A new lightweight, energy-efficient tool for analyzing a material’s chemical makeup could improve the detection abilities of various technologies, ranging from bomb-detecting drones to space rovers searching for signs of life, says a Texas A&M University biomedical engineer who is part of the team developing the instrument.

The tool makes use of optical communications fiber to collect and transmit light as it interacts with the material being studied, explains Vladislav Yakovlev, professor in the Department of Biomedical Engineering at Texas A&M. Compared with conventional technology, the newly designed measurement system is 95 percent lighter, requires 65 percent less energy and is only about a third of the cost, he says. The system is detailed in the latest issue of the scientific journal Proceedings of the National Academy of Sciences.

Perhaps just as important, because of the way in which the system is constructed, it’s significantly sturdier than current technology, Yakovlev notes. This increased robustness, coupled with a massive reduction in the system’s overall weight and decreased energy requirements, makes the technology a prime candidate for integration into lightweight unmanned aircraft vehicles used for remotely sensing explosives, he says. But Yakovlev’s technology is not limited to terrestrial applications; those same attributes make the system an ideal tool for use on space-based vehicles where mechanical shocks and excessive vibrations associated with the launchings and landings have often damaged analysis technologies, Yakovlev notes.

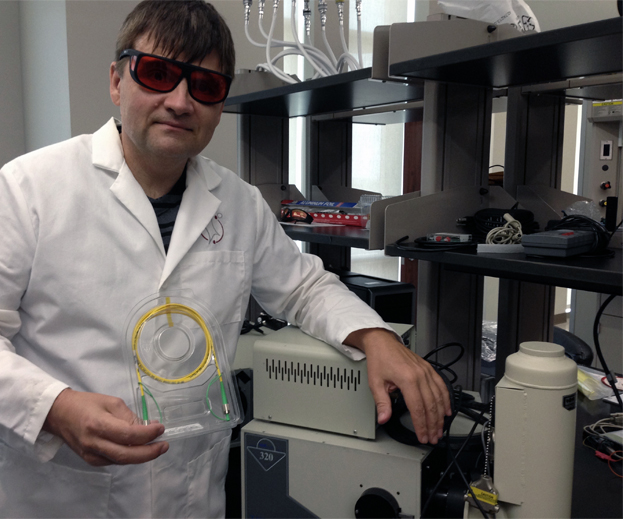

[By using a simple optical fiber, Professor Vladislav Yakovlev is eliminating the need for bulky and costly spectrometers (shown on his left).]

In essence, Yakovlev’s system is a “better mousetrap” – a reinvention of a technology known as Raman spectroscopy. Raman spectroscopy is a widely used, nondestructive method for performing chemical analysis of a material. It involves analyzing a spectrum of light as it interacts with the molecules of a material. During this process, researchers shine light – typically a laser – on a material. As that light interacts with the molecules of that material, it scatters and changes color in a unique way, depending on the material itself. Because the resulting spectrum is unique to the material, it serves as a sort of “fingerprint” by which researchers can identify the exact chemical composition of that material.

However, the Raman effect is too weak to see with the naked eye, so researchers use a device known as a spectrometer to collect and analyze the scattered light. Although extremely effective, spectrometers, Yakovlev explains, are costly, delicate and require large amounts of energy to power them – all characteristics that limit their use in extreme conditions.

With this in mind, Yakovlev and his team went about building a lightweight and energy-efficient Raman measurement system that did not require a spectrometer. The fiber-based setup they developed, Yakovlev explains, is capable of highly sensitive signal detection by using optical fibers to collect and transmit light as opposed to allowing the light to pass through lenses, as is the case in conventional Raman spectroscopy. The network of fibers, he adds, can be securely and rigidly attached to a small detector (a device known as a photomultiplier), enabling the entire apparatus to become resistant to mechanical shocks because there are no moving parts.

“We looked at how you disperse light and how you then analyze light,” Yakovlev said. “Instead of using the traditional spectrometer we are using an optical communications fiber to collect and transmit the light. Then we use a standard detector that is commonly used in biomedical and military applications to analyze the arrival time of photons. The detector has a short time response, so it’s fast, and there is no need for a spectrometer. Any application that involves using such a device for a long period of time with no access to an energy source would benefit from our technology.”

Joining Yakovlev in this research effort are Professor Marlan O. Scully of Texas A&M, Princeton University and Baylor University; Associate Professor Javier Jo of Texas A&M; Professor Kevin K. Lehmann of the University of Virginia; Texas A&M Engineering Experiment Station Research Engineer Georgi I. Petrov and Shuna Cheng and graduate student Zhaokai Meng of Texas A&M.

About the Department of Biomedical Engineering

Committed to solving the world’s greatest health problems through the exploration of new ideas, integrated research and innovation, the Department of Biomedical Engineering at Texas A&M is producing the next generation of biomedical engineers, developing new technologies and new jobs, and achieving revolutionary advancements for the future of health care. The department has unique strengths in regenerative engineering, medical augmentation, molecular diagnostics/theranostics, tele-health, and precision medicine, and its faculty members are internationally recognized with collaborative relationships that span engineering, physical and natural sciences, medicine and veterinary sciences.

Contact: Professor Vladislav Yakovlev at (979) 458-2326 or via email at yakovlev@tamu.edu or Ryan A. Garcia at (979) 979.847.5833 or via email at ryan.garcia99@tamu.edu.