Advances in both hardware and software infrastructure make it possible to carry out realistic simulations of materials that can lead to a better understanding of their behavior. Leveraging these advances, the Computational Materials Science Summer School (CMS3) at Texas A&M University aims to train students in some of the most advanced and widely used computational materials science simulation tools.

A three-year, $500,000 grant from the National Science Foundation (NSF) opens up the possibility of upscaling the school to include more participants, expanding the curriculum, introducing immersive visualization through virtual and augmented reality tools, and providing shorter, in-depth seed courses.

Under the direction of Dr. Amine Benzerga, professor in the Department of Aerospace Engineering at Texas A&M, CMS3 has been training students on computational simulation tools during a 10-day summer school for seven years.

Simulations are one of the key ingredients used to realize the Materials Genome Initiative, which was designed to support United States institutions in the effort to discover, manufacture and deploy advanced materials that are essential to economic security and human well-being, faster, and at a reduced cost. CMS3 will contribute to this mission by training the scientists and engineers who will discover and develop the materials to make technologies of national importance possible.

CMS3 helps to push the thriving field of computational materials science (CMS) by providing up and coming researchers with a broad exposure to as many computational techniques as possible. The training provided will equip the participants with the knowledge and skills necessary to push the frontiers of simulation-enabled materials research.

The NSF award leverages existing cyberinfrastructure to expand participation, including those from underrepresented groups, through local and remote training. While the summer school can only accommodate 20 students on-site, with the addition of remote capabilities the class size can be expanded to include 80 remote graduate and postdoctoral researchers, including industry participants.

“In short, the idea is to equip a new generation of materials scientists with state-of-the-art computational models in a very original way,” says Benzerga.

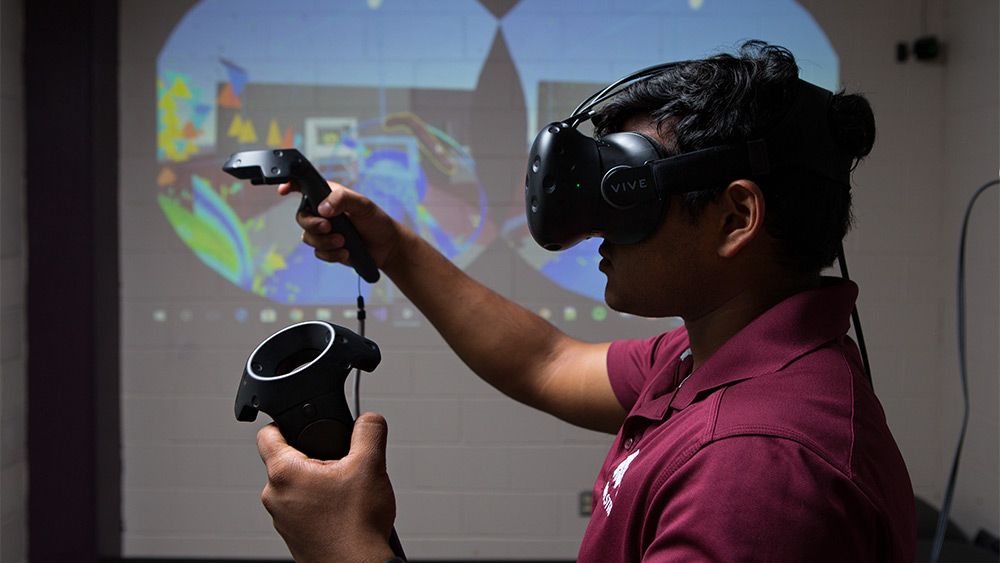

Included in the expansion of the school will be the introduction of immersive visualization through virtual reality (VR) and augmented reality (AR) tools to help students with different backgrounds and learning styles interpret complex material data. For this portion, the Immersive Mechanics Visualization Laboratory run by Dr. Darren Hartl, assistant professor in the Department of Aerospace Engineering, will be employed.

“It is challenging for graduate students to analyze very large amounts of data that come from the supercomputer during materials simulations,” said Benzerga.

The idea is to use AR and VR to help students better visualize the resulting simulations. “Sometimes better visualization not only leads to better

Another goal will be to expand the CMS network of experts among national laboratories and academic, domestic and international institutions who will contribute to the teaching efforts in the areas of continuum micromechanics, mesoscopic simulation

Benzerga would also like to expand the school to include shorter seed programs in specialized areas offered at different times of the year. “The paradigm is that there is a horizontal theme and a vertical theme,” he said. So far the paradigm has been horizontal. We teach multiple codes, but the students don’t get the chance to go very deep in their learning with any particular one.”

The specialized classes will run three to five days, giving experts the time to teach one particular computational method with much more depth. Benzerga envisions the first year to be for on-campus participants only, with the possibility of adding remote accessibility in the future.

The overall project aims to train the scientists and engineers that will discover and develop the materials that will make technologies of national importance possible.