I have a 1,000 megawatt electric power plant, an LWR could be at least 30 percent larger in terms of physical size than a molten salt reactor of the same wattage,” Carasik said. “That translates to lower cost from construction materials to produce the reactor but with the same energy output being created more efficiently.”

According to Carasik, with any solution there are drawbacks, such as the inherently toxic nature of most molten salts. However, molten salt reactors provide more flexibility for the use of nuclear fuel, which enables these reactors to keep running and have longer operating cycles until the reactor has to be taken offline for maintenance. Molten salt reactors can also be used for disposal of the spent fuel from LWRs as the spent fuel is no longer useful in LWRs, but a molten salt reactor can help diminish LWR nuclear waste by using it as fuel.

Carasik, who one day hopes to become a tenure track professor or staff scientist at a research university or national laboratory, hopes that his work will give back in an important way.

“Ultimately I got into this because I would like to benefit society,” Carasik said. “Everyone wants to benefit society, but even the small little beneficial pushes like this are a move in the right direction.”

2016 ANS Conference Presentations:

"Feasibility Studies on a Hexagonal-Lattice Core for a World-Class Cold Neutron Source at NIST" by Dylan M. Prevost

"Turbulence Model Study for Pressure and Velocity Distributions for Molten Salts in a Crossflow Tube Bundle" by Lane B. Carasik - Won Best Graduate Presentation in the Thermal Hydraulics track

"Sensitivity study of PWR Upper Vessel flow and phenomena using RELAP5-3D" by Timmy Crook

"Development and Verification of Matlab Functions for Pressure Drop Estimation in Crossflow Tube Bundles" by Jonah B. Haefner

"Depleted Uranium Soaring Temperature Reactor (DUSTR)" by Jacob T. Landman and Mason Childs

"Design of Thorium Fuel in Current Light Water Reactors" by Joshua P. Smith, Jessica Taylor, Sierra Sanders and Connor Jarvis.

Monte Carlo Simulations and Experimentation of Hindlimb Mice in Chronic Low Dose Environments" by David. H. Saucier

For those further interested in work regarding molten salt reactors, see below:

References: