Sponsor: Dr. Sarah Frommer and Dr. Yi-Chun Carol Liu, both from Texas Children’s Hospital

A team of five students worked to find new and adaptable solutions to infant ear deformations — where all the material is there, just not in the right place.

Project need: Newborn infants with ear deformations need to have the problem remedied quickly, as an infant’s ear is only malleable for about the first three months after birth. Current devices on the market do not provide a customizable fit, which can cause small little abrasions or irritations and make them difficult for parents to work with. However, if the infant does not receive the treatment, plastic surgery may be necessary.

“It might to some people just be considered a cosmetic procedure, but it actually can cause a huge psychological toll on that child as they're growing up. In severe cases, it can lead to hearing loss,” said Ivanna Arizpe. “That's something that we want to limit and resolve the problem before anything can cause them harm.”

Darby Ballard said interacting and building relationships with both sponsors made a world of difference throughout the project.

“You can never forget that part of engineering is creativity. Being able to take something from concept to prototype and integrating your own twists on that in the way that you want, I think that aspect is something that I was starting to forget prior to this project,” Ballard said.

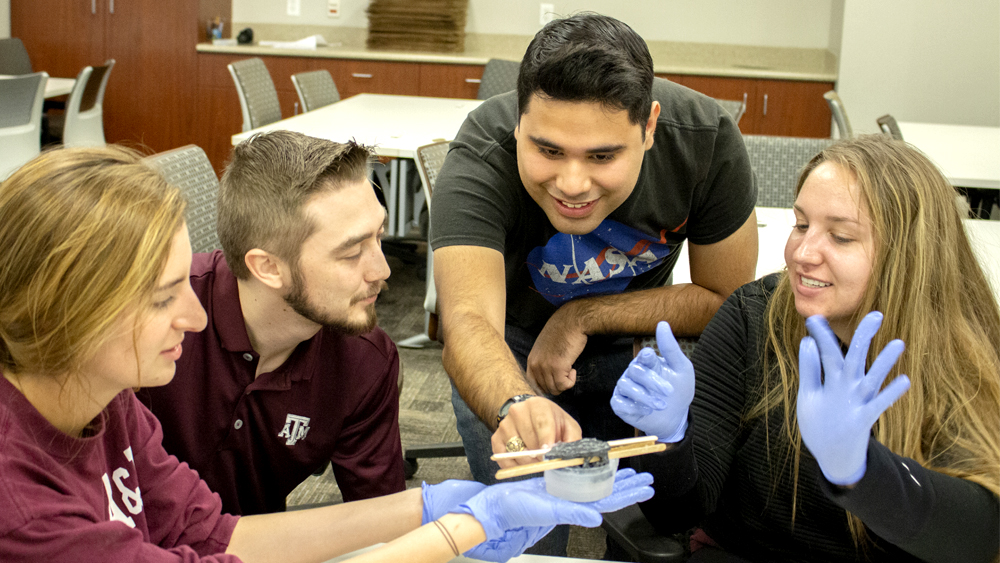

Solution: The team developed a way to 3D print a personalized treatment plan to create alternative devices to the generic products on the market. The team had the chance to travel and meet with an actual patient, even having the opportunity to scan an infant’s ear for reference.

“This is the application of our education, and seeing it and being successful with it helps me know that in the future, wherever, whatever I do with my life, I will be able to achieve something like this because I've already seen results,” Makarczyk said.

Challenges: Before they could create the device, the team first had to develop ways to scan, mold and 3D print the ear effectively. Challenges included finding ways to effectively make a scan of an ear and develop a process that health professionals will feel comfortable using.

“We need to find a way to make this process easy and manageable for doctors to do so they're not scared to approach this treatment plan,” said Kyle Robinson. “The learning curve is very quick. We’ve really made it a focus because even if we come up with the best device, it's not going to ever be accepted if doctors have no idea how to use it.”

Broader impact for students: Jacob Rodriguez said he could already see how the skills he’s gained from the project can be reworked into life after graduation.

“Studying medical devices in class is one thing, but if you have a hands-on experience, you get more of an idea of how to apply your skills in the real world and how to work better with the team,” Rodriguez said. “We’ve gotten to see how a medical device we make can help people live better lives. That’s a pretty rewarding experience.”