For Dr. Chad Mashuga, assistant professor in the Artie McFerrin Department of Chemical Engineering at Texas A&M University, explosive conditions create valuable learning opportunities. He pursues experimental process safety in the research of perfect storms: scenarios involving varieties of dust that create powerful bursts of energy and fire when stressed by other factors. Mashuga joined the department in 2014 after having contributed 15 years of related expertise for The Dow Chemical Company and BASF.

For Dr. Chad Mashuga, assistant professor in the Artie McFerrin Department of Chemical Engineering at Texas A&M University, explosive conditions create valuable learning opportunities. He pursues experimental process safety in the research of perfect storms: scenarios involving varieties of dust that create powerful bursts of energy and fire when stressed by other factors. Mashuga joined the department in 2014 after having contributed 15 years of related expertise for The Dow Chemical Company and BASF.

As a faculty fellow with the Mary Kay O’Connor Process Safety Center, Mashuga feels his research remains timely.

“Dust hazards are not always recognized and accidents do occur," he said. "Attempts to understand dust explosions from a more fundamental standpoint are worthwhile."

As reported by the U.S. Chemical Safety and Hazard Investigation Board, between 1980 and 2005 there were 281 combustible dust incidents that led to the deaths of 119 workers, injuries to 718 and extensive damage to numerous industrial facilities.

Given the prevalence of solids as raw materials or as intermediates in production and manufacturing, Mashuga wants to advance the fundamental understanding of the ignition, combustion and explosion processes of these materials.

For such an explosion to occur, there must simultaneously exist an oxidizer, ignition source and a dispersed combustible dust in confinement. While metals are typically not viewed as explosive, during manufacturing shavings, granules and dust often form from even common materials such as aluminum and iron. The resulting metallic explosions are brilliant, said Mashuga.

Similarly, dust explosion potential can be hidden in common items such as cornstarch, coffee creamer, grains, paper and dyes which can create a flash fire if a proper particle cloud is formed and an ignition source is available.

Mashuga studies permeations of the dust fuel in these explosions; for example, the impact of size distribution and chemical structure. His research in this area shows that traditional reporting of size distribution can be inadequate and suggests an alternative that better represents the true dust hazard.

He has examined methodologies in preventing dust explosions. In 2014, Mashuga published research on the fundamental nature of inert dusts as a means to extinguish dust explosion hazards.

“I am also suggesting new ways of using existing test equipment to have alternative mitigation strategies for dust explosions, at more pertinent process conditions,” said Mashuga.

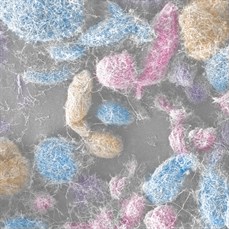

Illustration: Carbon nanofiber agglomerates studied for dust explosion material.