Ali Beheshti, Tanil Ozkan and Stephen Keen, tribologists from the Microtribodynamics Group led by Dr. Andreas A. Polycarpou, represented Texas A&M University’s Department of Mechanical Engineering at the student STEM camp held in May. The event was hosted by The Society of Tribologist and Lubrication Engineers (STLE) during its 70th annual meeting and exhibition in Dallas.

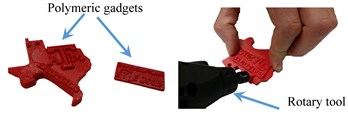

A map in the shape of Texas was printed using a 3D printer and joined to a commemorative ‘North Garland STLE 2015' label using frictional welding. The multifunctional (key chain + bottle opener) gadget was designed by mechanical engineering senior Yasushi Mizuno. Thin rods of PLA, a polymeric material commonly used in 3D printing, were applied along the edges of the commemorative level. The students then rubbed the material at above 1,500 rpm using a rotary tool. The friction between the two contacting polymeric surfaces at the high rpm generated enough heat to bring the thermoplastic polymer to its melting point. Students then combined the created polymer puddle, adjusted the feed rate, and controlled the rotary movement using a hand tool, allowing them to create the desired weld line.

During the exhibition the capabilities of 3D printing technology were discussed with participating high school students. The North Garland High School students in attendance had already been exposed to 3D printing technology, and shared that they also believe it is a useful process for joining separate 3D printed pieces. The experiment and accompanying poster showed students how basic principles of frictional heat induced welding can be utilized in many of the complicated tasks facing today’s manufacturing technology industry. The process has direct applicability to products ranging from consumer electronics to aerospace applications.